24mm lead screw with trapezoidal thread for Tr24x3

-

$90.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

24mm lead screw with trapezoidal thread for Tr24x3

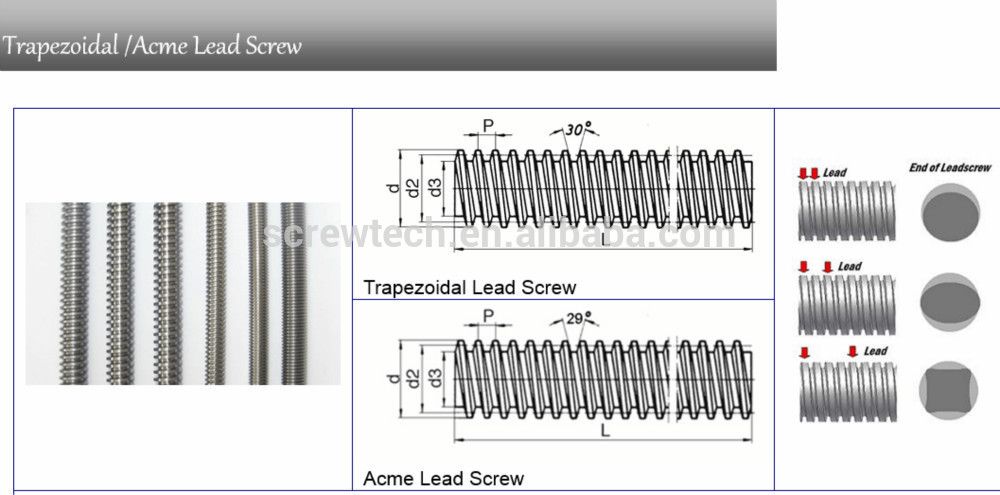

In whirlwind milling screw processing, the thread and knurling can be completed at one time. The product has high process efficiency, low cost, and low machining accuracy requirements. Its structural design ideas and schemes have good promotion and application value.

The screw processing originally used turning processing. The process route is: cold drawing→knurling→threading→correction→drilling→cutting→chamfering, which is not only low in efficiency and high in cost, but also due to the low rigidity of small round steel, turning and knurling It is easy to deform and the small screw wheel cannot be produced. For this reason, we designed a whirlwind milling screw equipment, which not only increases the speed from about 1000r/min recognized by experience to more than 2000r/min, but also completes the milling knurling at one time. The process route becomes: cold drawing→knurling, wire milling→correction→drilling, cutting→chamfering. Although whirlwind milling makes small-diameter workpieces have greater deformation (large-diameter parts have less deformation), correction is also easy. The improved process has the following characteristics:

The surface roughness value decreases;

Reduced vibration caused by cutting force;

The cumulative error of the pitch of small diameter workpieces has a certain increase.

Our advantage

We are the professional manufacturer of lead screw and ball screw in China for precision ball screw,precision mini ball screw,precision lead screw with more than 15 years experience! We accept customized products! Welcome send us your drawings to design your target products!

Our lead screw feature

1. Fast delivery from 5 days to 30 days at most 2. Durable and reliable

3. High positional accuracy 4. Low friction

5. Good synchronism 6.Long service life

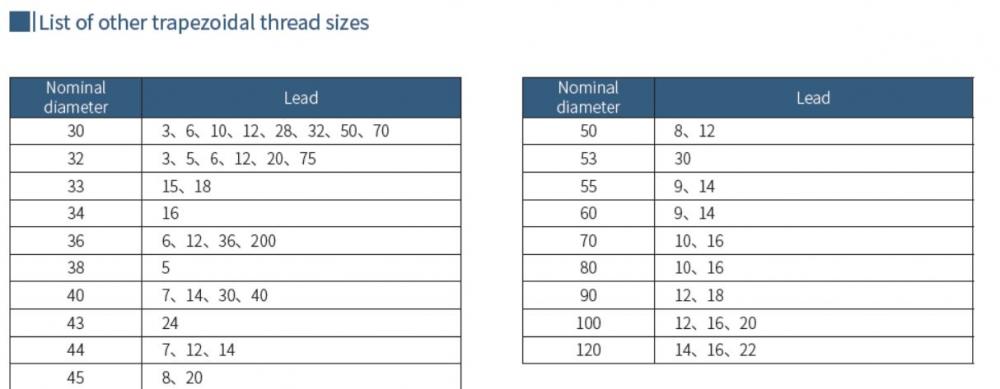

Application

Automatic controlling machines, cnc machine, cnc lathe, semi-conductor industry, general industrial machinery, machine tools, medical equipments, parking systems, measuring instrument, printing machine, stepper motor, ect,,

