Automatic Special Shaped Rolling Cutting Machine

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 100pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8451500000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

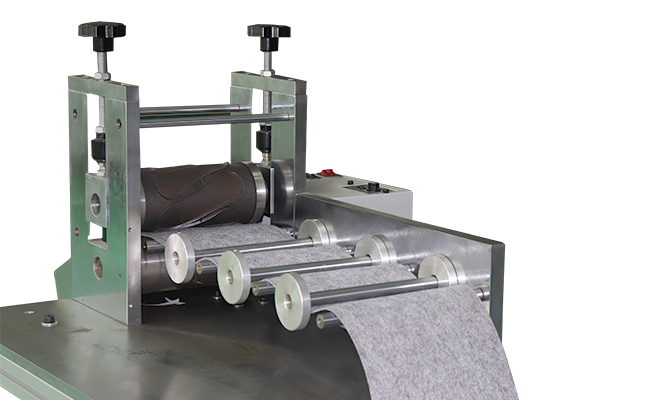

Automatic Special Shaped Rolling Cutting Machine

Flying Man automatic special shaped rolling cutting machine adopts the rolling die cutting method to cut, adding a round knife mold can die cut various shapes.

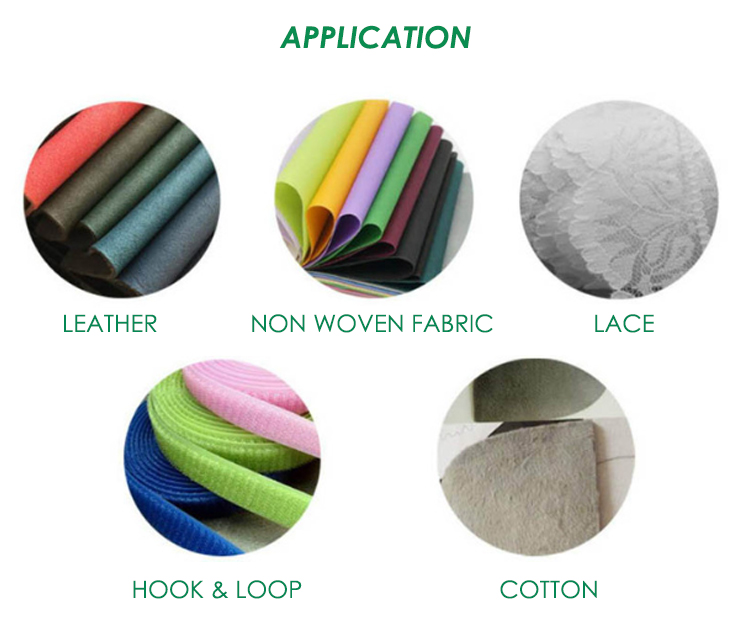

Roll Cutting Machine is suitable for cutting, embossing and compounding of chemical fiber fabric, human leather products and sprayed cotton, non-woven fabric, leather, plastic, paper and other materials.

High precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation, saving a lot of manpower and material resources.

|

Automatic Shape Roll Cutting Machine

|

|

|

|

|||

|

Model

|

FM-180

|

|

||||

|

Cutting thickness

|

0.5-3 mm

|

|

||||

|

Cutting width

|

maximum 170 mm

|

|

||||

|

Cutting speed

|

0-55 m/minute

|

|

||||

|

Power

|

130 w

|

|

||||

|

Voltage

|

220v 50

|

|

|

|||

|

Machine Weight

|

105 kgs (Gross weight: 175 kgs)

|

|

|

|||

|

Machine size

|

870 x 860 x 1330 mm

|

|

|

|||

ADVANTAGE

- Great productivity

The roller knife mold cutting method ensures high productivity and stable cutting performance.

- Cut out same size

The rolling cutting machine make sure the cutting shapes are cut out in same sizes, and it's easy to take off the cut products from the cutting material.

- Cut out different shapes, custom knife mold design

With the roller cutting technology, the machine is able to cut out different shapes from different material. Accept custom design the mold.

- Easy to operate

The control board are simplified ,the settings can be done easily.

DETAILS

Manual Screw adjustment & Aligment feeding fixtures

--- The roller knife cutting pressure can be adjusted by the screw, the screw can adjust the two roller distance and thus control the rolling cutting pressure, also the screw can be taken off for changing new roller knife molds.

--- The alignment feeding fixture will keep the cutting material away from swaying and cocky, it will lead cutting material straightforward and avoid distorted shape cutting. Ensure a perfect shape is cut out from this roller cutting machine.

Molds can be customized: triangle, serrated, wavy, dovetail, bevel, round, semicircle, chamfer and other special-shaped.

Technical Service

Training service

After Sales Service

Related Keywords