Automatic cutting machine roll to sheet

-

$6200.001-5 Piece/Pieces

-

$6000.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 60pcs/minute |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8477800000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Feature

Main functions

- Preset total cutting quantity.

- Preset cutting length.

- Preset cutting speed.

- Preset cut quantity each time ( applied for hot cutting).

- Display cutting quantity finished.

- Half cut-off with multi-cut.

- Full cut-off with one-cut.

- Five different cutting length can be set.

- Different cutting quantity and circulation time can be set.

- Return to ZERO.

|

SPECIFICATIONS FOR AUTOMATIC ROLL TO SHEET CUTTING MACHINE

|

|

|

||

|

Model

|

FMKY-360Q

|

|

||

|

Cutting length

|

0.1~9999.9 mm

|

|

||

|

Cutting Width

|

0-360 mm

|

|

||

|

Cutting speed

|

0-130 cuts/min

|

|

||

|

Cutting precision

|

±0.05 mm

|

|

||

|

Power

|

1.5 kw

|

|

||

|

Voltage

|

220 v/380 v

|

|

||

|

Counter

|

Meter counter + Speed Display Board

|

|

||

|

Machine Sizes (L*W*H)

|

870x1050x1070 mm

|

|

||

|

Machine Weight

|

240 kgs

|

|

||

You can set all parameter in touch screen, such as the length, batch quantity, total quantity, cutting speed, etc.

It's convenient for workers to operate the machine.

Material: SKH-51

Original: Japan

Lifetime: About 20 million times cuts.

Scissor-type cutting blade, durable with highest hardness 65HRC. Easy to adjust, sharp, maintain and change.

Photo Sensor

Kiss cutting

This unit can finish kiss cutting .Below anvil is connected with springs, which could absorb shock and make sure the kiss cutting

well. Easy to adjust and maintain.

Automatic unwinding device

This unwinding device is controlled by motor, you can adjust the speed.

It has sensor to send the material automatically. It could supports about 30KG weight. inflatable air shaft with 3 inch OD.

Training service

After Sales Service

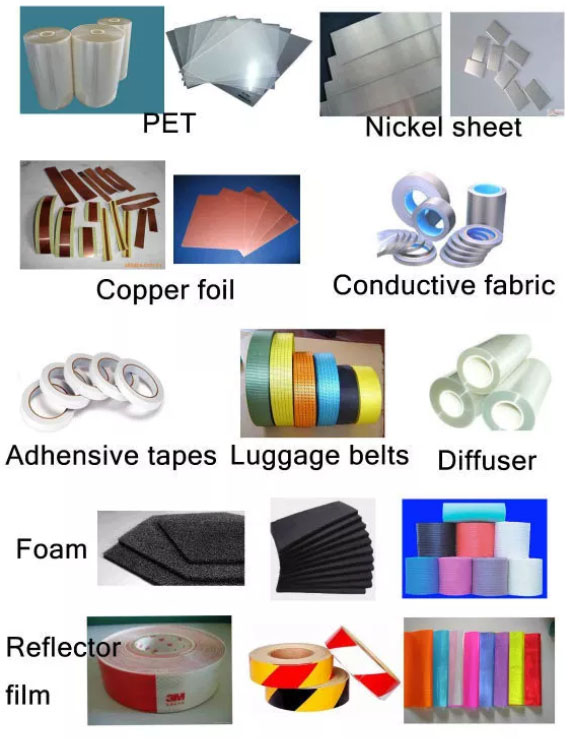

Related Keywords