Automatic Ultrasonic V Shape Cutting Machine

-

$3200.001-5 Piece/Pieces

-

$3800.00≥6 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 50pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| Certificate: | CE |

| HS Code: | 8456200000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Automatic Ultrasonic V Shape Cutting Machine for Webbing/Ribbon/Belt

Flying Man automatic ultrasonic V shape cutting machine adopts ultrasonic cutting, the cutting edge is neat and smooth, no burr, no loose edge, no black edge, good cutting effect. This auto ultrasonic cutter can be used for cutting silk ribbon, webbing, Velcro, ribbon, non-woven fabric and other materials.

Feature

- Multi functional: Cutting, embossing, punching, welding.

- Fast speed: High speed can produce 200, 000/day.

- Various functions: Fixed length, fixed quantity, fixed speed, single/double knife can be cut.

- Easy operation: LCD screen, user-friendly operation interface, one button start/stop.

The cutting surface is flat without burrs, no black edges, neat and smooth.

Advantage

- Using ultrasonic cutting, the cutting edge is neat and smooth, no burr, no loose edge, no black edge, good cutting effect.

- Adopt PLC control, automatic feeding, computer counting, high precision, fast speed, free length adjustment, can be cut several pcs at the same time.

- Imported ultrasonic assembled, strong power, stable equipment performance.

Product Parameter

Automatic Ultrasonic Belt Cutting Machine

Model

FMUF-10018

FMUF-10020

Cutting Width

1-95 mm

Feeding speed

110 pcs/minutes (for 50mm length)

110 pcs/minutes (for 50mm length)

Ultrasonic Frequency

18KHZ

20KHZ

Voltage

220V/50-60HZ

Power

1.60 kw

2.10 kw

Machine Weight

95 kgs

125 kgs

Machine size

950 x 600 x 1250 mm

920 x 720 x 1250 mm

Product Details

A. PLC control system: set up automatic feeding, computer counting, high precision, fast speed, simple and efficient length adjustment.

B. Titanium alloy feeding wheel, no skid, feeding precision, wear-resistant.

C. Rotary ultrasonic tool head.

D. The air pressure intensity is 0.2-0.3 MPa.

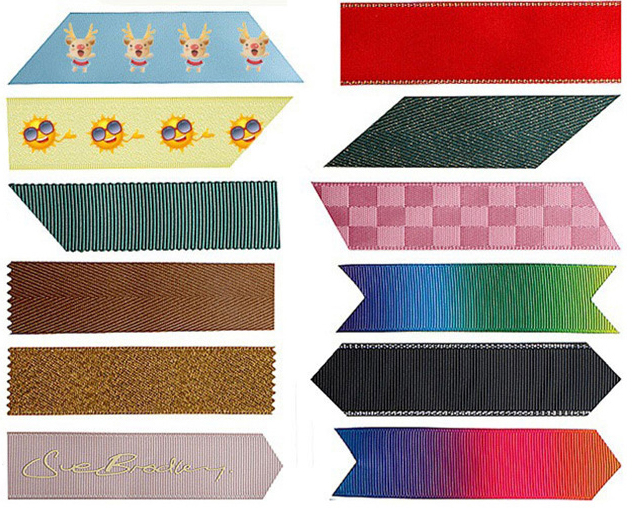

Product Application

Training service

After Sales Service

A: We are a factory and manufacturer.

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Your question will be highly appreciated.

Related Keywords