Economic Angle Hot Blade Cutting Machine

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main Port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 50pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 84411000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main Port,China |

Economic Angle Hot Blade Cutting Machine

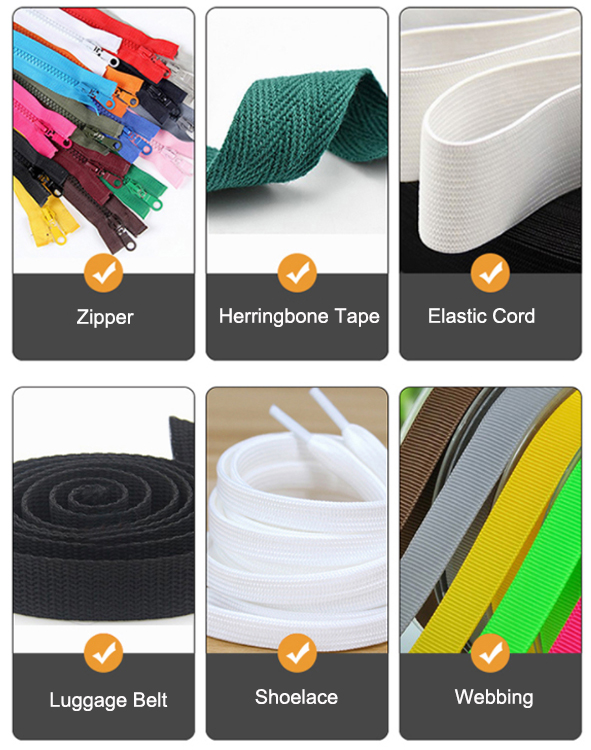

Flying Man automatic roll to sheet cutting machine can cut material including: ribbon, elastic band, Velcro, adhesive buckle belt, woven belt, nylon ribbon, color ribbon, backpack belt, shoelace, woven network tube, telescopic network tube, etc. High precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation. This automatic webbing hot cutting machine is simple and practical, saving a lot of manpower and material resources.

Product Parameters

|

Automatic Hot and Cold Tape Materials Cutting Machine

|

|

|

|

Model

|

FMHD-100T

|

|

|

Cutting length

|

0.1 mm-9999.9 mm

|

|

|

Cutting Width

|

Max. 103 mm

|

|

|

Cutting thickness

|

0.1-5 mm

|

|

|

Cutting speed

|

110 pieces/min

|

|

|

Power

|

450W

|

|

|

Voltage

|

110V/220VAC 60HZ/50HZ

|

|

|

Machine Weight

|

23 kgs

|

|

|

Machine size

|

560 x 430 x 400 mm

|

|

|

Feeding speed

|

Adjustable

|

|

|

Cutting tolerance

|

1% x cutting length

|

|

|

Temperature

|

350 degrees Celsius

|

|

- Upgrade the direct drive motor.

- High precision, small error.

- Automatic alarm after finished the working.- Energy saving and save electricity.

- Strong and durable.

- Lack of material stop automatically.

- Hot function or Cold/hot function

- High speed feeding.

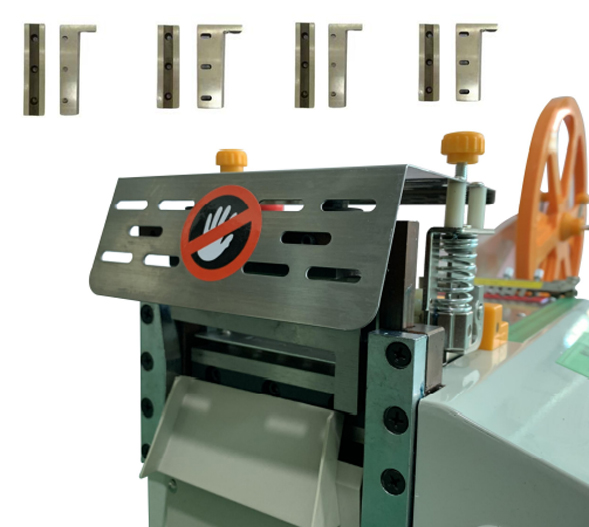

Cutting knife speed and feeding speed are adjustable. High speed steel knife can cut ultra-wide materials.

