Economical roll to sheet cutting machine

-

$2690.001-5 Piece/Pieces

-

$2590.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100pcs/month |

| Supply Ability: | 100pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

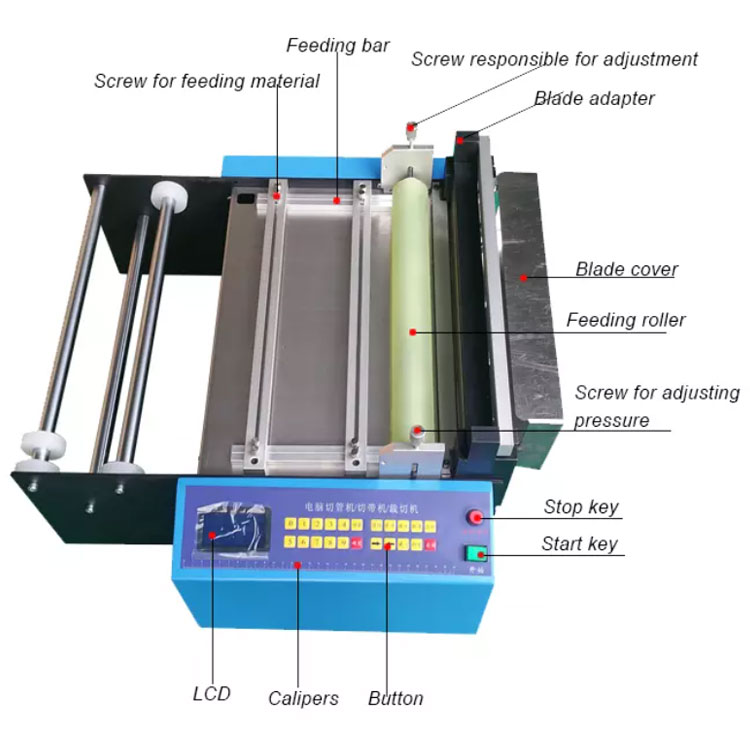

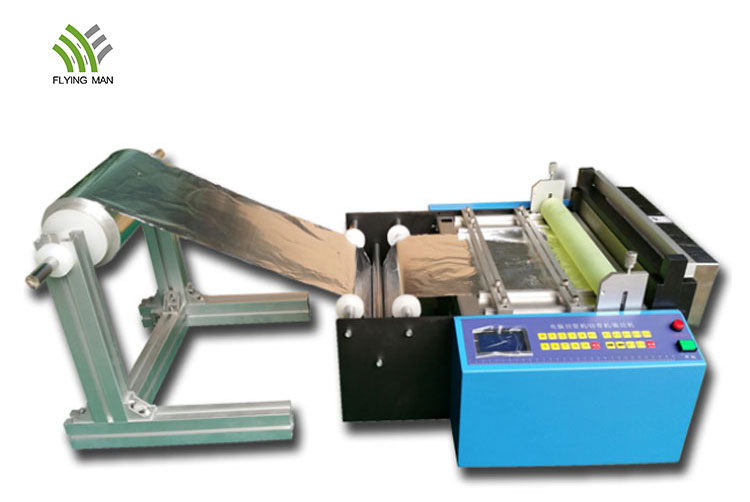

This economic roll to sheeter machine has below advantages: high precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation, saving a lot of manpower and material resources.

