ACME 11/16-5 lead screw with square nut

-

$17.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- ShangHai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SuZhou |

|---|---|

| Productivity: | 2000pcs/month |

| Supply Ability: | 2000pcs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | Express Delivery,FOB,CFR,CIF,DAF,EXW,DES,FAS,FCA |

| Certificate: | IATF16949 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | ShangHai |

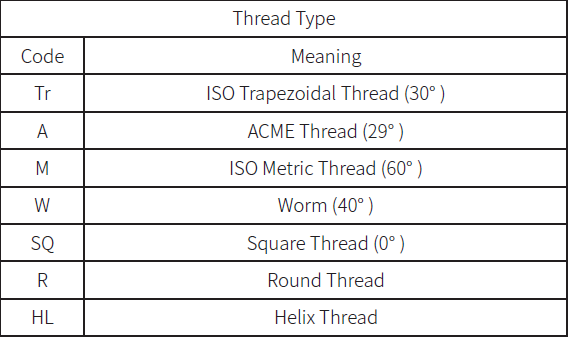

A lead screw is a difficult-to-machine sliding feed screw with a 45° lead angle. Its large lead angle is best suited for fast reciprocating feed at low speeds.

Can easily convert linear motion to rotary motion and rotary motion to linear motion with 70% efficiency. Because of the large lead, it is most suitable for the manufacture of fast-forward mechanisms that rotate at low speeds

Turning was used for lead screw processing. The process route is: cold drawing→knurling→threading→correction→drilling→cutting→chamfering. It is easy to be deformed at times, and the small screw wheel cannot be produced. For this reason, we have designed a whirlwind milling screw equipment, which not only increases the speed from the experience-recognized 1000r/min to more than 2000r/min, but also completes the milling and knurling at one time. The process route becomes: cold drawing→knurling, wire milling→correction→drilling, cutting→chamfering. Although whirling milling causes large deformation of small-diameter workpieces (smaller deformation of large-diameter workpieces), correction is also easy. The improved process has the following characteristics:

The surface roughness value decreases;

Vibration caused by cutting forces is reduced;

The cumulative error of the pitch of the small-diameter workpiece increases to a certain extent.

