Automatic hookah foil cutter machine

-

$2190.001-5 Piece/Pieces

-

$2090.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100pcs/month |

| Supply Ability: | 100pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Product Description

Product Description

Automatic hookah foil cutter machine/cross cutting machine

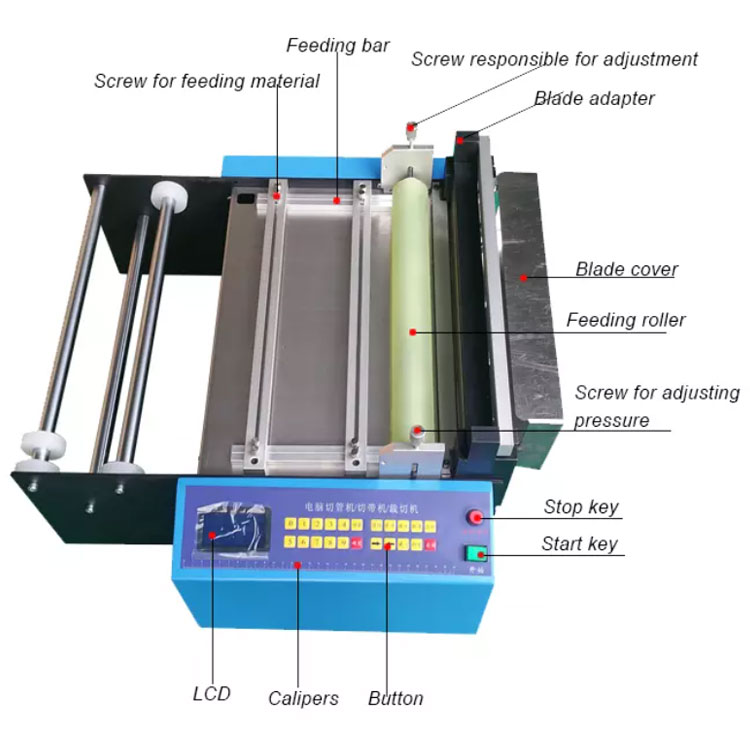

Flying Man automatic cross cutting machine adopts microcomputer numerical control display device, cutting length/quantity, feeding speed is set freely, add adjustable roller feeding mechanism, both sides automatically adjust the pressure and rise, can quickly release material, and prevent material damage effectively with thimble type feeding mechanism. This automatic roll to sheet cutter has below advantages: high precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation, saving a lot of manpower and material resources.

Product Parameters

|

Fully automatic cross cutting machine

|

|

|

|

|

||||

|

Model

|

FMHZ-400

|

|

||||||

|

Cutting length

|

0.1 mm-9999.9 mm

|

|

|

|

||||

|

Cutting Width

|

0 - 410 mm

|

|

||||||

|

Cutting precision

|

0.1 mm

|

|

|

|

||||

|

Feeding speed

|

Adjustable, max. running 34 m/minute

|

|

|

|

||||

|

Power

|

0.65 kw

|

|

|

|||||

|

Voltage

|

220 v

|

|

|

|

||||

|

Machine Weight

|

55 kgs

|

|

|

|||||

|

Machine size

|

640 x 670 x 360 mm

|

|

||||||

|

Feeding motor

|

Stepper motor

|

|

|

|

||||

|

Cutting motor

|

250 W reducer motor

|

|

|

|

||||

|

|

||||||||

|

Feed roller

|

PUR: roller diameter 48mm, hardness 35 degree, the hardness of the lower roller is 75 degree

|

|

|

|

||||

|

Cutter material

|

Imported SKD2 material blade

|

|

|

|||||

Performance Feature of Cross Cutting Machine

Special cutting tools

Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

Core technology

Independent development of the special cutting machine motion control system is the core technology, which is suitable for all industries equipment fixed-length cutting.

Timing, quantitative and fixed speed

The length and speed can be adjusted continuously to achieve high efficiency.

Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

Set up automatic group accumulator and total accumulator count.

