Tr16x4 lead screws with POM nut

-

$35.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- ShangHai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | EXW,CIF,CFR,FOB,FAS,FCA,CPT,Express Delivery |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShangHai |

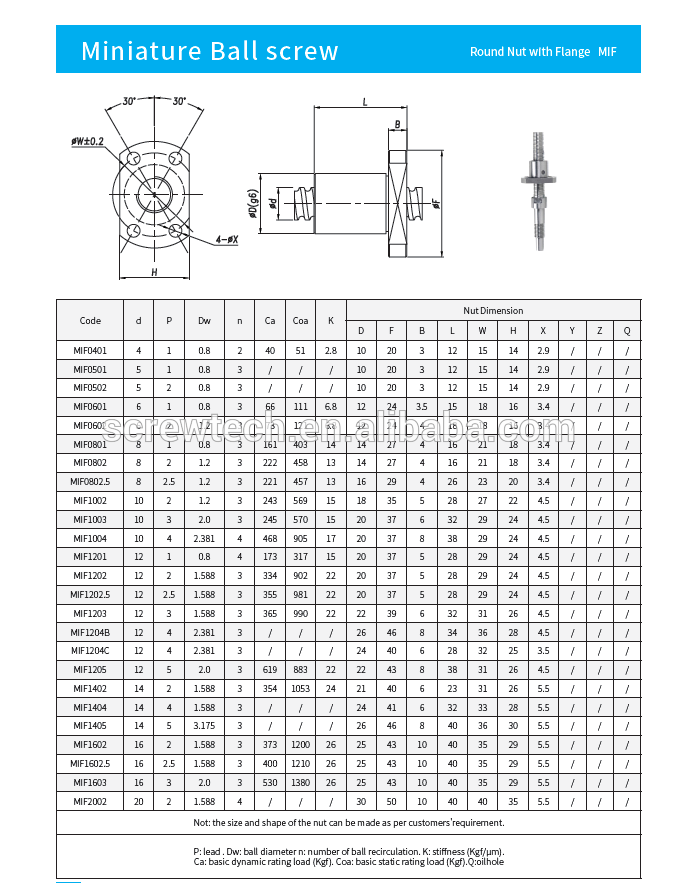

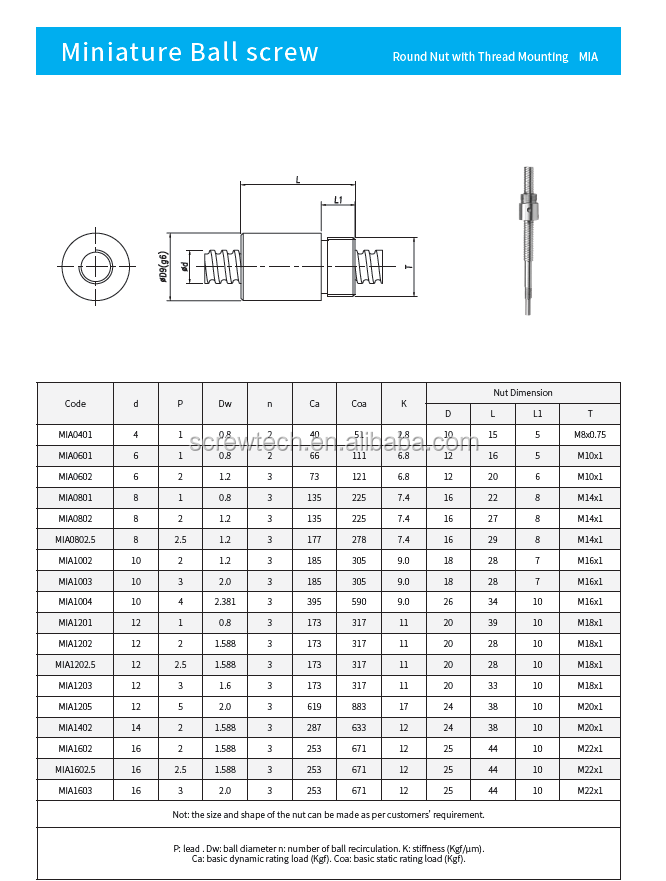

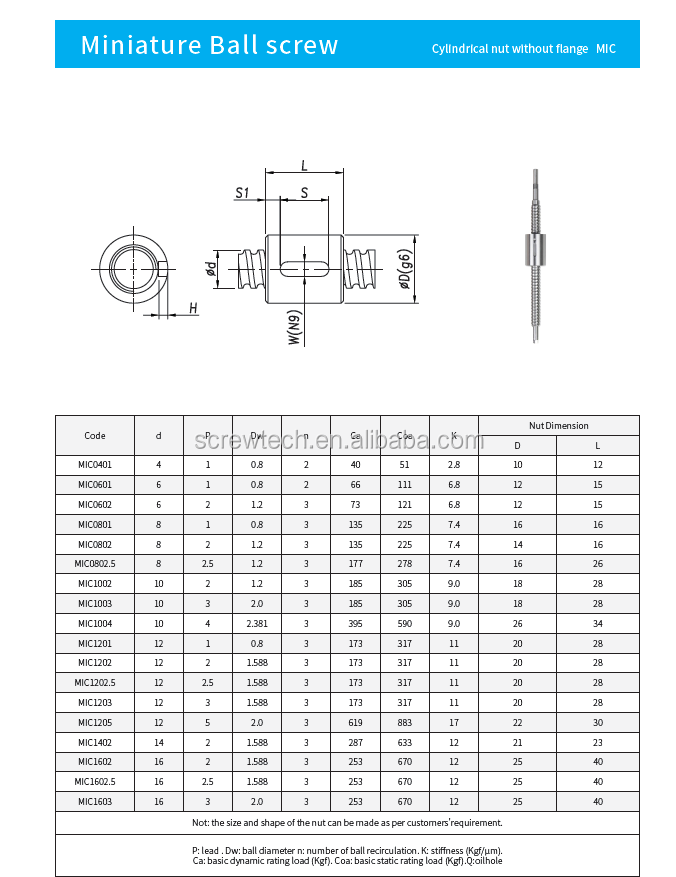

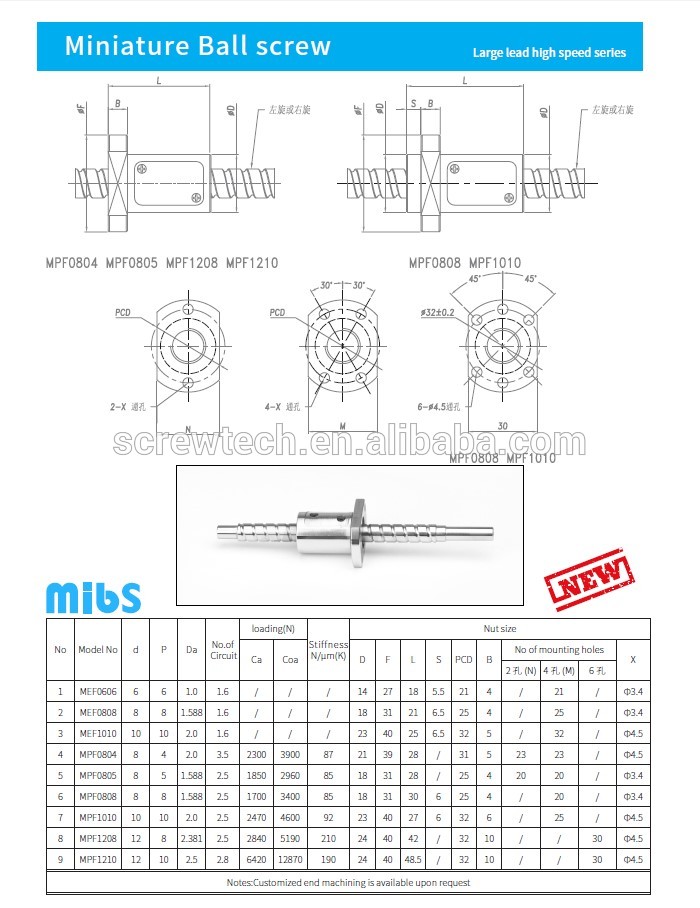

6mm Diameter Miniature Ball Screw with factory price for CNC machine

The equipment is refitted by a lathe, the workpiece is rotated, and the cutter head and knurled tool holder are moved. Remove the lathe tool holder part, install the milling head and self-made tool holder on the slide plate, install the knurling tool on the tool holder, and place the tool holder in front of the milling cutter head. The left end of the workpiece is clamped with a chuck, the tailstock is removed at the right end, and a bracket with a longer hollow tube is installed, so that a longer material can be clamped at a time (equivalent to more than twice the length of a milling), and the milling part can be cut and processed. Reduce end material waste.

When specially designed, the polished rod drives the lead screw to rotate in the nut, the left end of the lead screw is equipped with a spring chuck, and the workpiece rotates to the left to feed. Both the polished rod and the lead screw are processed by hollow tubes (to reduce end material waste). Because the middle is suspended for a long time, you can consider supporting it with an auxiliary bracket.

