Ball Screw 2005 diameter 2005mm

-

$67.00≥1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 10000/month |

| Supply Ability: | 10000 sets/year |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Outer circulation: The outer circulation means that the balls return to the screw nut through the spiral groove or intubation on the outer surface of the nut after the circulation process is over. The return methods of the outer circulation ball screw nut pair according to the ball circulation mainly include end cap type, intubation type and spiral groove type. Commonly used outer circulation method: end cap type; intubation type; spiral groove type. In the end cap type, a longitudinal hole is machined on the nut to serve as the return passage of the balls. The cover plates at both ends of the nut have return ports for the balls, and the balls enter the return pipe to form a cycle. Intubation type, it uses an elbow as the return pipe. This structure has good manufacturability, but because the pipe protrudes from the nut body, the radial dimension is relatively large. Spiral groove type, it is a spiral groove milled on the outer circle of the nut, through holes are drilled at both ends of the groove and tangent to the threaded raceway to form a return channel. This structure has a smaller radial size than the cannula structure, but Manufacturing is more complicated. The outer circulation structure and manufacturing process of the outer circulation ball screw are simple and widely used. The disadvantage is that it is difficult to smooth the joints of the raceways, which affects the stability of the ball raceways.

Inner circulation: Inner circulation adopts inverters to realize ball circulation. There are two types of inverters. Cylindrical convex key reverser, its cylindrical part is embedded in the nut, and the end is provided with a reverse groove 2. The reverse groove is positioned by the cylindrical outer surface and the round key 1 at the upper end to ensure the alignment of the thread raceway direction. Oblate insert reverser, the reverser is a general round head flat key insert, the insert is embedded in the slot of the nut, and the end is opened with a reverse groove 3, which is positioned by the outer contour of the insert. Comparing the two inverters, the latter has a smaller size, which reduces the radial size of the nut and shortens the axial size. However, the outer contour of this kind of reverser and the dimensional accuracy of the slot on the nut are required to be high.

