Tr 4x1 Leadscrew Diameter 4mm Lead 1mm

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou |

|---|---|

| Productivity: | 20000/month |

| Supply Ability: | 20000/MONTH |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHANGHAI |

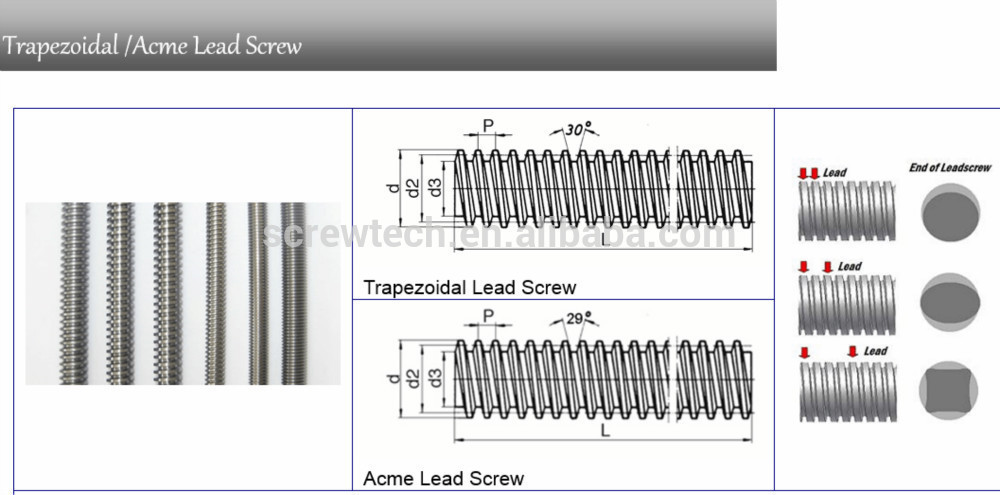

4mm trapezoidal lead screw for Tr4*1

Parts Processing

The part is a screw wheel with adjustable spanner to adjust the opening width, the material is 20 gauge round steel, the tooth side has a certain roughness requirement, the thread part of the cutting part needs to be chamfered, and the middle pin hole and the outer cylindrical surface must have good coaxiality , Otherwise it will not be flexible or even stuck during adjustment. In order to facilitate the thumb to hold and move, the surface should have straight knurled parallel to the axis line.

Processing skills

The screw processing originally used turning processing. The process route is: cold drawing→knurling→threading→correction→drilling→cutting→chamfering, which is not only low in efficiency and high in cost, but also due to the low rigidity of small round steel, turning and knurling It is easy to deform and the small screw wheel cannot be produced. For this reason, we designed a whirlwind milling screw equipment, which not only increases the speed from about 1000r/min as determined by experience to more than 2000r/min, but also completes the milling knurling at one time. The process route becomes: cold drawing→knurling, wire milling→correction→drilling, cutting→chamfering. Although whirlwind milling makes small-diameter workpieces have greater deformation (large-diameter parts have less deformation), correction is also easy. The improved process has the following characteristics:

The surface roughness value decreases;

Reduced vibration caused by cutting force;

The cumulative error of the pitch of small diameter workpieces has a certain increase.

Our advantage

We are the professional manufacturer in China for precision ball screw,precision mini ball screw,precision lead screw with more than 15 years experience!We accept customized products!Welcome send us your drawings to design your target products!

If there have more demands, please contact with us.