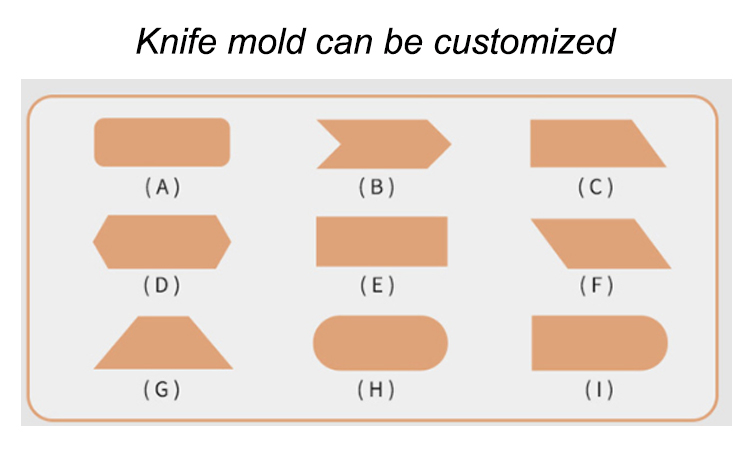

Knife mold can be customized, choose one of above to meet your production requirement. Standard version is straight cut, for angle cut, please check with us for the additional cost.

Upgraded Motors

- High-precision electric motor control cutting precision.

- Power flow strong, feeding materials quickly.

- Upgraded motors have longer operating life.

Control panel

- Chinese-English buttons and operation screens.

- Setting length, speed, quantity freely.

- It’s easy to understand and operation.

Material induction

- No material monitoring.

- Automatic shutdown.

Cooling fans

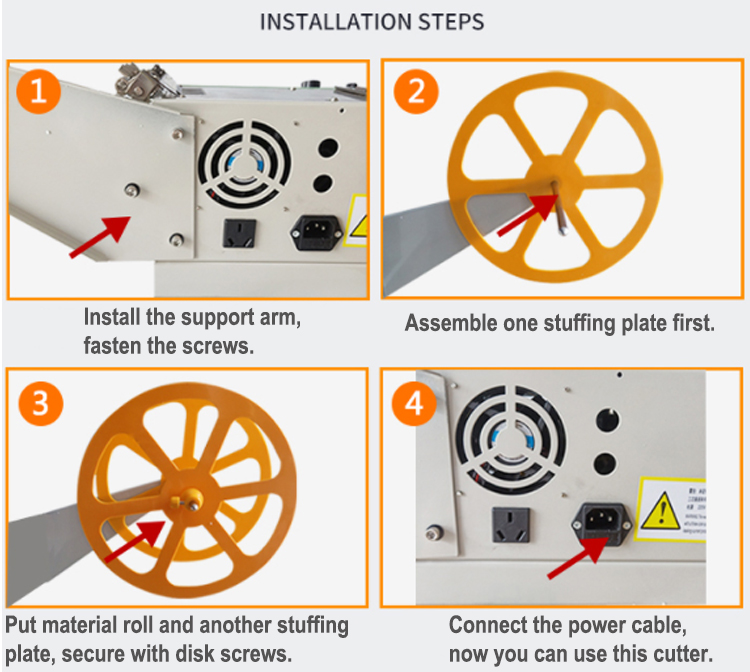

Stuffing plate.

With the function of clamping material, prevent material scattered, fall off, resulting in smooth material cutting and slow

speed, etc.

Product Application

Flying Man automatic roll to sheet cutting machine can be used to straight cut or multi-angle cut for many kinds of materials.

Applicable industry: suitable for clothing, footwear, packaging, electrical appliances, home textiles, tents, cloth and other industries.

Training service

After Sales Service

Related Keywords