Thermal paper cutting machine tissue paper cutter

-

$8900.001-5 Set/Sets

-

$8700.00≥6 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Main port, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50 sets/month |

| Supply Ability: | 50sets/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW,DAF |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Main port, China |

Flying Man tissue paper cutting machine adopts microcomputer numerical control display device, cutting length/quantity, feeding speed is set freely, add adjustable roller feeding mechanism, both sides automatically adjust the pressure and rise, can quickly release material, and prevent material damage effectively with thimble type feeding mechanism.

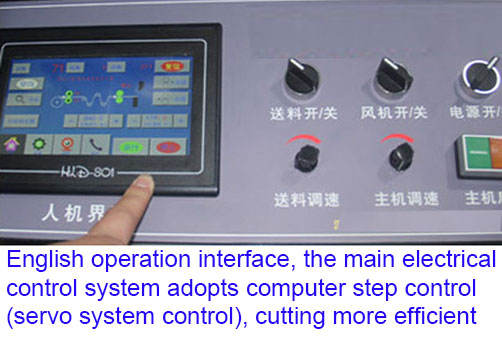

This roll to sheet cutting machine is suitable for transverse cutting of roll materials. This main electrical control system adopts computer stepping control, man-machine interface operation, dynamic display; The fixed length control is controlled by imported stepping motor system to ensure the cutting precision. This machine has advanced control mode. The speed of the main machine, imported stepper

motor and feeding motor is controlled by the computer centrally to achieve synchronous operation.

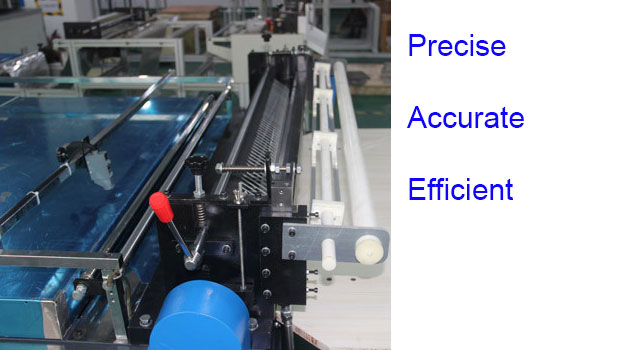

This paper cutter has the advantages of high cutting precision, fast speed, convenient feeding and neat stacking.

High precision, low loss, model design in line with the principle of ergonomics, simple operation and high automation.

This roll to sheeter machine is simple and practical, saving a lot of manpower and material resources.

|

Fully automatic roll to sheet cross cutting machine

|

|

|

|

|

|

|||||

|

Model

|

FMHZ-1000

|

|

||||||||

|

Cutting length

|

5 mm-5000 mm

|

|

|

|

|

|||||

|

Cutting Width

|

0 - 910 mm

|

|

|

|||||||

|

Cutting precision

|

±0.2 mm

|

|

|

|

|

|||||

|

Feeding diameter

|

1000 mm

|

|

|

|

|

|||||

|

Cutting speed

|

5-70 m/minute

|

|

|

|

|

|||||

|

Cutting thickness

|

0.05-0.6 mm

|

|

|

|

|

|||||

|

Cutting time

|

25-160 times/minute

|

|

|

|

|

|||||

|

Power

|

4.0 kw

|

|

|

|||||||

|

Voltage

|

220 v/50 HZ

|

|

|

|

|

|||||

|

Machine Weight

|

700 kgs

|

|

|

|||||||

|

Machine size

|

3320 x 1640 x 1270 mm

|

|

|

|||||||

Advantages & Features

regulation and length, automatic counting, sound and light alarm, swing arm straightening and other functions.

- Stepper motor control length, high precision.

- Stepper motor direct braking and high stop.

- Automatic counting, countdown stop, automatic program high.

- Special mechanical structure and special cutting tools, with professional software control to completely solve the problem of uneven incision and achieve the incision level/degree of accuracy.

- Independent development of the special cutting machine motion control system is the core technology, which is suitable for all industries equipment fixed-length cutting.

- Large screen LCD display, easy to operate, simple and convenient.

- High speed feeding, under microcomputer program control, material's accuracy can be up to 0.1mm.

- The length and speed can be adjusted continuously to achieve high efficiency.

- Cutter speed can be adjustable, high and low speed of cutting machine can be fully controlled.

- Set up automatic group accumulator and total accumulator count.

- Batch pause and delay time can be set.

Machine configuration.

- Stepping motor (1 pc)

- Blade (1 set)

- electrostatic treater (1 set)

- Rear feeding motor (1 pc)

- Receiving material platform (1 pc)

- Blow motor (1 pc)

- Frequency converter (1 pc)

Imported high quality SK-11 fine steel cutting knife, to ensure that the incision is smoother, no burr! (we can be customized

according to customer requirement, cutting width from 800mm to 2000mm)

and etc.

It is widely used in electronics industry, automobile and motorcycle parts industry, clothing and leather industry, electrical appliances, motors, toys, transformers and other industries (different materials have different requirements).

Technical Service

Training service

After Sales Service

Related Keywords