Automatic aluminum sheet cutting machine

-

$8300.001-5 Piece/Pieces

-

$8100.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 50pcs/month |

| Payment Type: | L/C,T/T,Negotation |

| Incoterm: | FOB,CFR,CIF,EXW |

| HS Code: | 8477800000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Automatic cutting machine for aluminum sheet

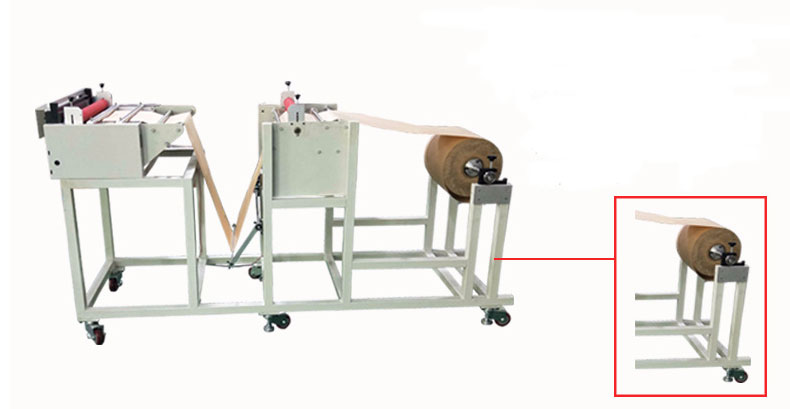

This all-in-one roll materials cutting machine adopts microcomputer numerical control display device, cutting length/quantity, feeding speed is set freely, add adjustable roller feeding mechanism, both sides automatically adjust the pressure and rise, can quickly release material, and prevent material damage effectively with thimble type feeding mechanism.

This automatic cutting machine mainly suitable for high speed cold/hot full/half cut strip.

High precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation, saving a lot of manpower and material resources.

|

Fully Automatic All-in-one Roll Materials Cutting Machine

|

|

|

|

|

||||

|

Model

|

FMHZ-1000A

|

|

||||||

|

Cutting length

|

0.1 mm-9999.9 mm

|

|

|

|

||||

|

Cutting Width

|

0 - 900 mm

|

|

|

|||||

|

Cutting precision

|

0.1 mm

|

|

|

|

||||

|

Feeding speed

|

Adjustable, max. running 36 m/minute

|

|

|

|

||||

|

Power

|

3.0 kw

|

|

|

|||||

|

Voltage

|

220 v/50 HZ

|

|

|

|||||

|

Machine Weight

|

220 kgs

|

|

|

|||||

|

Machine size

|

1700(L ) x1570(W ) x 1210mm(H)

|

|

|

|||||

|

Feeding motor

|

Stepping closed loop motor (high accuracy and less error)

|

|

|

|

||||

|

Cutting motor

|

Three-phase 220V Dever inverter motor

|

|

|

|

||||

|

|

||||||||

|

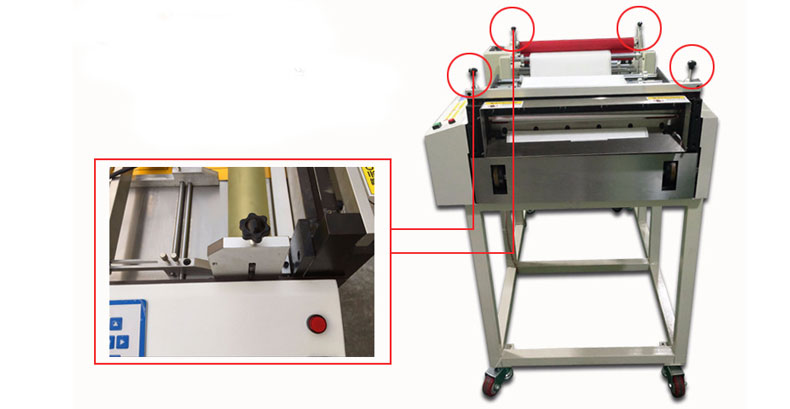

Feed roller

|

PUR: roller diameter 48mm, hardness 35 degree, the hardness of the lower roller is 75 degree

|

|

|

|

||||

|

Cutter material

|

SKD11

|

|

|

|

||||

Advantages & Features

- Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- Set up automatic group accumulator and total accumulator count.

