Electronic Materials Asynchronous Die Cutting Machine

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai port, China, Ningbo port, China

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 20 pcs/month |

| Supply Ability: | 20 pcs/month |

| Payment Type: | L/C,T/T,Negotiation |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE certification |

| HS Code: | 8441100000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai port, China,Ningbo port, China |

Product Description

Product Description

Electronic Materials Asynchronous die cutting machine

Electronic Materials asynchronous die cutting machine has a higher utilization rate of raw materials, time-saving and efficient superior performance relative to the traditional die cutting machine.

Industry Highest Performance Characteristics

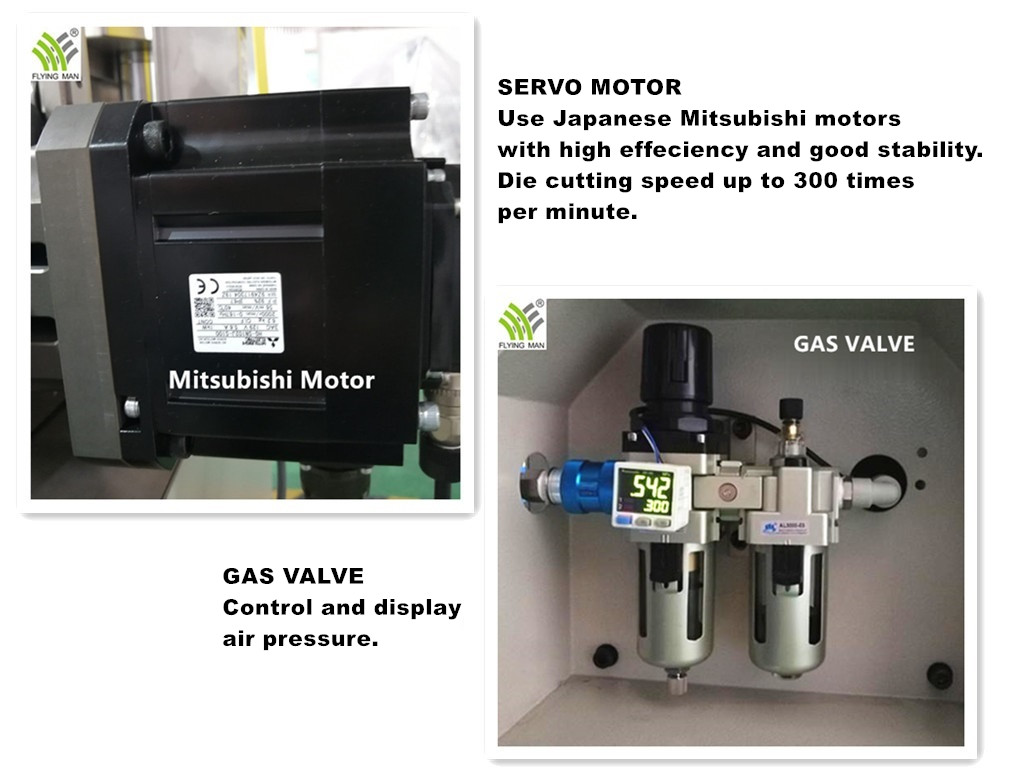

- Professional equipment for die cutting process, high precision, reliable, safe and durable. - Lifting roller type hole positioning system.

- High flatness of pressure, no adjustment for kiss cutting.

- Pressure regulating by touch screen, punching depth up 0.003 mm.

- 2 times punching pressure than the same type of equipment in the industry.

- Woodcut knife, plastic-cut knife, graver, etching knife, hardware mold and sectional die are all suitable.

- Human computer-interface easy to operate, keep safety and effectiveness in maximum level.

- Auto oil control system, testing high and loop of oil all the time.

Product Parameters

|

SPECIFICATIONS FOR HIGH SPEED PRECISION ASYNCHRONOUS DIE CUTTING MACHINE

|

|

|

|

Model

|

ENZO-350YB

|

|

|

Max. Die Cutting Speed

|

300 times/min

|

|

|

Asynchronous max. speed

|

130 times/min

|

|

|

Max. Feeding Width

|

350 mm

|

|

|

Max. Winding Width

|

300 mm

|

|

|

Material thickness

|

0.025-2.0 mm

|

|

|

Total Power

|

7.5 kw

|

|

|

Voltage

|

AC 380 v

|

|

|

Air Pressure

|

0.5 Mpa

|

|

|

Machine Sizes (L*W*H)

