Automatic Electrical PVC Tape Roll Cutting Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50pcs/month |

| Supply Ability: | 50pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW |

| HS Code: | 8479899990 |

| Transportation: | Ocean,Land |

| Port: | Main port, China |

High Speed Automatic Electrical PVC Tape Roll Cutting Machine

Feature

- Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

- Independent development of special coil cutting machine motion control system, the core technology, and suitable for various industries equipment fixed length coil cutting.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- The cutter Angle is automatically adjusted.

- Set automatic grouping and total counting.

Product Parameters

Model

FMHZ-F250

Machine shaft width

1300 mm

Cutting precision

±0.1mm

Max cutting O.D.

250 mm

Cutting core O.D.

1'' - 3''

Min cutting width

1 mm

Diameter of circular blade

φ300mm

Voltage

380 v /50 hz

Power Supply

4.5 kw

Machine

weight

Around 750 kgs

Machine

Size

2300

x 1100 x 1300mm

Product Application

FMHZ-F250 Fully automatic roll to roll cutting machine can be used for slitting all kinds of roll tape and part of non-adhesive materials, such as BOPP tape, double-sided tape, rubber, PVC tape, PET tape, duct tape, foam tape, 3M tape series, polyester film tape, golden finger, MALa tape, PE protective film, copper foil, aluminum foil, non-woven fabric, release paper, etc.

This automatic roll cutting machine is widely used in electronics industry, automobile and motorcycle parts industry, clothing and leather industry, electrical appliances, motors, toys, transformers and other industries (different materials have different requirements).

Technical Service

Training service

After Sales Service

PACKAGE

SHIPPING

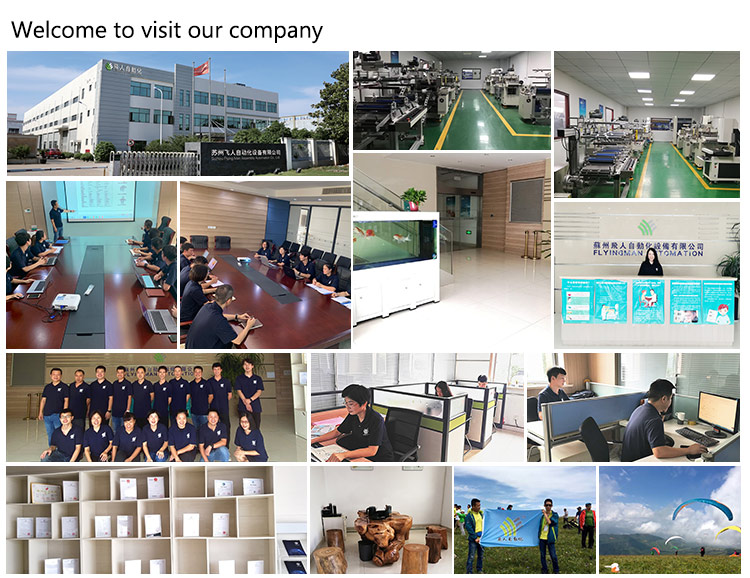

Q: Are you a factory or trading company?

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Related Keywords