C5 precision SFU2505 ball screw

-

$19.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Air, Express, Land

- Port:

- ShangHai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,Express Delivery,CFR,CIF,DAF,EXW,FAS |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Air,Express,Land |

| Port: | ShangHai |

Professional manufacturer of ball screws for more than 10 years!

Ball screw is an ideal product that converts rotary motion into linear motion, or converts linear motion into rotary motion.

Ball screw is the most commonly used transmission element in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion, or convert torque into axial repetitive force. At the same time, it has both high precision, reversibility and high Features of efficiency. Because of its low frictional resistance, ball screws are widely used in various industrial equipment and precision instruments.

The ball screw is composed of a screw, a nut, a steel ball, a pre-compression piece, a reverser, and a dustproof device. Its function is to convert rotary motion into linear motion, which is a further extension and development of Akem screw. The important significance of this development is to change the bearing from sliding motion to rolling motion.

Our advantage:

◊Steady Exporting to Europe, Northern America, Asia, Southeast Asia.

◊Processing four distributors in domestic:

SHENZHEN, SHANDONG, TIANJIN, SHANGHAI

Supplying 3000~4000 sets to these distributors monthly.

◊Fast delivery:10~15 days for standard models.Customized items: 30 days around.

◊Competitive price: We are factory that can export directly to customer. so there is no intermediary cost involved.&Price is much cheaper than other brand.

◊Customized service:Full types are available upon request.

Our Ball Screw Key Features

1. High mechanical efficiency

2. Low noise

3. Accuracy grade of C3, C5

4. Long service life

5. Good synchronism

6. Reliable quality

Specification for ball screw 2505

| Product name | Ball Screw |

| Model | GQ2505 |

| Diameter | 25mm |

| Lead(Pitch) | 5mm |

| Thread length | 510 mm |

| Shaft length | 620 mm |

| Thread | Right hand |

| Material | GCR15 |

| Production Technology | By grinding |

| Feature | High reliable and high quality C5 |

| Notes:Left hand, right hand, right and left hand all available(click to view more) | |

The standard model for bi-directional ball screw in stock

Note: Other sizes,and nut shapes are available upon request !!

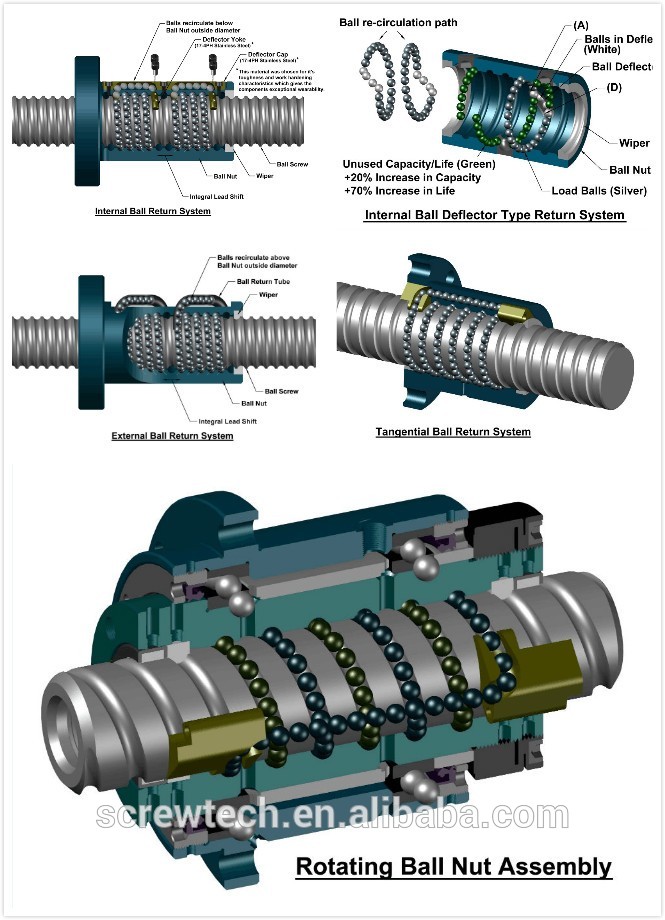

The characteristic of ball-screw pair

The ball screw drive system is a rolling screw drive system, in which the ball acts as the rolling medium. There are two drive modes:

(1) transform rotary motion into linear motion. (2) transform linear motion into rotary motion.

Ball Screw Features

1. High transfer efficiency

Balls with free motion in the ball screw assembly transfer the force and motion between screw and nut. This transfer mode replaces the traditional transfer mode that screw shaft and nut effect directly. Therefore the minimum rolling friction takes place of the sliding friction of traditional screw. The transfer efficiency of ball screw will reach more than 90%. The drive torque of transfer unit reduces to 1/3 of sliding screw. This also reduces the heat release largely.