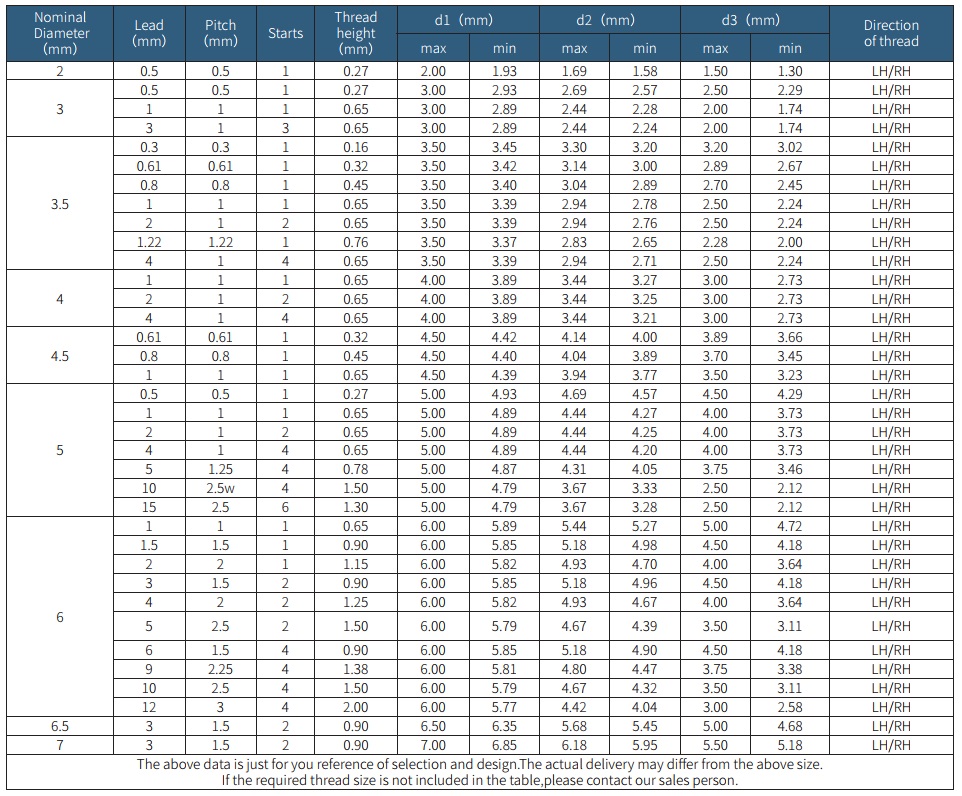

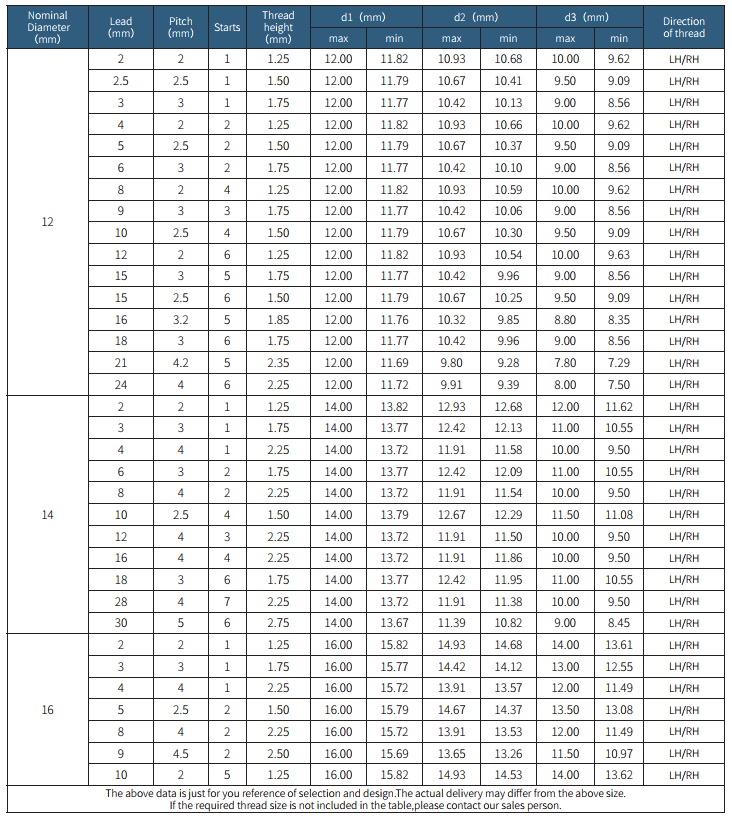

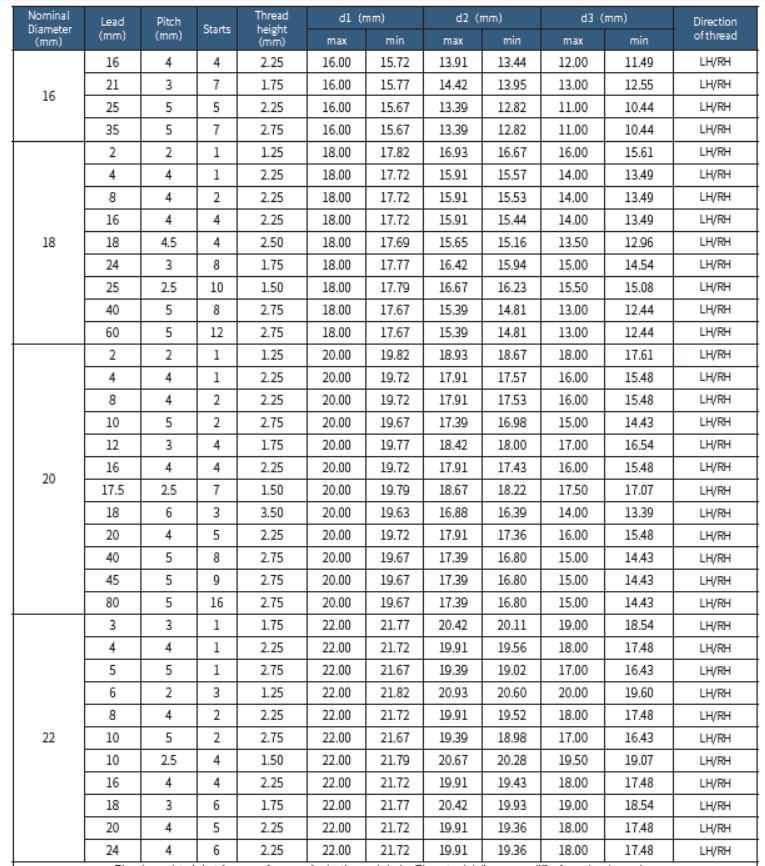

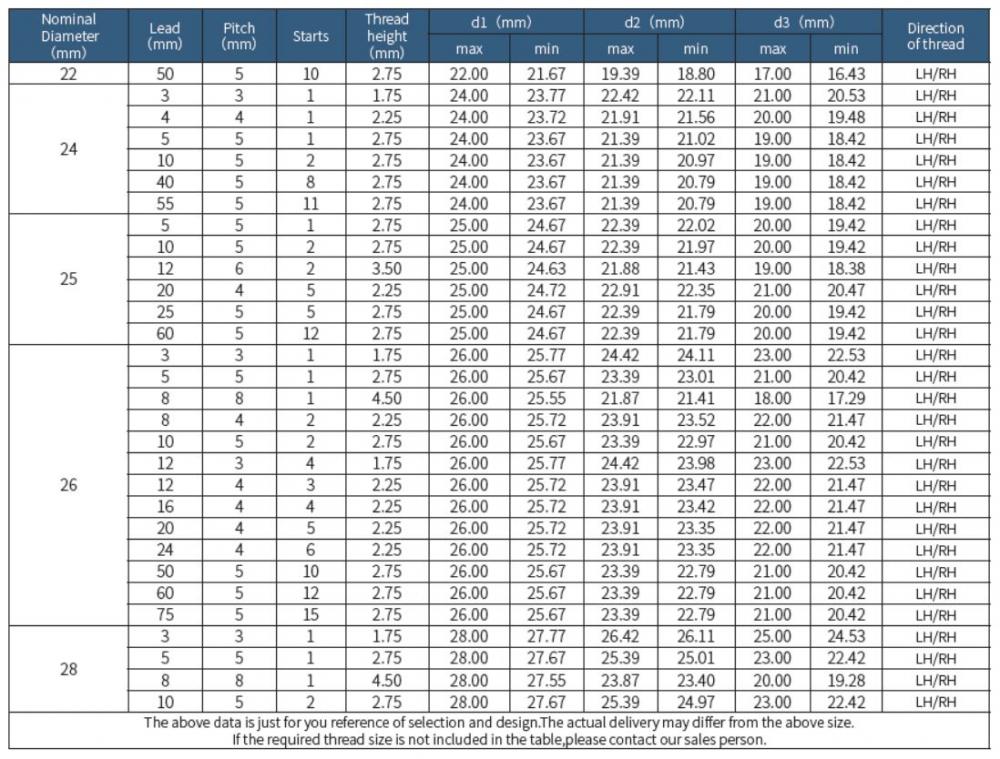

More detail for lead screw

1. Material: 1045 Carbon Steel, SUS303, SUS304 or others.

2. 2 starts, 3 starts, 4 starts and more are all available.

3. Major diameter: 2mm-200mm, Lead: 1mm-22mm.

4. Max length: 6 meters.

5. Left hand thread is available upon request.

6. A-c-m-e thread, square metric and other non-standard thread profiles are available upon drawings.

7. Higher Precision Grade is available upon request.

Our product series

Our factory Photos

Why choose us ?

1.Our products are various and accept CUSTOMIZED UPON RECEIVING YOUR DRAWINGS

2.We provide the best service for you!

1) We have a group of professional engineers we can provide drawings according to customer's requirements.

2). We have more than 20 machines for offering professional lead screw and ball screw end machining service.

3). We can rebuild, refurbish, and make emergency repairs tolead screw, ball screw and linear guideways.

4). We can disassemble, clean, polish lead screw, linear guideways and lead screw, ball screw

5). Two years free maintenance to lead screw , ball screw and one years free maintenance to linear guideways.

3.Above all, we offer the competive price,we are the original manufacturer.we process by ourselves and sell directly.We keep in touch with our factory during 24H online and by phone.so we can save much intermediate cost and give the best price to you as well as the fast delivery and swift problem solving!!

Related Keywords