Ultrasonic cutting machine for V shape/round shape

-

$3200.001-5 Piece/Pieces

-

$3800.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 50pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| Certificate: | CE |

| HS Code: | 8456200000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Automatic Ultrasonic V Shape Cutting Machine for Webbing/Ribbon/Belt

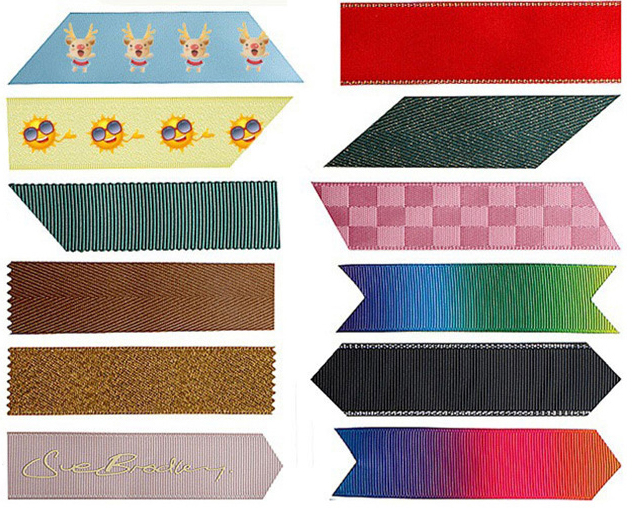

Flying Man automatic ultrasonic V shape cutting machine adopts ultrasonic cutting, the cutting edge is neat and smooth, no burr, no loose edge, no black edge, good cutting effect. This automatic V shape cutting machine can be used for cutting silk ribbon, webbing, Velcro, ribbon, non-woven fabric and other materials.

Feature

- Multi functional: Cutting, embossing, punching, welding.

- Fast speed: High speed can produce 200, 000/day.

- Various functions: Fixed length, fixed quantity, fixed speed, single/double knife can be cut.

- Easy operation: LCD screen, user-friendly operation interface, one button start/stop.

The cutting surface is flat without burrs, no black edges, neat and smooth.

Advantage

- Using ultrasonic cutting, the cutting edge is neat and smooth, no burr, no loose edge, no black edge, good cutting effect.

- Adopt PLC control, automatic feeding, computer counting, high precision, fast speed, free length adjustment, can be cut several pcs at the same time.

- Imported ultrasonic assembled, strong power, stable equipment performance.

Product Parameter

Automatic Ultrasonic Belt Cutting Machine

Model

FMUF-10018

FMUF-10020

Cutting Width

1-95 mm

Feeding speed

110 pcs/minutes (for 50mm length)

110 pcs/minutes (for 50mm length)

Ultrasonic Frequency

18KHZ

20KHZ

Voltage

220V/50-60HZ

Power

1.60 kw

2.10 kw

Machine Weight

95 kgs

125 kgs

Machine size

950 x 600 x 1250 mm

920 x 720 x 1250 mm

Product Details

A. PLC control system: set up automatic feeding, computer counting, high precision, fast speed, simple and efficient length adjustment.

B. Titanium alloy feeding wheel, no skid, feeding precision, wear-resistant.

C. Rotary ultrasonic tool head.

D. The air pressure intensity is 0.2-0.3 MPa.

Product Application

Training service

After Sales Service

A: We are a factory and manufacturer.

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Your question will be highly appreciated.

Related Keywords