The clamping device of the knurling knife. The knurling tool device of the two designs is the same, but the connection part between the support frame and the machine tool is different. Machining a hole on the support frame, milling grooves and through-holes on the opposite side of the processed part through the center line of the hole: the width of the groove is the same as the knurled tool holder, the depth is the same as the height of the tool holder, and the bottom of the groove near the slot connection hole is perpendicular to the root of the bottom groove A narrow slot is milled to facilitate the outflow of fine iron filings extruded by the knurling, and prevent the knurling wheel from stagnating and jamming. The knurled knife is pressed by a quick-change cover, and the knurled knife handle is tightened by a screw rod with a plum blossom handle. The round steel is knurled after passing through the guide sleeve, and then is milled at a high speed to complete the two processes at one time. The guide sleeve is made of quenched and tempered tool steel, and an opening is milled on it, and the length is flat with the end surface of the bracket. The guide sleeve positioning pin hole, the assembly screw and the bracket are matched, and the opening must be directly aligned with the center line of the groove.

|

Material

|

GCR15 or Stainless Steel, others available upon request

|

|

Dimension

|

Diameter : 6mm, Lead : 2mm

|

|

Thread Direction

|

Right hand ( Left hand and bi-directional all available)

|

|

Accuracy Grade

|

C3 C5 C7

|

|

Application

|

Automatic controlling machines, semi-conductor industry, general industrial machinery, machine tools, medical equipment, parking systems, measuring instrument, Automatic computer strip machine, Gantry cranes, Gantry robot, 3D engraving machine etc.

|

|

Remark

|

Various ballnuts are available upon drawing

|

1. We Screwtech is a professional manufacturer of Ball Screws, Lead Screws. Meanwhile, Distributing Stepper Motor, Linear Guideway, AKD-Support for ball screw, Coupling, Linear Module for more than 10 years.

2. As the unique and professional original factory, we can offer you products of high quality with competitive price and fast delivery.

3. Customized service: Various models are available upon request.

4.We can produce the same size as that from HIWIN, TBI, PMI, and THK.

Features of our mini ball screw

※ High mechanical efficiency

※ Zero Axial play

※ Accuracy grade of C3, C5, C7

※ Long service life

※ Smooth running

In cartons or Wooden cases upon your requirement

For samples:

we have DHL, FEDEX VIP account, so the shipping freight will be much cheaper after discount.

For bulk order:

we have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

Port:

Shanghai

Lead Time:

10~30 days

Related Keywords