Large ball screw for linear motion system

-

$29.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- ShangHai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,Express Delivery,CFR,CIF,DAF,EXW,DES,FAS,FCA |

| Certificate: | IATF16949 |

| HS Code: | 8483409090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShangHai |

Ball screw 1616 for linear motion systems

There are two commonly used circulation methods: outer circulation and inner circulation. The ball is sometimes out of contact with the screw during the circulation process is called the outer loop; the ball is always in contact with the screw is called the inner loop. Each closed loop of the ball is called a row, and the number of leads contained in the closed loop of each ball is called the number of turns. There are 2 rows, 3 rows, 4 rows and 5 rows of each nut of the inner circulation ball screw pair, and each row has only one circle; each row of the outer circulation has 1.5 circles, 2.5 circles and 3.5 circles and so on.

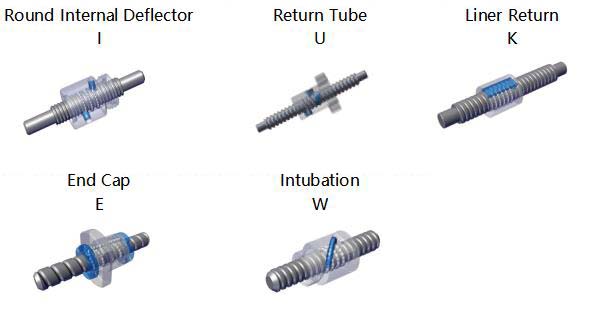

1) External circulation: The external circulation is that the balls re-enter the circulation through the spiral groove or cannula on the outer surface of the nut and return to the screw and nut after the end of the circulation process. The return methods of the external circulation ball screw nut pair according to the ball circulation mainly include end cap type, intubation type and spiral groove type. Commonly used external circulation methods are end cap type; intubation type; spiral groove type. For the end cover type, a longitudinal hole is machined on the nut as a return passage for the balls. The cover plates at both ends of the nut are provided with return openings for the balls, from which the balls enter the return pipe to form a circulation. Intubation type, which uses elbows as return pipes, this structure has good manufacturability, but because the pipes protrude from the outside of the nut, the radial size is large. Spiral groove type, which mills a spiral groove on the outer circle of the nut, and drills through holes at both ends of the groove and is tangent to the threaded raceway to form a return channel. This structure is smaller than the intubation structure in radial size, but Manufacturing is more complicated. The outer circulation ball screw has a simple structure and manufacturing process and is widely used. The disadvantage is that it is difficult to smooth the seam of the raceway, which affects the stability of the ball raceway.

2) Inner circulation: Inner circulation adopts reverser to realize ball circulation, and there are two types of reverser. Cylindrical convex key reverser, its cylindrical part is embedded in the nut, and a reverse groove 2 is opened at the end. The reverse groove is positioned by the cylindrical outer surface and the round key 1 on the upper end to ensure the alignment of the thread raceway direction. The oblate insert reverser, the reverser is a general round head flat key insert, the insert is embedded in the groove of the nut, and the end is provided with a reverse groove 3, which is positioned by the outer contour of the insert. Comparing the two reversers, the latter is smaller in size, thereby reducing the radial dimension of the nut and shortening the axial dimension. However, the dimensional accuracy of the outer contour of the reverser and the groove on the nut is relatively high.

Specification for ball screw 1616

| Product name | Ball Screw |

| Model | CSNF1616 |

| Diameter | 16mm |

| Lead(Pitch) | 16mm |

| Thread length | 510 mm |

| Shaft length | 620 mm |

| Thread | Right hand |

| Material | GCR15 |

| Production Technology | By grinding |

| Feature | High reliable and high speed |

| Notes:Left hand, right hand, right and left hand all available(click to view more) | |

The standard model for bi-directional ball screw in stock

Note: Other sizes,and nut shapes are available upon request !!

The characteristic of ball-screw pair

The ball screw drive system is a rolling screw drive system, in which the ball acts as the rolling medium. There are two drive modes:

(1) transform rotary motion into linear motion. (2) transform linear motion into rotary motion.

