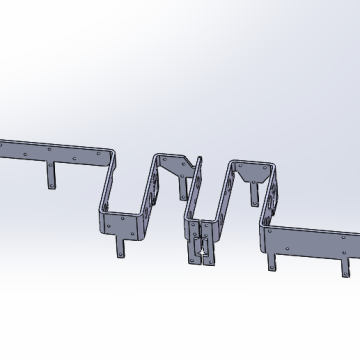

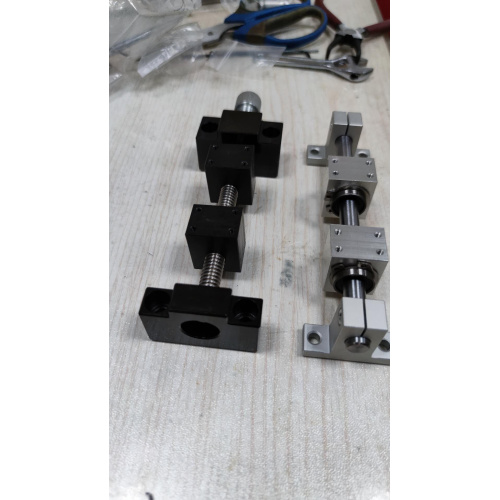

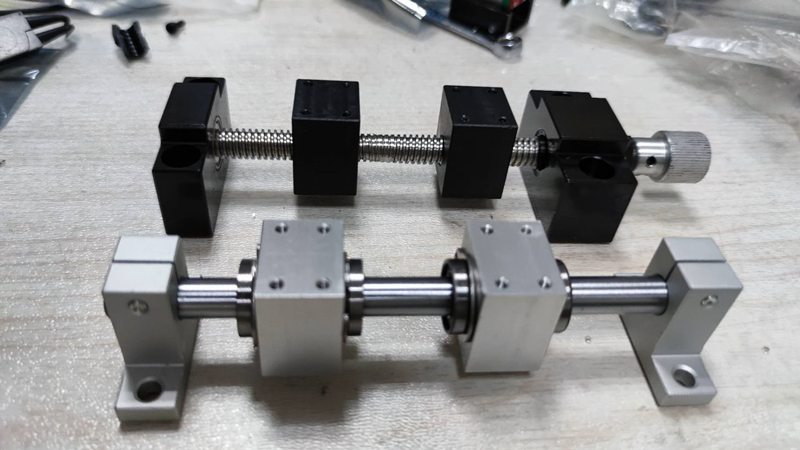

Custom design Sharpener Clamping Device

-

$190.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,Express Delivery,CFR,CIF,EXW,FAS,FCA |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

Module development process:

Linear modules were first developed and used in Germany. The market is positioned in photovoltaic equipment, loading and unloading robots, cutting equipment, gluing equipment, placement equipment, etc. This type of robot can bring comfort to the equipment in this industry: the unique body has the characteristics of fast moving speed, high repeat positioning accuracy, light weight, small equipment space and long service life. The application range of linear modules has been extended to all parts of the world. In our country, the operation speed is relatively fast. In recent years, the development of linear modules has been even faster, especially in Shenzhen, where many things have been done, and the quality is very good, and it has been highly favored by equipment manufacturers.

Due to the development of linear modules, it has been widely used in various devices. It has made an indispensable contribution to the development of my country's equipment manufacturing industry, reduced dependence on imported complete sets of equipment, and provided more opportunities for engineers interested in equipment research, development and manufacturing. Linear modules are currently widely used in measurement, laser welding, laser cutting, gluing machines, spraying machines, punching machines, dispensers, small CNC machine tools, engraving and milling machines, plotters, and cutting machines. Places such as transfer machines, sorters, applicable testing and education machines.

Currently widely used linear modules can be divided into two types: timing belt type and ball screw type.

The main components of the synchronous belt linear module are: belts, linear guides, aluminum alloy profiles, couplings, motors, photoelectric switches, etc.

The ball screw type linear module is mainly composed of: ball screw, linear guide, aluminum alloy profile, ball screw support seat, coupling, motor, photoelectric switch, etc.