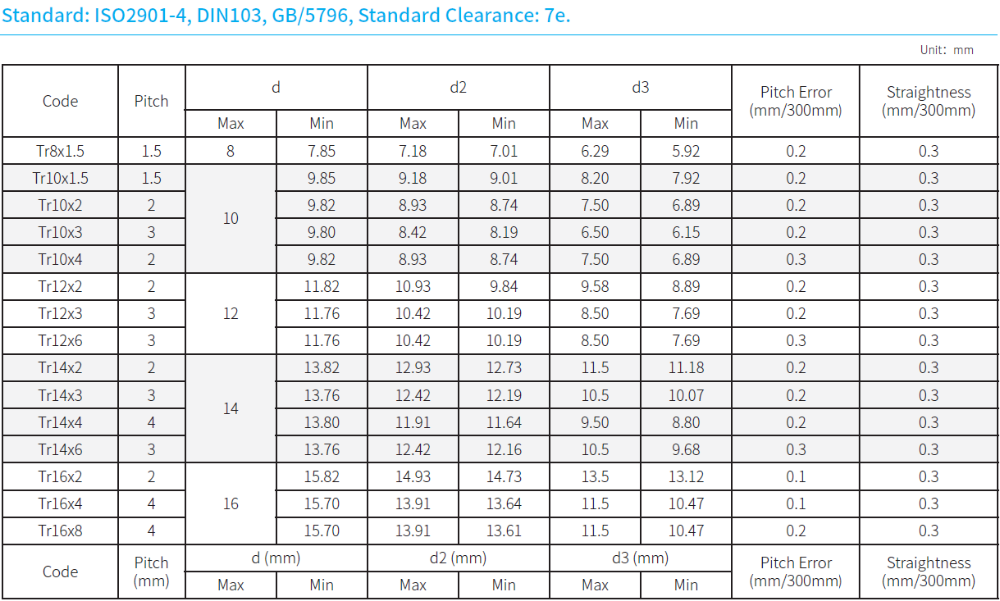

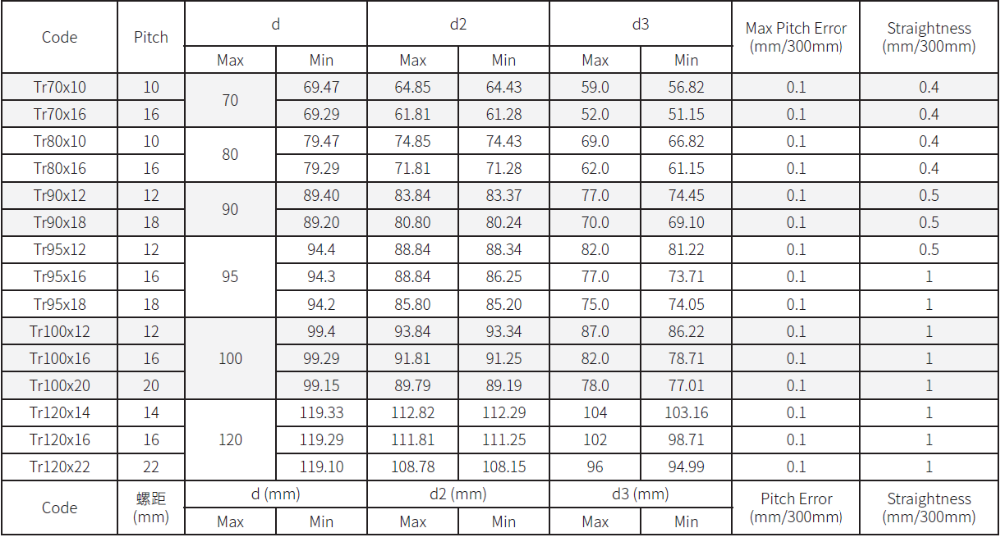

Good quality Trapezoidal Lead Screw Tr10x2

|

Material

|

Stainless Steel,1405 carbon steel,SUS303,SUS304,Ductile cast iron ,others available upon request

|

|

Dimension

|

Diameter : 10mm, Lead : 2mm

|

|

Thread Direction

|

Right hand ( Left hand and bi-directional all available)

|

|

Accuracy Grade

|

7e

|

|

Application

|

Automatic controlling machines, semi-conductor industry, general industrial machinery, machine tools, medical equipment, parking systems, measuring instrument, Automatic computer strip machine, Gantry cranes, Gantry robot, 3D engraving machine etc.

|

|

Remark

|

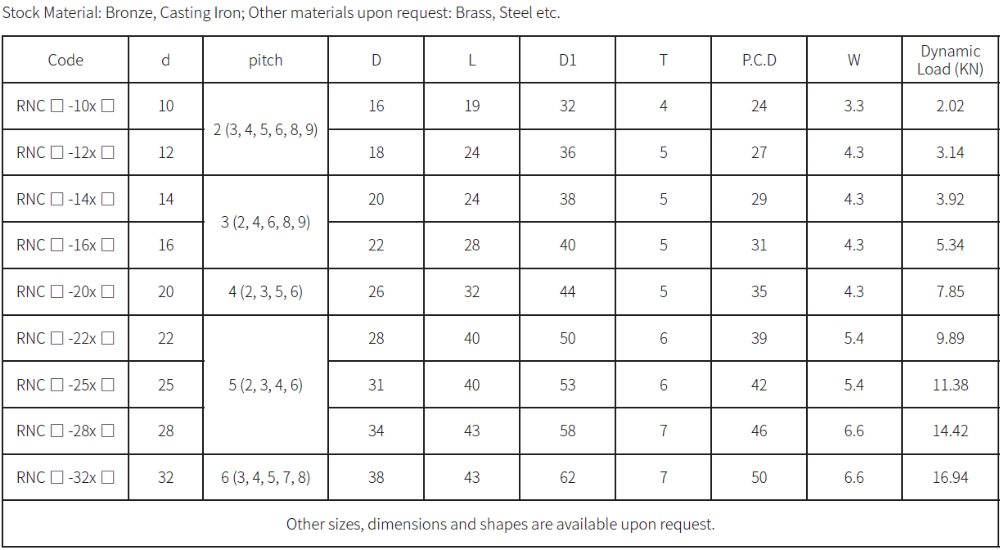

A broad range of lead nuts are available including anti-backlash nuts.

Available material:POM, Brass, Bronze and so on.. |

SCREWTECH'S lead screw series:

6.Right-hand and left-hand thread lead screw type specimen book.

SCREWTECH'S lead screw features:

1.Fast delivery from 5 days to 20 days at most

2.High quality

3.Good surface smoothness

4.Low friction

5.Good straightness

6.We are factory directly supply

In cartons or Wooden cases upon your requirement

For samples:

we have DHL, FEDEX VIP account, so the shipping freight will be much cheaper after discount.

For bulk order:

we have freight forwarder to ship by air,by train or by sea.You can also arrange shipping through your own agent.

Port:

Shanghai

Lead Time:

10~30 days

Related Keywords