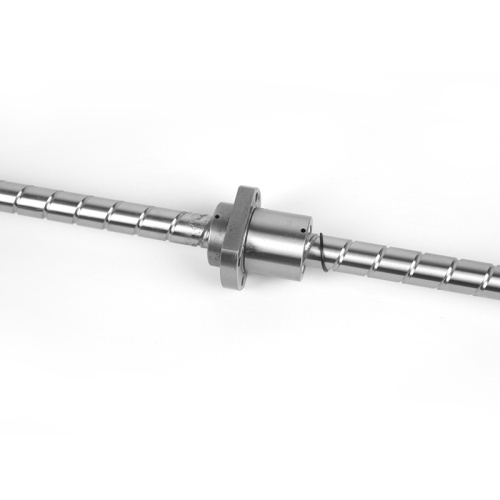

Double-Nut Ball Screw with High Precision

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou |

|---|---|

| Productivity: | 20000 pcs/ month |

| Supply Ability: | 20000 pcs/ month |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDU,DDP,Express Delivery,DAF,DES |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

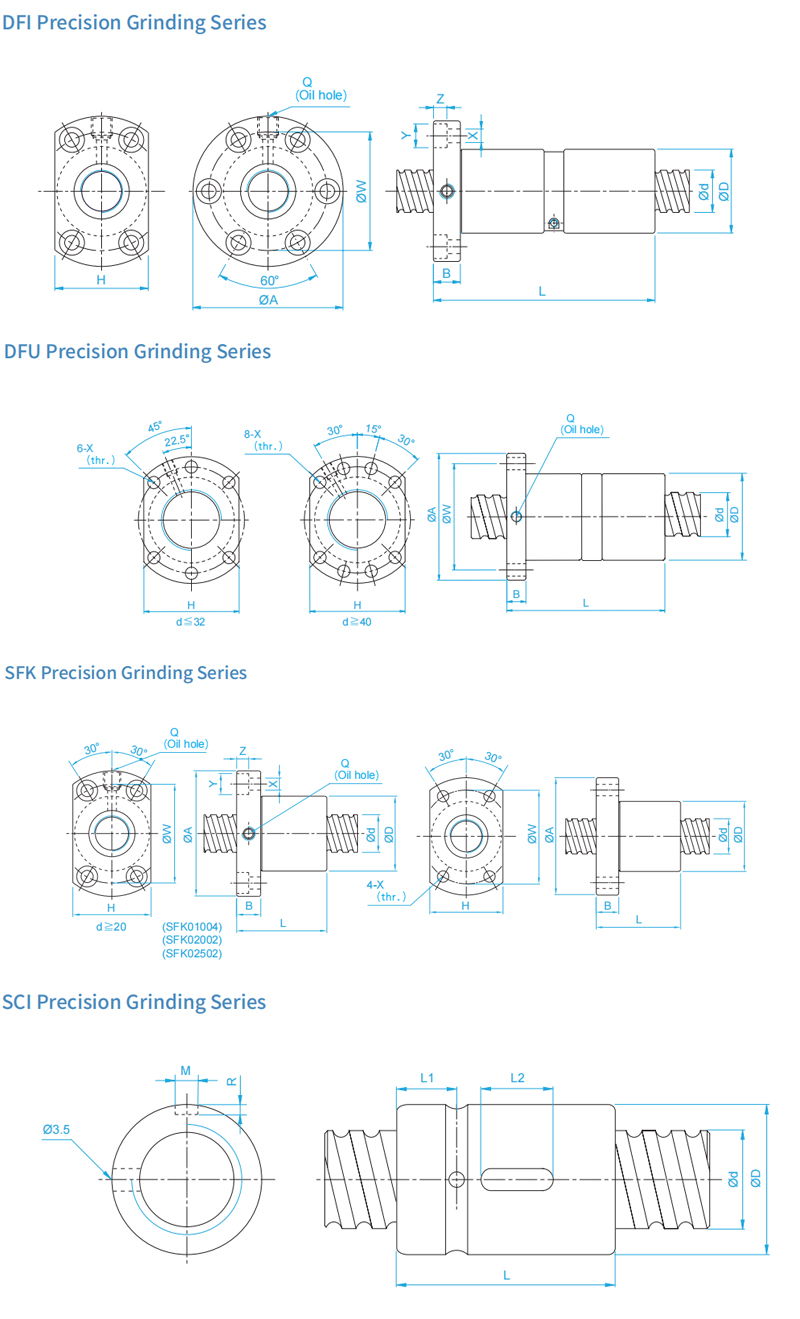

Double-Nut Ball Screw with High Precision

Ball screws are widely used in machinery, especially along the feed axes of CNC machine tools. The ball screw has the characteristics of high precision, high rigidity, micro-feed and high-speed feed. However, the clearance between the balls and rollers can cause errors in the ball screw. To solve this problem, a double nut ball screw was developed. The preloading methods of the double nut ball screw mainly include positioning preloading and constant pressure preloading. Currently, the most common application of detent preload is to add a rigid washer between two nuts to create an axial relative offset between them, thereby creating an axial thrust. Different thicknesses of shims can be used to control the preload. The constant pressure preload is mainly due to the axial elastic tension generated by the spring installed between the two nuts. This is the axial preload of the ball screw, approximately constant. The positioning preload method was used in this study.

