0.9 degree nema17 hybrid stepper motor

-

$20.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- ShangHai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShangHai |

17HA Series

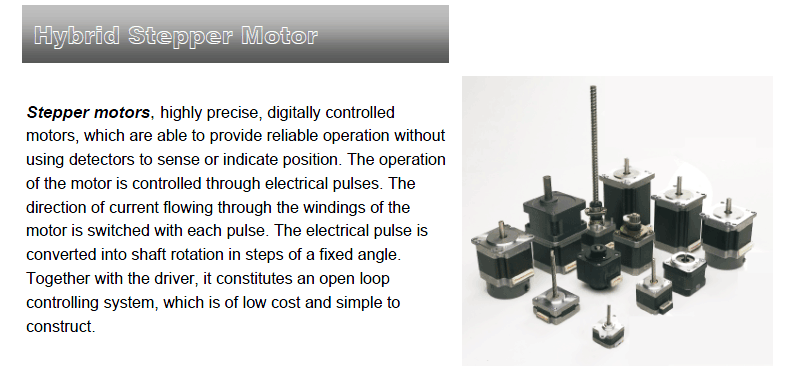

The stepping motor is limited by its own manufacturing process. For example, the step angle is determined by the number of rotor teeth and the number of operating beats, but the number of rotor teeth and the number of operating beats are limited. Therefore, the step angle of a stepping motor is generally large and Fixed, low stepping resolution, lack of flexibility, vibration at low frequency, higher noise than other micromotors, making physical devices easy to fatigue or damage. These shortcomings make the stepper motor can only be used in some low-demand occasions. For the high-demand occasions, closed-loop control can only be adopted, which increases the complexity of the system. These shortcomings severely limit the stepper motor as an excellent open-loop Effective use of control components. Subdivision drive technology effectively overcomes these shortcomings to a certain extent.

Positional error: ±5%;

Working Temperature: -10℃-+40℃;

Temperature rise: 85K;

Insulation resistance: 100Mohm min 500V DC;

Insulation class: B.

Characteristics

Precise Position Control

The specified number of pulses determines the output degree(s) generated.

Linear Speed Selection

The running speed is linearly variable and determined by the frequency of the pulses.

Forward & Reverse, Pause and Holding Function

The forward & reverse rotation is controlled by the polarity. There is still holding torque even while the motor rotor is being locked. There is still current flowing through the motor winding, but no pulse signal creating rotation from the outside controller.

Low Speed Feature

Low frequency pulses being input, a stepper motor can operate at very low rotating speeds. This can be done

without a speed reduction gearbox and thereby save power and maintain precision.

Long Life

The brushless design provides stepper motors with a very long life. In fact, the stepper motor life is determined

by the life of the bearings. Stepper motors are widely being used in many types of digitally controlled motion

control applications, such as printers, intelligent (performance) stage lighting, office, bank and industrial equipment, medical, packaging, textile, aerospace, robotics and automotive

Our product series

1.STEPPER MOTOR

2.BALL SCREW:

SFU SERIES,SFE SERIES,M-ISNF SERIES,M-ISNA SERIES,M-CSNF SERIES BALL SCREW

3. LEAD SCREW

4. AKD SUPPORT UNIT

5. LINEAR GUIDEWAY

6.COUPLING

Why choose us ?

1. Screwtech designs, manufactures, supplies a complete selection of inch and metric linear mechanical parts and systems to the Linear Motion and Power Transmission Industries.

We accept customised products upon request!

2. Our products include:

1)Miniature Ball Screw with diameter from 4mm-16mm, lead from 1mm to 10mm.

2)Stainless Steel or 1045 Steel Lead Screw with POM or Brass Nut, diameter from 3.5mm to 80mm

3)Stainless Steel Ball Screw, Lead Screw

4)AKD Support Unit of Ball Screw, Lead Screw

5)Linear Guideways

6)Stepper Motor

7)Flexible and Rigid coupling

We believe we’ll be the right supplier for all the linear machinery that you need.Hope could have the honor to cooperate with youJ!

Package and delivery

We have DHL, FEDEX VIP account,so the shipping freight will be much cheaper after discount.

The marked price in the website is not the authentic transaction value. Because the category of screw’s products belongs to customized products, the actual price should be given corresponding discount by products’ specifications and order qty.

Related Keywords