2. High positioning accuracy

Ball screw has low heat release, small temperature increase and with actions of pre-stretch and eliminating axial clearance in the process, which make ball screw have high positioning accuracy and repeating positioning accuracy.

3. Reversibility

Ball screw has not sticky friction like sliding screw. It clears crawl which may exists during transfer. Ball screw can achieve two transfer modes - from rotary motion to linear motion and from linear motion to rotary motion, and transfer momentum.

4. Long service life

Since the strict control of ball screw groove shapes, surface hardness and material selection, the actual life of ball screw is much longer than sliding screw.

5. Good synchronization

Due to smooth running, axial clearance elimination and consistency in manufacture, several sets of ball screw assembly can drive the same unit or several identical parts to obtain the good synchronization

Ball Screw circulation mode

Application fields

Automatic controlling machines, semi-conductor industry, general industrial machinery, machine tools, medical equipments, parking systems, measuring instrument, Automatic computer strip machine, Gantry cranes, Gantry robot, 3D engraving machine, linear stage, electric tools, linear actuator ect..

Our Ball Screw series

1.Miniature ball screw

2.Left hand ball screw

3.Bi-directional ball screw

4.Stainless steel ball screw

5.Customized ball screw

1.Specification of M-ISNF series( standard model, fast delivery 7-15 days)

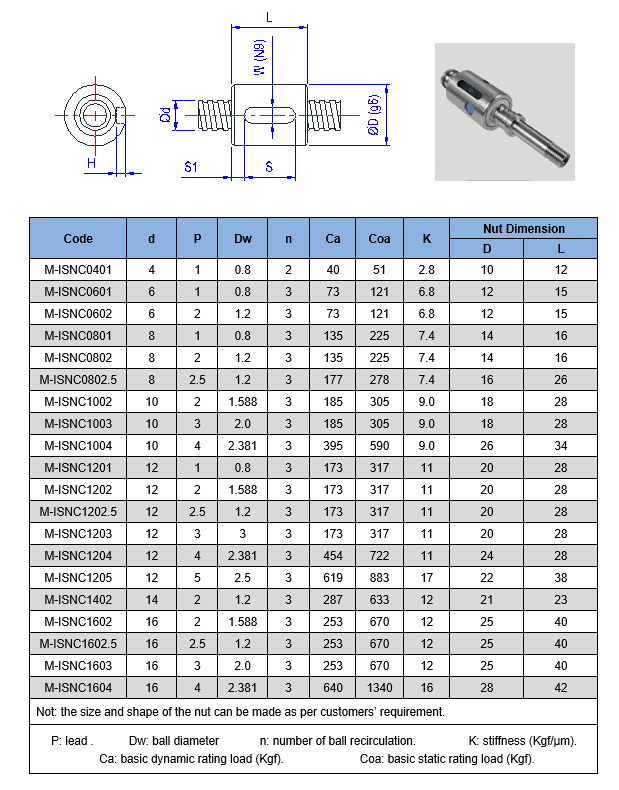

3.Specification of M-ISNC series

Other types and shapes are available upon request

Our ball screw range:

Miniature Dia. : Ø 4 ~ 16 mm

Some unique models such as 0401, 0602 , 1210,1404 and so on.

Nominal Diameter: Ø 16~ 300 mm

Nut type: Standard or customized.

Customized item, lead time: 30 days at most

Processing technology:by grinding

Accuracy grade:C3 C5 C7

Thread Direction : Right ; Left ; Bi-directional

Material: Gcr15 or stainless steel

You can use our own brand or we design and produce customized products as per your requirement.

Why choose us ?

1. The unique and professional manufacturer for ball screw in China

Screwtech designs, manufactures a large array of ball screws:

a.Standard ball screw:M-ISNF flange nut ball screw; M-ISNA,M-ISNC round nut without flange ball screw.

b.Customized ball screw,miniature ball screw, large diameter ball screw, high helix ball screw.

c.Ball screw thread direction: right hand, left hand, bi-directional thread ball screw.

d.Material:Gcr15, stainless steel

e:Surface coating:black oxide, T/e/f/l/o/n, PTFE etc..

2. Processing a number of distributors in China locally:

Shenzhen, Guangzhou, Shanghai ,Shandong, Tianjin

3 Quality control

1).We have QC department to control quality for each step.

2).We also have Automatic product equipments(German Chiron FZ15W ,DMG MORI MAX3000 Machining Centers ) which can cantrol the precision itself

3).ISO9001:2008

4 Competitive Price

Screw Technology is a manufacturer which can export directly to customer, so there is no intermediary cost involved.

5 Fast Delivery

Standard model: 7~15 days

Customized model: 30 days at most

6 Best After-Sale Service

After-sale service and any technical assistance are always given quick support within 12H.

Related Keywords