High Quality Double Sided Tape Die Cutting Line

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai port, China, Ningbo port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20 sets/year |

| Supply Ability: | 20 sets/year |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE certification |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai port, China,Ningbo port |

High Quality Double Sided Tape Die Cutting Line

High Quality Die Cutting Line is mainly used for backlight production line, CNC hole production line, specially used for multi-hole die-cutting products, using Japanese servo motor, touch screen control panel and PLC program control, combined with American technology, Japan, Korea, Taiwan made High precision die cutting machine, Operate Flexibly Die Cutting Line on the market has been widely used.

Robotization Die Cutting Line's unique small hole positioning and timely correction function ensures repeated die-cutting and accurate positioning

High Quality Die Cutting Line is suitable for various molds, corrosion molds, engraving molds, hardware molds, QDC composite molds, and solve various complex processes.

|

SPECIFICATIONS FOR HIGH SPEED PRECISION FLATBED DIE CUTTING MACHINE

|

|

|

|

|||

|

Model

|

ENZO-200

|

Maximum Feeding Speed

|

30 mm/min

|

|||

|

Press Force

|

5T

|

Feeding Accuracy

|

< 0.1 mm

|

|||

|

Cutting stroke

|

24 mm

|

Feeding Roller

|

PU/NBR

|

|||

|

Maximum Running Speed

|

300 times/min

|

Feeding Driven

|

Servo Motors

|

|||

|

Stroke Adjustment

|

±5 mm

|

Lubricate method

|

Fully Automatic Central Lubrication System

|

|||

|

Shut Height of Stell Mould

|

105 mm

|

Protection

|

3 Optical Safety light curtain

|

|||

|

Maximum die cutting size of Steel Mould(L*W)

|

120 x 150 mm

|

Power Supply

|

380v 3.5kw

|

|||

|

Turning Way

|

Electrically Adjust

|

Machine Weight

|

1000 kgs

|

|||

|

Press Style

|

Jog/Single/Continuous

|

Air Source Specification

|

0.5-0.6 mpa

|

|||

|

Type of Mould

|

Plastic board mould, Chemical sculpture mould, Metal mould

|

Maximum size of mode(L*W)

|

200 x 180 mm

|

|||

|

Maximum Feeding width

|

200mm

|

Machine Size (L*W*H)

|

1200 x 900 x 1250 mm

|

|||

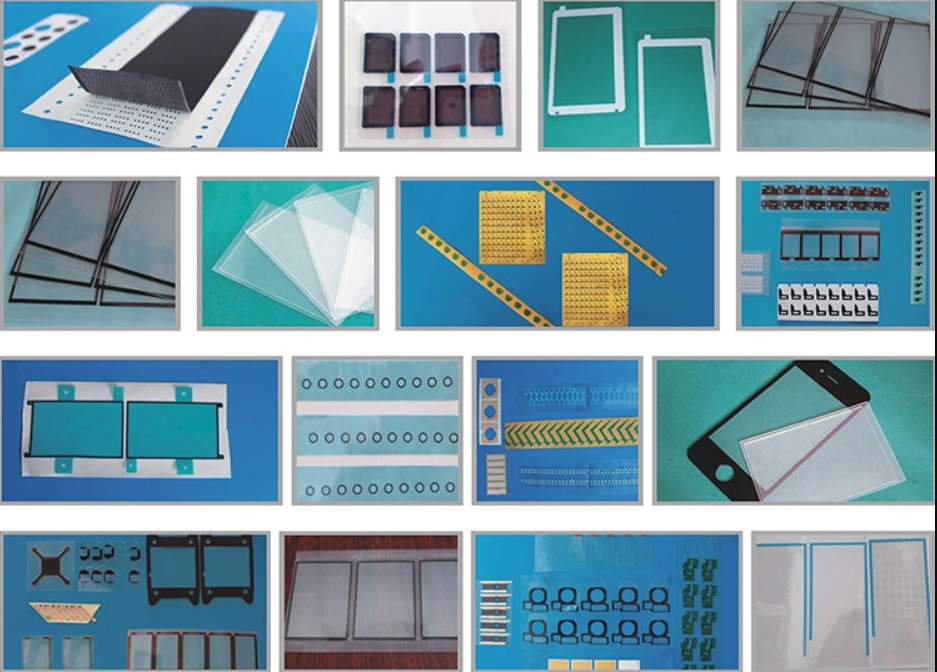

Our Perfect Durability Die Cutting Line are widely applied in laminating, slitting and die-cutting for all kind of spare parts in Mobile phone, Laptop, LCD, TV, Medical, Camera, Wearable, E-label, Car and printing etc.

Our precision die cutting machine is suitable to die cut the thin flexible electrically insulating materials such as plastic films, rubber, fibers, and papers. These materials include polyimide films, Mylar PET film, polypropylene, aramid fiber, insulation papers (aka fish paper), PTFE, solid rubber sheets such as silicone, neoprene, and many more etc.

After Sales Service

Related Keywords