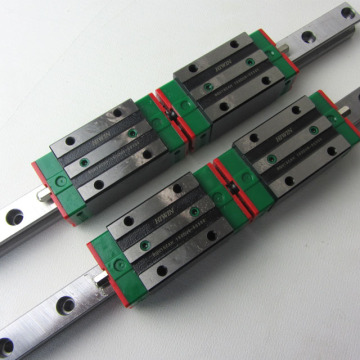

LGC type Linear guideway

The function of linear guide motion is to support and guide the moving parts to make reciprocating linear motion in a given direction. Depending on the nature of friction, linear motion guides can be divided into sliding friction guides, rolling friction guides, elastic friction guides, fluid friction guides and other types. Linear bearings are mainly used in automated machinery, such as machine tools imported from Germany, bending machines, laser welding machines, etc. Of course, linear bearings and linear shafts are matched. Linear guides are mainly used in mechanical structures that require relatively high precision. There is no intermediate medium between the moving and fixed components of the linear guide, but rolling steel balls.

Key Features

1.Built-in long life lubrication

2.High positional accuracy

3.High speed motion is possible with a low driving force

4.Equal loading capacity in all directions

5.Easy installation

6.Inter change ability

Specification

The new RG series from Hiwin features a roller as the rolling element instead of steel balls. The roller series offers super high rigidity and very high load capacities. The RG series is designed with a 45-degree angle of contact. Elastic deformation of the linear contact surface, during load, is greatly reduced thereby offering greater rigidity and higher load capacities in all 4 load directions.The RG series linear guideway offers high performance for high-precision manufacturing and achieving longer service life.

Rolling circulation system: Block , Rail , End cap , Circulation path, rollers

Lubrication system: Grease nipple and piping joint

Dust protection system: End seal, Bottom seal, Cap, Double seals and scraper

Advantages

(1) Optimal design

fEM analysis was performed to determine the optimal structure of the block and the rail. The unique design of the circulation path allows the RG series linear guideway to offer smoother linear motion.

(2) Super high rigidity

The RG series is a type of linear guideway that uses rollers as the rolling elements. Rollers have a greater contact area than balls so that the roller guideway features higher load capacity and greater rigidity.

(3) Super high load capacity

With the four rows of rollers arranged at a contact angle of 45-degrees, the RG series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. The RG series has a higher load capacity in a smaller size than conventional, ball-type linear guideways.

(4) Operating life increased

Compare with the ball element, the contact pressure of rolling element is distributed on the line region. Therefore, stress concentration was reduced siginificantly and the RG series offers longer running life. The nominal life of RG series can be calculated by using Eq.

Application

Automation Device

Transportation equipment

CNC machining centers

Heavy duty cutting machines

CNC grinding machines

Injection molding machines

Electric Discharge Machines

Plano millers

Devices requiring high rigidity and high load capacity

Types

(1) Block types

HIWIN offers two types of guide blocks, flange and square type. Because of the low assembly height and large mounting surface, the flange type is excellent for heavy moment load applications.

(2) Rail types

In addition to the standard top mounting type, HIWIN also offers the bottom mounting type of rails.

Standard and Maximum Lengths of Rail

HIWIN offers a number of standard rail lengths. standard rail lengths feature end mounting hole placements set to predetermined values (E). for non-standard rail lengths, be sure to specify the E-value to be no greater than 1/2 the pitch (p) dimension. An E-value greater than this will result in unstable rail ends.

Related Products

1.STEPPER MOTOR

2.BALL SCREW:

SFU SERIES,SFE SERIES,M-ISNF SERIES,M-ISNA SERIES,M-CSNF SERIES BALL SCREW

3. LEAD SCREW

4. AKD SUPPORT UNIT

5. LINEAR GUIDEWAY

6.COUPLING

Why choose us ?

1. Screwtech designs, manufactures, supplies a complete selection of inch and metric linear mechanical parts and systems to the Linear Motion and Power Transmission Industries.

2 Professional manufacturer

We have the professional production team, high precision production equipments ,focused on precision transmission parts for more than 10years and have our own brand name WKT .

3 Quality control

1).We have QC department to control quality for each step.

2).We also have Automatic product equipments(German Chiron FZ15W ,DMG MORI MAX3000 Machining Centers ) which can cantrol the precision itself

3).ISO9001:2008

4 Competitive Price

Screw Technology is a manufactory which can export directly to customer, so there is no intermediary cost involved.

5 Quickly Delivery

We are big manufacturer ,have large amount of stock, we can delivery customer's order just-in-time for small order, 7-15 days for big order.

6 Best After-Sale Service

Screw Technology supply the after-sale service and technical assistance as per customer's requirement and needs. Customers are always given quick support.