Numerical control display device

This automatic cross cutting machine adopts microcomputer numerical control display device, cutting length/quantity and feeding speed can be set freely, add adjustable roller feeding mechanism, both sides automatically adjust the pressure and rise and fall. With thimble type feeding mechanism, it can be fast feeding.

86 stepper motor

86 stepper motor ensure precise feeding, strong power, fast heat dissipation, speed, step length accurate control. And also ensure smooth/high precision cutting material with short time.

Advantages & Features

- Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

- Independent development of the special cutting machine motion control system is the core technology, which is suitable for all industries equipment fixed-length cutting.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- Set up automatic group accumulator and total accumulator count.

- Batch pause and delay time can be set.

- Independent development of the special cutting machine motion control system is the core technology, which is suitable for all industries equipment fixed-length cutting.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- Set up automatic group accumulator and total accumulator count.

- Batch pause and delay time can be set.

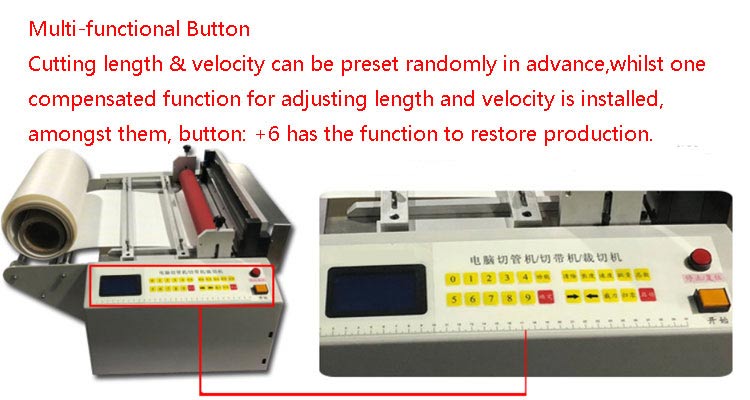

Multi-functional button

Cutting length & velocity can be preset randomly in advance, whilst one compensated function for adjusting length and velocity is installed, among them, button: +6 has the function to restore production.

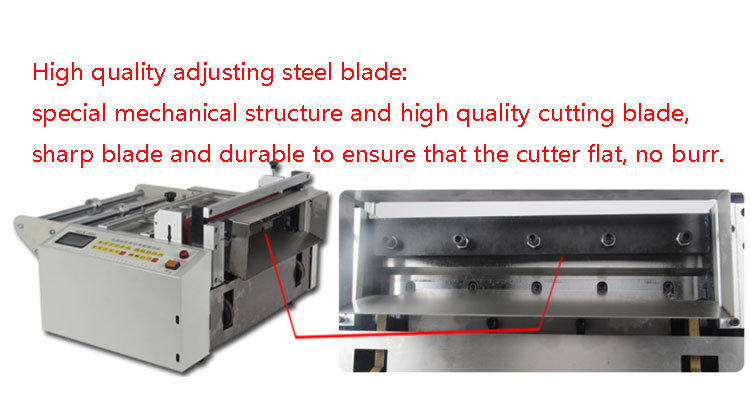

High quality adjusting steel blade

Special mechanical structure and high quality cutting blade, sharp blade and durable to ensure that the cutter flat, no burr.

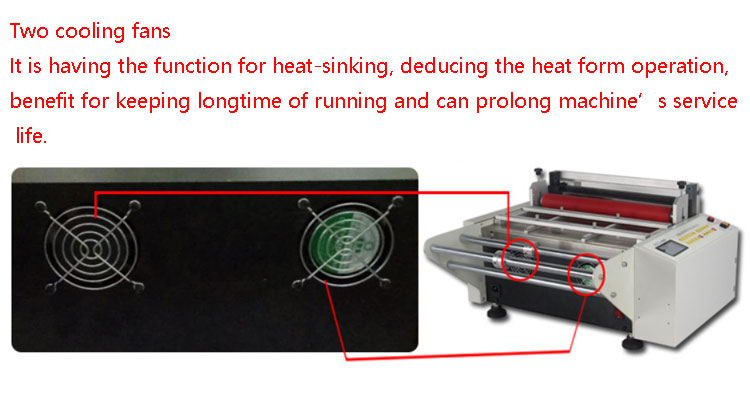

Two cooling fans

It is having the function for heat-sinking, deducing the heat form operation, benefit for keeping longtime of running and can prolong machine’s service life.