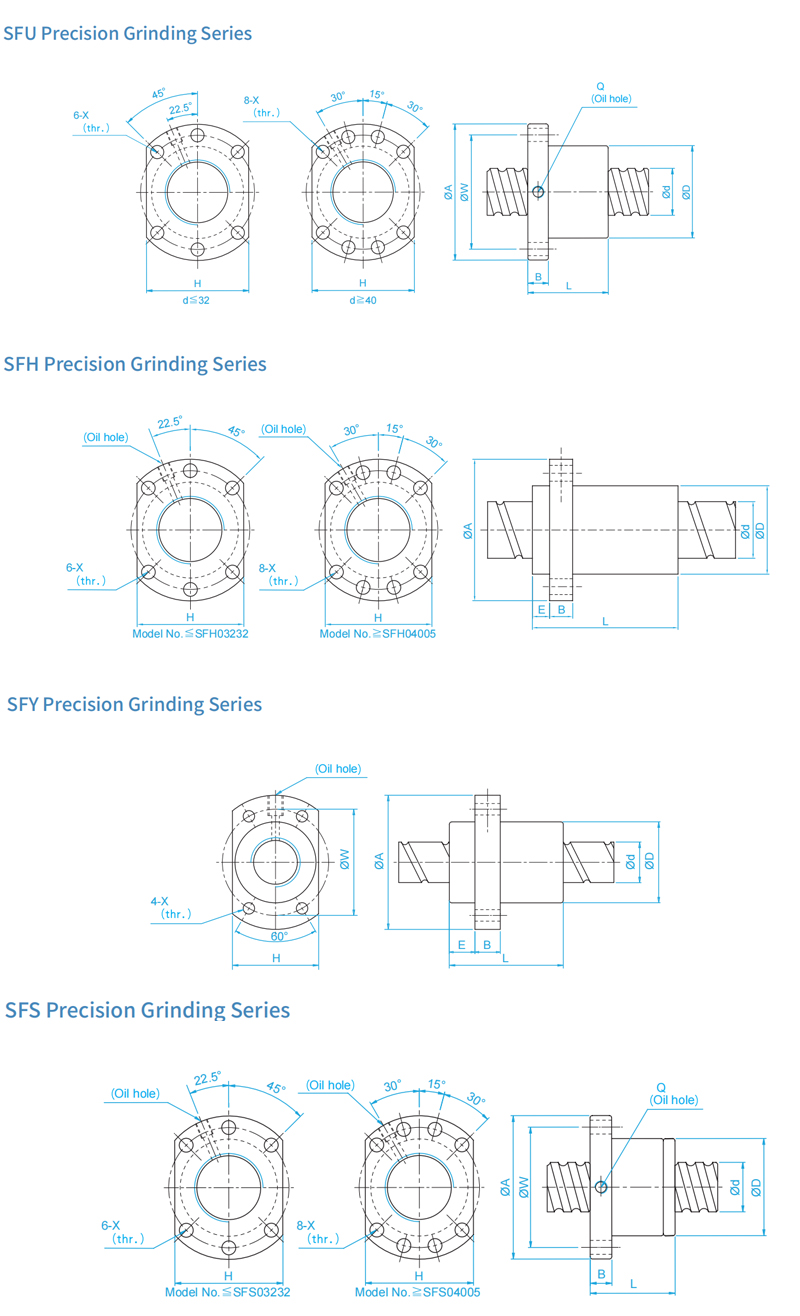

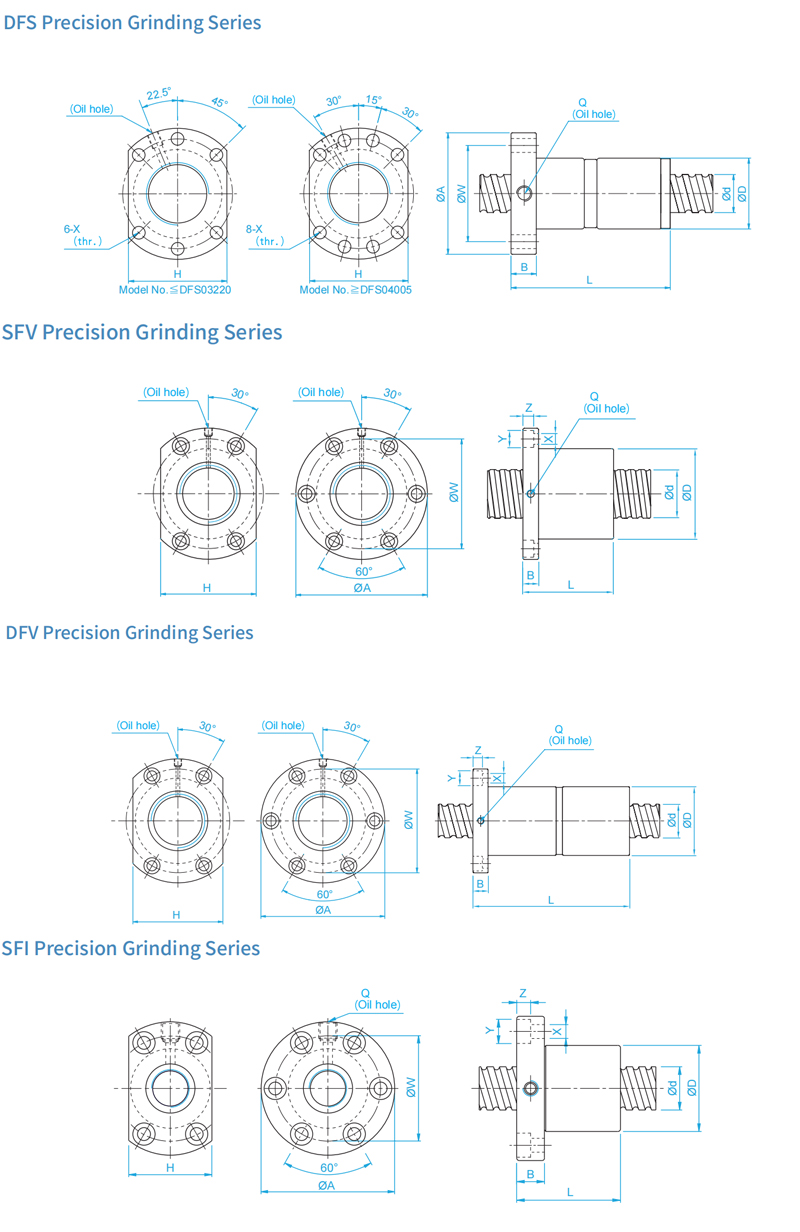

Product model selection

Note: Other sizes,and nut shapes are available upon request !

Related Keywords