- Batch pause and delay time can be set.

Function description

- Adjustable speed: 0-99mm

- Adjustable length: 0.1mm—9999.9mm

- Total amount set: 1—999999

- “Function” key + "0" key: cutting knife delay

- "Function" key + "1" key: cutting tool interval

- "Function" key + "2" key: Batch suspension

- "Function" key + "3" key: Length Compensation

- "Function" key + "4" key: Cutting speed

- "Function" key + "5" key: Setting step length

- "Function" key + "6" key: Restore the factory default Settings

Machine configuration.

- Spanner No. 3, No. 4, No. 5 (one for each)

- 1 pc back-up insurance control

- 1 pc instruction manual

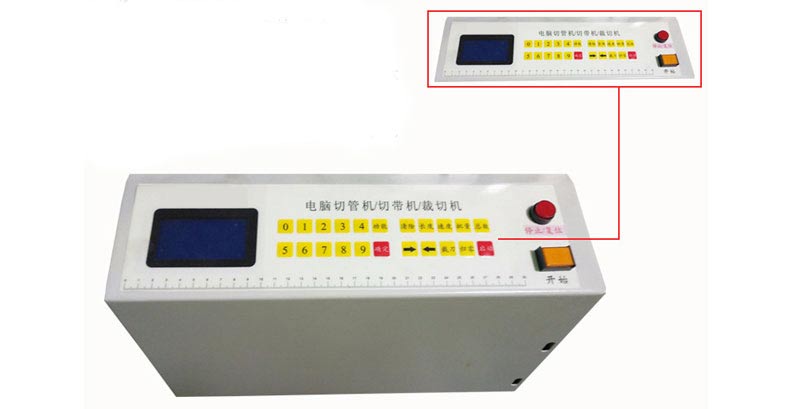

Control panel is very simple, simple operation, full Chinese/English LCD screen, easy to set the feeding length, speed, batch amount, pause time with compensation function, function key +6 can also restore production Settings and so on.

the knife.

With the function of heat exhaust, these two cooling fans can reduce the heat of the machine for long time production and prolong the service life of the equipment.

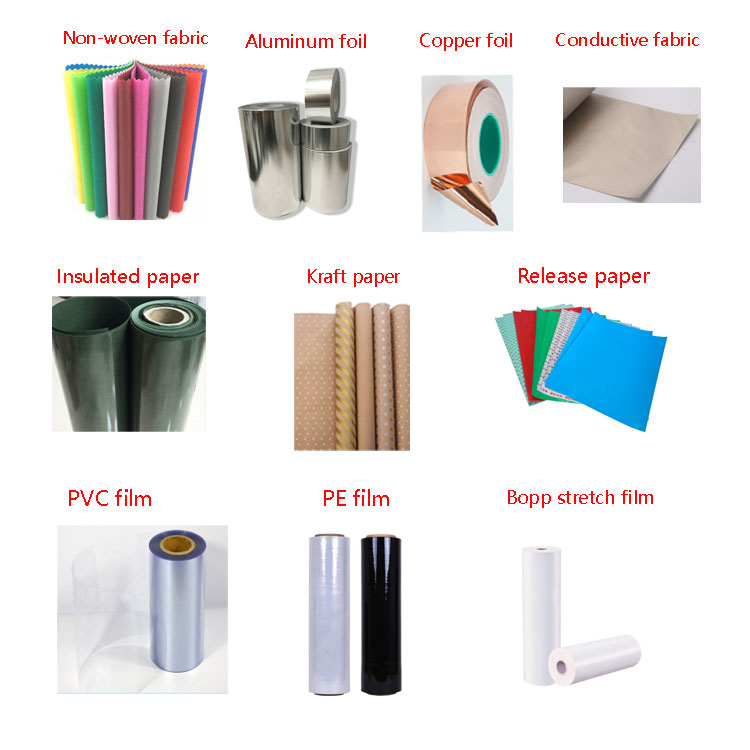

It is widely used in electronics industry, automobile and motorcycle parts industry, clothing and leather industry, electrical appliances, motors, toys, transformers and other industries (different materials have different requirements).

After Sales Service

Related Keywords