High Quality Automatic Honeycomb Paper Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10 sets/month |

| Supply Ability: | 10 sets/mongh |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 84411000 |

| Transportation: | Ocean |

| Port: | Main port, China |

High Quality Automatic Honeycomb Paper Machine

This automatic honeycomb paper machine is suitable for cutting honeycomb paper, geami wrapping paper, shock-absorbing paper, fish net paper from 70g to 120g.

Feature of honeycomb paper making machine

- The unwinding, cutting and rewinding in one process.

- Main motor equipped with Inverter for speed regulation.

- Automatic ultrasonic web guide controller for unwinding.

- Tension controlled by magnetic powder brake and clutch.

- Automatic meter counting device, automatically stop after it reaches the length you set.

- Pneumatic cylinder to control the cutting mould up and down.

- Roll to sheet cutting is optional.

Product Parameters

SPECIFICATIONS FOR HIGH SPEED HONEYCOMB PAPER MAKING MACHINE

|

Model |

FMKY-500A |

| Max. unwinding width | 600 mm |

|

Max. unwinding roll diameter |

1200 mm |

|

Max. rewinding width |

600 mm |

|

Max. rewinding roll diameter |

300 mm |

|

Rewinding shaft(steel bar) |

1”/1.5”/2”/3”(only provide one size) |

|

Running speed |

80-100m/minute |

|

Power |

4kw |

|

voltage |

380v 3 Phase 5 wires |

|

Machine weight |

Approx. 1000kgs |

|

Machine size |

2620(L ) x 1640(W ) x 1160 mm(H) |

Product Application

Honeycomb paper is eco-friendly and cost-effective alternative for plastic bubble wrap cushioning. It is easy to stretch, softer and more flexible, provide cushion protect without surface scratch. Finished products from this honeycomb paper making machine can be used to pack fruits, flowers, ceramics, glassware, etc.

Training service

After Sales Service

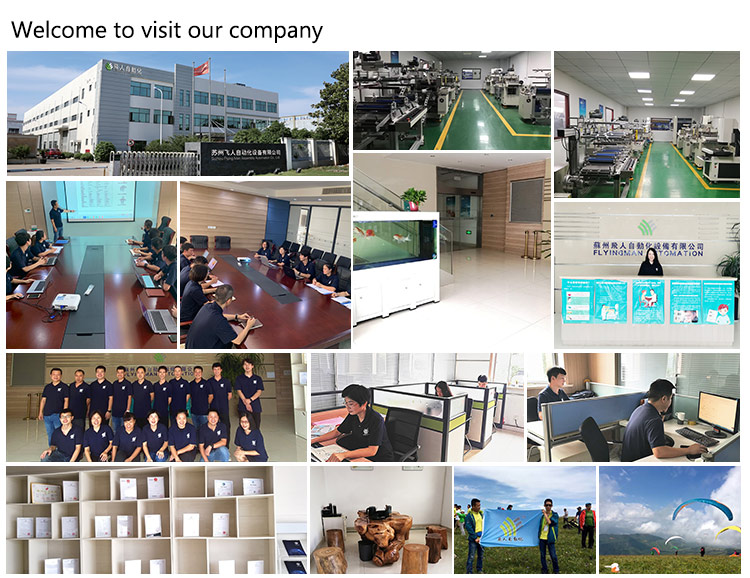

Q: Are you a factory or trading company?

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: Is there a branch or after-sales service point abroad?

A: We have a branch in Vietnam and we can provide after-sales service in Vietnam.

Q: How about package?

A: High quality PE film will be covered on machine body before putting the plywood wooden carton. It's easy for forklift to upload and download. Safety transportation.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Q: What is the terms of payment you accept?

A: We can accept the T/T payment, we need 30% of total amount as deposit and 70% balance should be paid before delivery, we can also accept the L/C, PayPal, Private account, Cash and others.

Q: What about the warranty?

A: All of our machines have 1-year warranty, if need, we can send engineer to install and test to your factory, buyer should pay for the round air-tickets, food, hotel and transport, and also pay our engineer 100 USD / day / person as salary.

In warranty period, if spare parts broken, we exchange them free. after the warranty period, we supply the machine’s full life service, buyer should pay for the material cost of exchanging spare parts and repairing.

Your question will be highly appreciated.

Related Keywords