What types of linear modules are available:

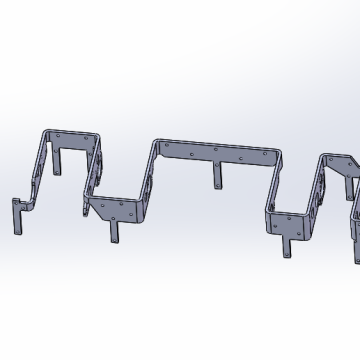

Synchronous belt type:

The working principle of the synchronous belt type is: the belt is installed on the drive shaft on both sides of the linear module and used as the power input shaft, and the slider is used to increase the equipment work piece and it is fixed on the belt. When inputting, the slider is moved by the driving belt.

Generally, the timing belt module is specially designed, and the elasticity of the belt movement can be controlled on one side, which is convenient for equipment debugging during the production process.

Synchronous belt linear module can choose to increase the rigid guide rail according to different load requirements to improve the rigidity of the module. Slide modules of different specifications have different upper load limits.

The accuracy of the synchronous belt linear module depends on the quality of the belt and the processing process. At the same time, controlling the power input will also affect its accuracy.

Screw type:

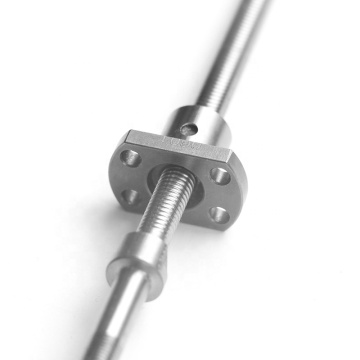

1. The ball screw is an ideal product to convert rotary motion into linear motion or linear motion into rotary motion. The ball screw is composed of screws, nuts and balls. Its function is to convert rotary motion into linear motion, which is an extension and further development of the ball screw. The important significance of this development is to change the bearing from rolling motion to sliding motion. Ball screws are widely used in various industrial equipment and precision instruments due to their low frictional resistance. High-precision linear motion can be achieved under high load conditions.

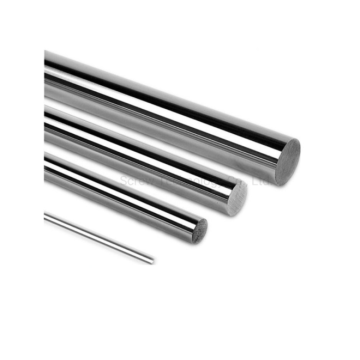

2. Linear guide rails, also known as slide rails, linear guide rails, linear slide rails, used for linear reciprocating motion applications. Compared with linear bearings, they have a higher rated load and can bear a certain torque at the same time to achieve high accuracy under high loads. Straight line movement. High structural precision; precision guide rail board.

3. The aluminum profile sliding table has beautiful appearance, reasonable design, good rigidity and reliable performance. It is an ideal basic power component for modular machine tools and automatic production lines. It has good dynamic performance. The sliding table has high rigidity, small thermal deformation and high feed stability to ensure the true accuracy under the processing state (under load).

There are mainly two common linear modules, one is ball screw drive, the other is synchronous belt drive, the two transmission methods have their own advantages and disadvantages in terms of performance, please see the analysis of Sidouqiu:

The main advantage of the ball screw drive method is high precision. It can achieve a repeatable positioning accuracy of 0.006mm. The horizontal load capacity of the screw rod is similar to the horizontal load capacity of the belt module. However, it is generally not recommended to use a vertical load for the timing belt. The running speed of the screw slide table will be slower than that of the timing belt, but it is also related to the selected screw pitch, motor and module type. Pay attention to the maintenance of the screws during the use of the linear module of the ball screw. Usually, after moving a certain distance, it is necessary to clean the dirt and replace the grease in time.

The characteristic of the synchronous belt drive mode is that the running speed is relatively fast, the general speed can reach 1m-2m/s, and the stroke can reach 3 meters. The disadvantage of the synchronous belt module is that the ordinary belt requires a higher maintenance frequency, and the accuracy of repeated positioning is usually 0.1mm lower than that of the lead screw drive. Therefore, these two transmission methods can be selected according to equipment requirements.

Use:

Rotate the knob, the lead screw drives the nut to slide in the middle, and then drive the mounting seat on the screw to slide in the middle through the connecting piece, and then tighten the ice skates on the skates to sharpen the knife

Application:

Clamping, grinding, rotation device

Related Keywords