|

2400 x 1200 x 1800 mm

|

|

|

Total Weight

|

2300 kg

|

|

|

Mold type

|

Woodcut knife, plastic-cut knife, graver, etching knife, hardware mold and sectional die

|

|

|

Minimum joint seam for PET products

|

0.03 mm

|

|

|

Minimum joint seam for foam products

|

0.1 mm

|

|

|

Die cutting precision

|

± 0.03 mm

|

|

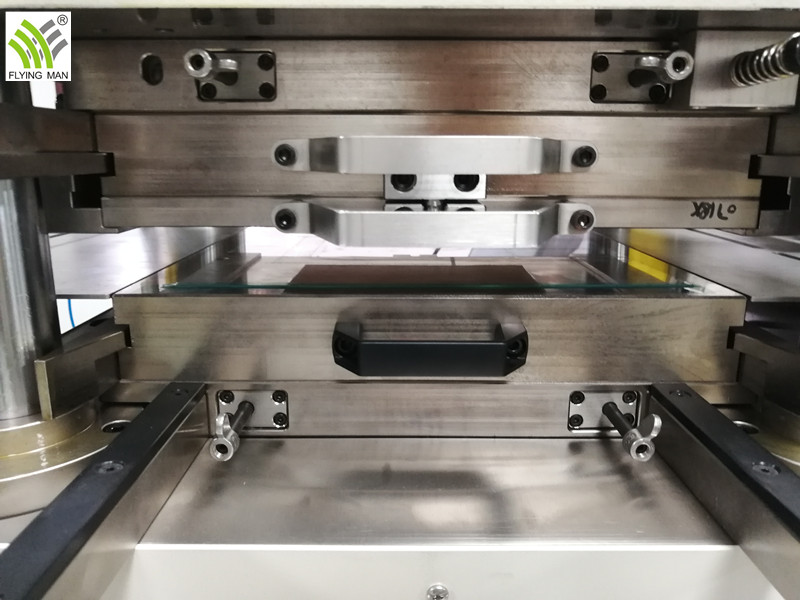

Die cutting station

This unit is used to die cut material, you can install the die from here. When material passed, it pouch and die cut the products.

The speed is adjustable, the deepth and force is adjustable too.

Touch screen

You can set all parameter in touch screen, the length batch quantity ,total quantity, die cutting speed, etc. It's convenient for workers to operate.

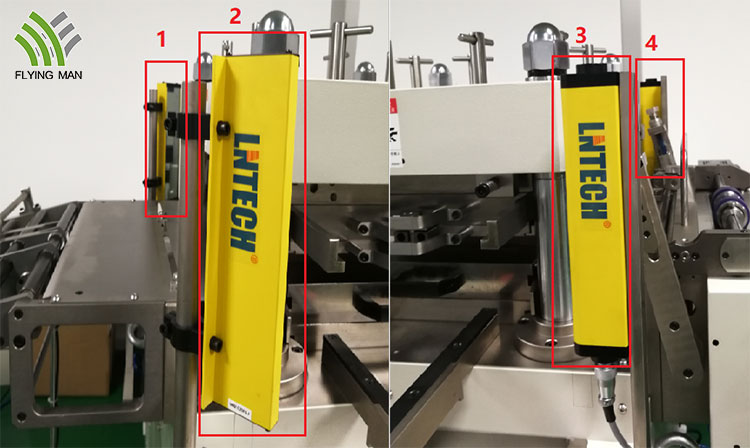

Safety protection

There are four electronic protection light curtains around the machine. Once there is anything materials, such as the operator's hand enters the sensing range, the machine will stop working immediately.