|

Fully automatic micro-computer cutting machine

|

|

|

|

|

||||

|

Model

|

FMHZ-600

|

|||||||

|

Cutting length

|

0.1 mm-9999.9 mm

|

|

|

|

||||

|

Cutting Width

|

0 - 610 mm

|

|

|

|||||

|

Cutting precision

|

0.1 mm

|

|

|

|

||||

|

Feeding speed

|

Adjustable, max. running 34 m/minute

|

|

|

|

||||

|

Power

|

0.85 kw

|

|

|

|||||

|

Voltage

|

220 v

|

|

|

|

||||

|

Machine Weight

|

75 kgs

|

|

|

|||||

|

Machine size

|

575 x 965 x 375 mm

|

|

|

|||||

|

Feeding motor

|

Stepper motor

|

|

|

|

||||

|

Cutting motor

|

250 W reducer motor

|

|

|

|

||||

|

|

||||||||

|

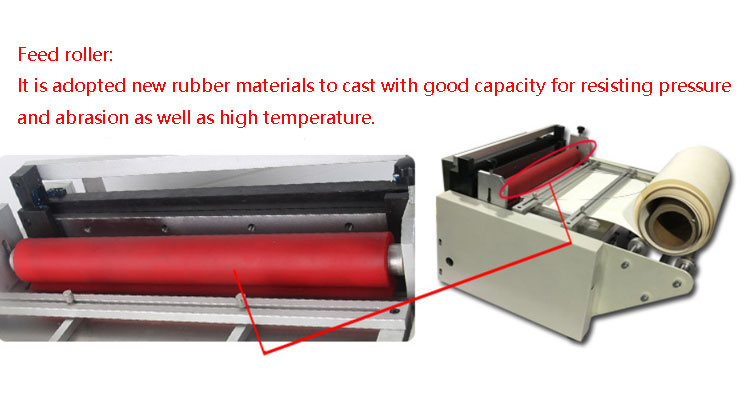

Feed roller

|

PUR: roller diameter 48mm, hardness 35 degree, the hardness of the lower roller is 75 degree

|

|

|

|

||||

|

Cutter material

|

SKD11

|

|

|

|

||||

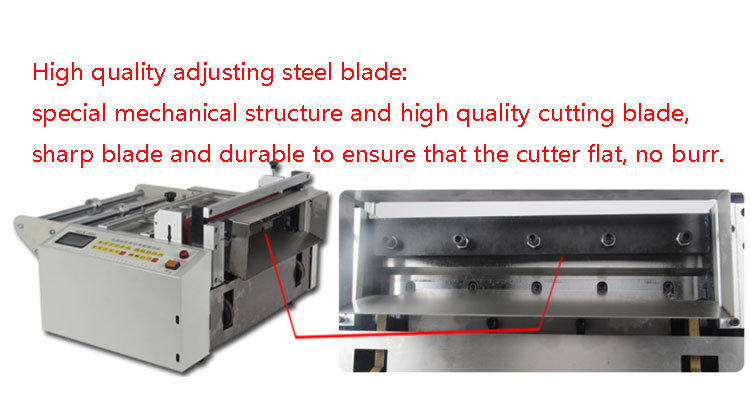

Performance Feature

Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

The length and speed can be adjusted continuously to achieve high efficiency.

Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

86 stepper motor ensure precise feeding, strong power, fast heat dissipation, speed, step length accurate control. And also ensure smooth/high precision cutting material with short time.

Advantages & Features

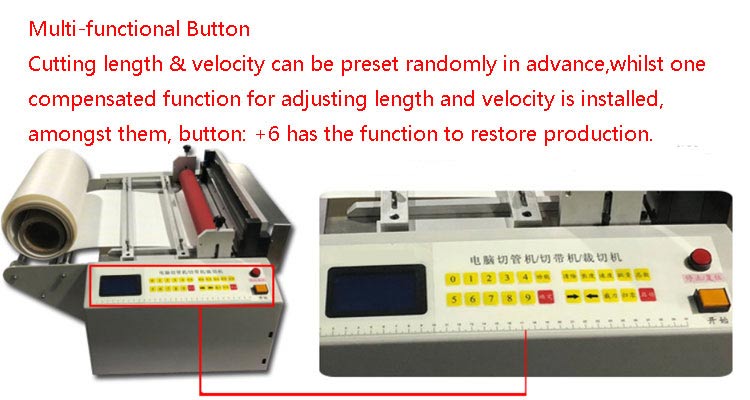

- Independent development of the special cutting machine motion control system is the core technology, which is suitable for all industries equipment fixed-length cutting.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- Set up automatic group accumulator and total accumulator count.

- Batch pause and delay time can be set.

It is adopted new rubber materials to cast with good capacity for resisting pressure and abrasion as well as high temperature.

After Sales Service

Related Keywords