|

Material

|

Stainless steel or GCr15 ; others available upon request

|

|

Dimension

|

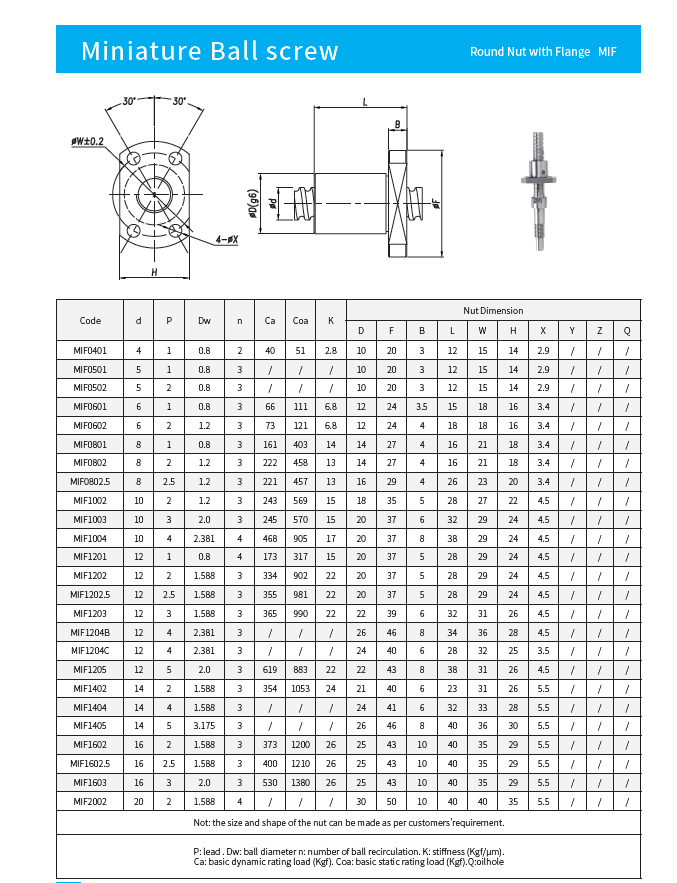

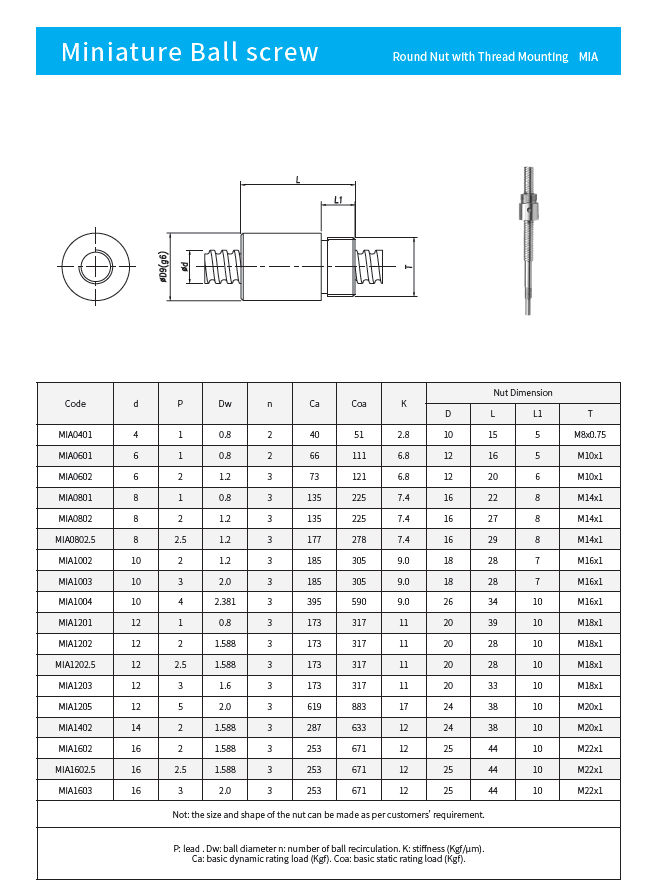

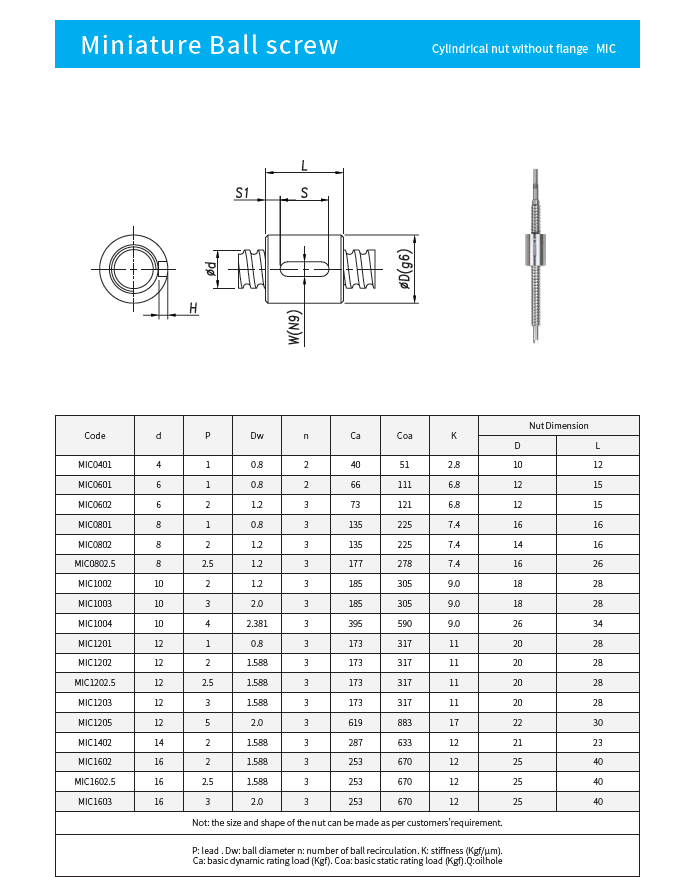

Norminal Diameter : from 4 to 32mm

|

|

Thread Direction

|

Right hand thread, left hand thread, bi-directional thread all available

|

|

Accuracy Grade

|

C3 C5 C7

|

|

Application

|

Automatic controlling machines, semi-conductor industry, general industrial machinery, machine tools, medical equipment, parking systems, measuring instrument, Automatic computer strip machine, Gantry cranes, Gantry robot, 3D engraving machine etc.

|

|

Remarks

|

Various ballnuts are available upon drawing

|

SFU double ballnut and custom ballnut ball screw

Custom flanged ballnut ball screws

1. We Screwtech is a professional manufacturer of Ball Screws,Lead Screws.Meanwhile, Distributing Stepper Motor,Linear Guideway,AKD-Support for ball screw,Coupling,Linear Module for more than 10 years.

2. As the unique and professional original factory,we can offer you products of high quality with competitive price and fast delivery.

3. Customized service:Various models are available upon request.

4.We can produce the same size as that from HIWIN, TBI, PMI, and THK.

Features of our mini ball screw

※ High mechanical efficiency

※ Zero Axial play

※ Accuracy grade of C3, C5, C7

※ Long service life

※ Smooth running

1.We have business relations with clients both domestic and abroad.

In domestic,our distributor mainly located in Guangdong province,Shandong province,Jiangsu province.

2.With the high quality,good service as well as reasonable price,

We've kept steady and large exporting to Europe, Northern America, Australia,Korea and so on.

Related Keywords