Product Application

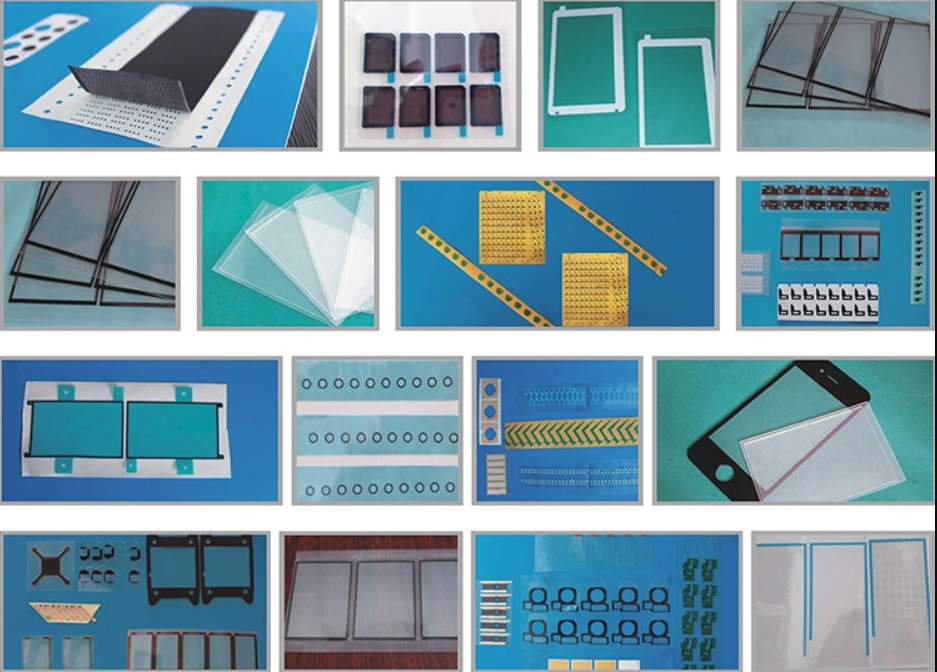

Flying Man precision die cutting machine is suitable to die cut thin flexible electrically insulating materials such as plastic films, rubber, fibers, and papers. These materials are widely applied many industries including Electronic devices, Servers and personal computers, Power supplies, transformers, inverters, Battery / electronic vehicle, Lighting assemblies, Aerospace systems, Military / Defense, Automotive electronics, Medical devices and etc.

Technical Service

- Free sample testing and video for your reference.

- Technical support: Professional engineers’ team to help you design a whole-set product line to get highest profit with lowest cost and offer you technical support any time.

Training service

Free training in our factory available before delivering machines. Engineers available to service machinery overseas. Overseas service center in Vietnam available.

After Sales Service

- Every customer can get one piece of English operation manual , a total working video for machines ,details on every button function ,normal notice when operation. - One-year warranty, whole life technical support.

- 24 hours technical support, we will do our best to help our customers solve problems.

- We offer not only the products, but also the solutions. Plenty of cooperated professional supplier for mold or other necessary equipment make it possible for us to offer our customers big convenience to complete their production line in high quality with low cost in a short time.

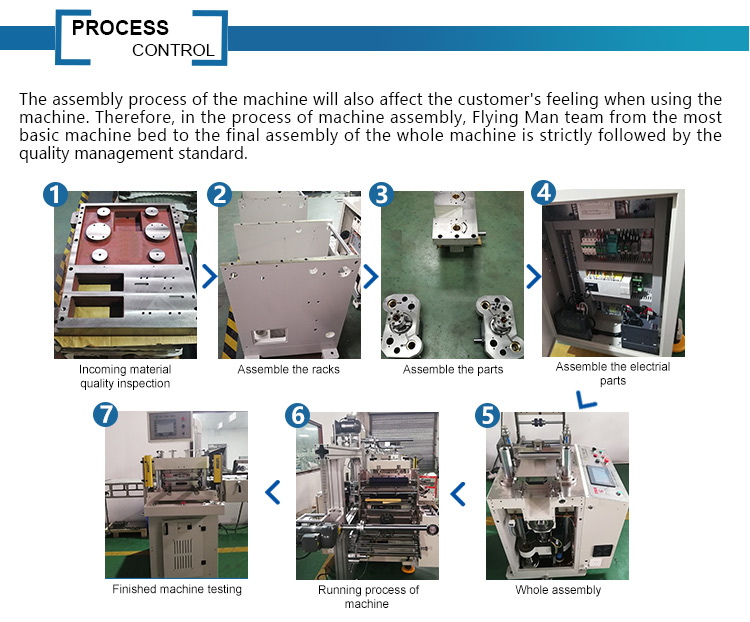

process control

PACKAGE

We use exporting standard packing. First to wrap PE film around the machine, then packed by plywood case to ensure the package enough safe and strong. It’s easy for forklift to upload and download and safety transportation. We also can pack the machine according to customers special requirement.

SHIPPING

Usually we suggest customers choose ocean shipping to ship machinery, or air transport for small machine or urgent order. We also supply shipping service with our cooperation shipping forwarder to help customers to deliver the machinery in first time.

Related Keywords

Related Keywords