Ball Screw Features

1. High transfer efficiency

Balls with free motion in the ball screw assembly transfer the force and motion between screw and nut. This transfer mode replaces the traditional transfer mode that screw shaft and nut effect directly. Therefore the minimum rolling friction takes place of the sliding friction of traditional screw. The transfer efficiency of ball screw will reach more than 90%. The drive torque of transfer unit reduces to 1/3 of sliding screw. This also reduces the heat release largely.

2. High positioning accuracy

Ball screw has low heat release, small temperature increase and with actions of pre-stretch and eliminating axial clearance in the process, which make ball screw have high positioning accuracy and repeating positioning accuracy.

3. Reversibility

Ball screw has not sticky friction like sliding screw. It clears crawl which may exists during transfer. Ball screw can achieve two transfer modes - from rotary motion to linear motion and from linear motion to rotary motion, and transfer momentum.

4. Long service life

Since the strict control of ball screw groove shapes, surface hardness and material selection, the actual life of ball screw is much longer than sliding screw.

5. Good synchronization

Due to smooth running, axial clearance elimination and consistency in manufacture, several sets of ball screw assembly can drive the same unit or several identical parts to obtain the good synchronization

Ball Screw circulation mode

BALL SCREW SERIES

1.Specification of M-ISNF series( standard model, fast delivery 7-15 days)

2.Specification for M-ISNA series

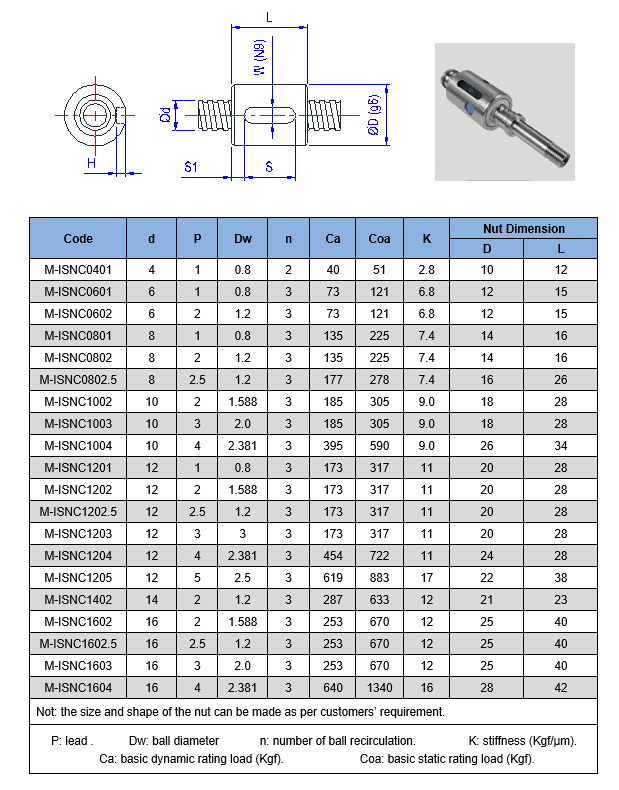

3.Specification of M-ISNC series

Other types and shapes are available upon request

Our ball screw series:

Miniature Dia. : Ø 4 ~ 16 mm

Some unique models such as 0401, 0602 , 1210,1404 and so on.

Nominal Diameter: Ø 4 ~ 32 mm

Nut type: Standard or customized.

Customized item, lead time: 30 days at most

Processing technology:by grinding

Accuracy grade:C3 C5

Thread Direction : Right ; Left ; Bi-directional

Material: Gcr15 or stainless steel

You can use our own brand or we design and produce customized products as per your requirement.

Why choose us ?

1. The unique and professional manufacturer for ball screw in China

Screwtech designs, manufactures a large array of ball screws:

a.Standard ball screw:M-ISNF flange nut ball screw; M-ISNA,M-ISNC round nut without flange ball screw.

b.Customized ball screw,miniature ball screw, large diameter ball screw, high helix ball screw.

c.Ball screw thread direction: right hand, left hand, bi-directional thread ball screw.

d.Material:Gcr15, stainless steel

e:Surface coating:black oxide, T/e/f/l/o/n, PTFE etc..

2. Processing a number of distributors in China locally:

Shenzhen, Guangzhou, Shanghai ,Shandong, Tianjin

3 Quality control

1).We have QC department to control quality for each step.

2).We also have Automatic product equipments(German Chiron FZ15W ,DMG MORI MAX3000 Machining Centers )

Related Keywords