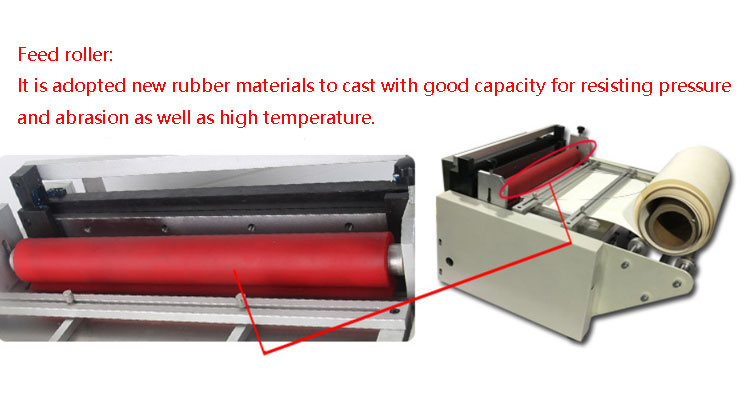

Feed roller

It is adopted new rubber materials to cast with good capacity for resisting pressure and abrasion as well as high temperature.

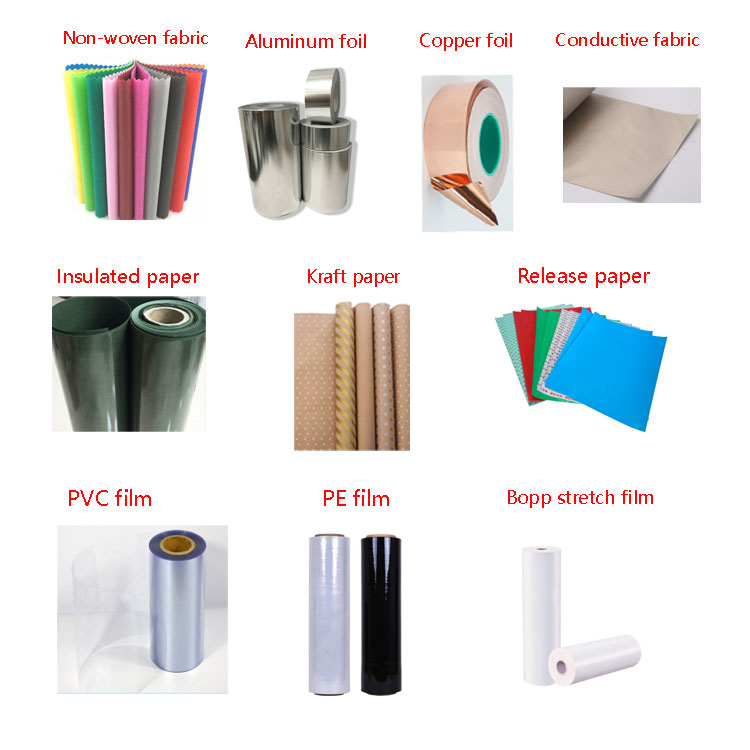

Product Application

Fully automatic cross cutting machine can be used for cutting non-woven cloth, wall paper, PVC film, reflective film, copper foil, aluminum foil, glass cloth, fiber cloth, mobile phone film, plastic slice, bubble film, flannelette and etc. This cutting machine system including FMHZ-400/FMHZ-500/FMHZ-600/FMHZ-700, cutting width from 1-710 mm, different model of cutting width is different, cutting thickness is also different. The maximum cutting thickness is 0.8 mm.

Automatic roll to sheet cutting machine is widely used in electronics industry, automobile and motorcycle parts industry, clothing and leather industry, electrical appliances, motors, toys, transformers and other industries.

Related Keywords

Related Keywords