Manual Pizza box Flatbed Die Cutting Creasing Machine

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 30pcs/month |

| Supply Ability: | 30pcs/month |

| Payment Type: | L/C,T/T,Negotation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| Transportation: | Ocean,Land,Air |

| Port: | Main port, China |

Manual Pizza box Flatbed Die Cutting and Creasing Machine

Flying Man die cutting and creasing machine is a special equipment for creasing and cutting cardboard, corrugated board, plastic and leather, applicable for printing packaging decoration and plastic industries. Manual pizza box flatbed die cutting and creasing machine is characterized by its compact structure, fine workmanship, high precision and easy and reliable operation, etc.

|

Automatic Die Cutting and Creasing Machine

|

|

|

|

|

|

|

|

|

||||||||

|

Style

|

FMFW930

|

|

||||||||||||||

|

Inner chase size(mm)

|

930x660

|

|

||||||||||||||

|

Speed

(strokes/min) |

20±3

|

|||||||||||||||

|

Max. rule length(m)

|

<25m

|

|

||||||||||||||

|

Motor power

|

3.0kw

|

|

||||||||||||||

|

Total Weight

|

2800kgs

|

|

||||||||||||||

|

Machine size

|

1780x 1590x 1540mm

|

|

||||||||||||||

Advantages & Features

1. Sliding bearing adopts high quality copper alloy, resisting and shock absorption.

2. High degree of force of the free-wheel, high pressure.

3. Use high level material integral casting for high intensity machine.

4. Single plate electromagnetic clutch is sensitive and reliable safety.

5. Single pressing, continuous pressing, adjustable delay pressing.

Application

Flying Man die cutting and creasing machine is suitable for die cutting and creasing cardboard, corrugated board, plastic and leather, applicable for printing packaging decoration and plastic industries.

Technical Service

Training service

After Sales Service

Q: Are you a factory or trading company?

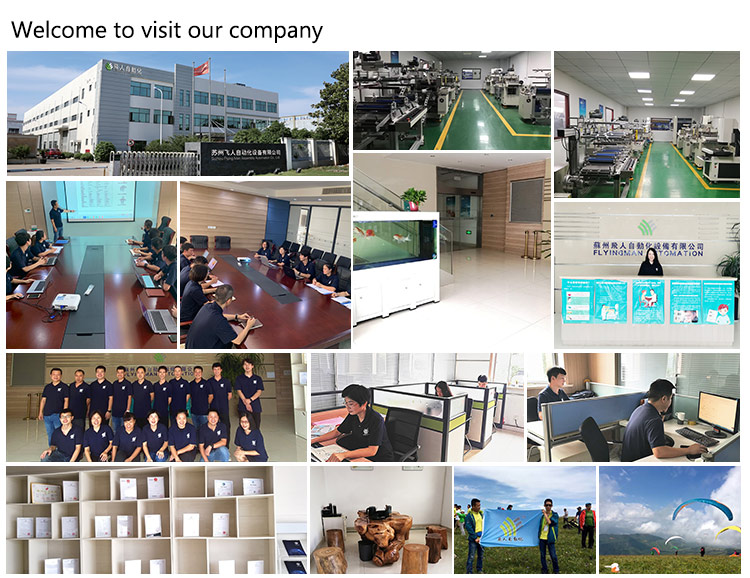

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: Is there a branch or after-sales service point abroad?

A: We have a branch in Vietnam and we can provide after-sales service in Vietnam.

Q: How about package?

A: High quality PE film will be covered on machine body before putting the plywood wooden carton. It's easy for forklift to upload and download. Safety transportation.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Q: What is the terms of payment you accept?

A: We can accept the T/T payment, we need 30% of total amount as deposit and 70% balance should be paid before delivery, we can also accept the L/C, PayPal, Private account, Cash and others.

Q: What about the warranty?

A: All of our machines have 1-year warranty, if need, we can send engineer to install and test to your factory, buyer should pay for the round air-tickets, food, hotel and transport, and also pay our engineer 100 USD / day / person as salary.

In warranty period, if spare parts broken, we exchange them free. after the warranty period, we supply the machine’s full life service, buyer should pay for the material cost of exchanging spare parts and repairing.

Related Keywords