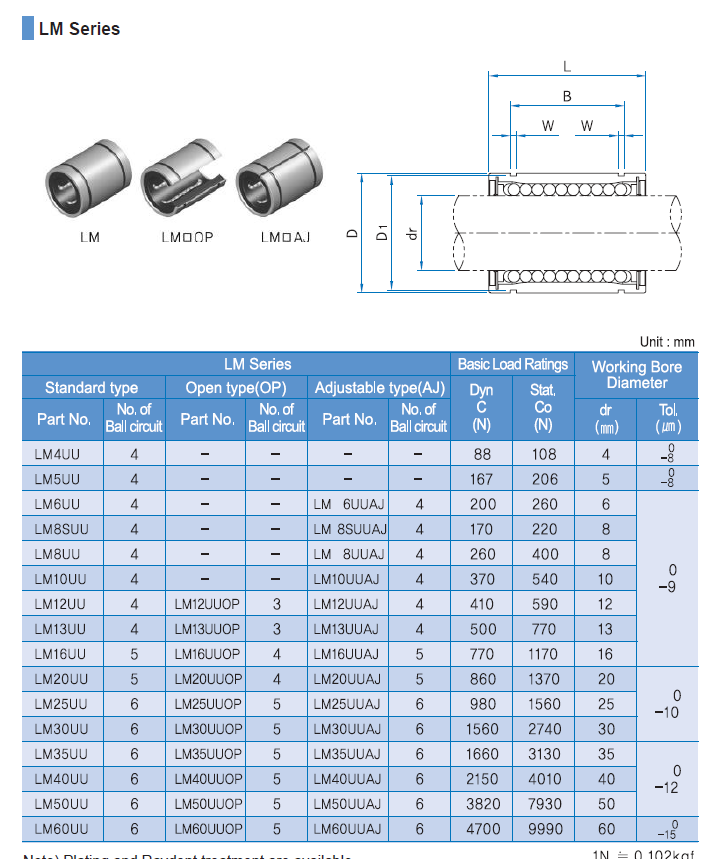

High precision LM series linear ball bushing

-

$90.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,Express Delivery,CFR,CIF,DAF,DES,EXW,FAS,FCA,CPT,DEQ,CIP,DDP,DDU |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Motorized linear slides such as machine slides, CNCmachin, XY tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. XY Tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis.

Closed loop servo control

Closed-loop servo control, control accuracy up to 0.01mm; precise control of thrust, adding pressure sensor, control accuracy up to 1%; it is easy to connect with PLC and other control systems to achieve high-precision motion control. Low noise, energy saving, clean, high rigidity, impact resistance, long life, simple operation and maintenance. The electric cylinder can be trouble-free in harsh environments, and the protection level can reach IP66. Long-term work, and achieve high-intensity, high-speed, high-precision positioning, smooth movement, low noise. So it can be widely used in paper industry, chemical industry, automobile industry, electronics industry, machinery automation industry, welding industry, etc.

Low cost maintenance

The electric cylinder only needs regular grease injection and lubrication when working in a complex environment, and there are no wearing parts that need maintenance and replacement, which will reduce a lot of after-sales service costs compared with hydraulic systems and pneumatic systems.

The best substitute for hydraulic cylinders and cylinders: Electric cylinders can completely replace hydraulic cylinders and cylinders, and achieve the advantages of a more environmentally friendly, more energy-saving, and cleaner environment. It is easy to connect with PLC and other control systems to achieve high-precision motion control.

Configuration flexibility

Can provide a very flexible installation configuration, a full range of installation components: install front flange, rear flange, side flange, rear hinge, trunnion installation, guide module, etc.; it can be installed in line with the servo motor or in parallel; Add various accessories: limit switch, planetary reducer, pre-tightening nut, etc.; drive can choose AC brake motor, DC motor, stepper motor, servo motor.

Related Keywords