Stator Coil Insulation Systems for EV Motor

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou,China |

|---|---|

| Productivity: | 20000-30000pcs per year |

| Supply Ability: | 10 Sets per year |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW,DDP |

| Certificate: | ISO 9001; CE certificate |

| HS Code: | 8419899090 |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI |

Product Introduction

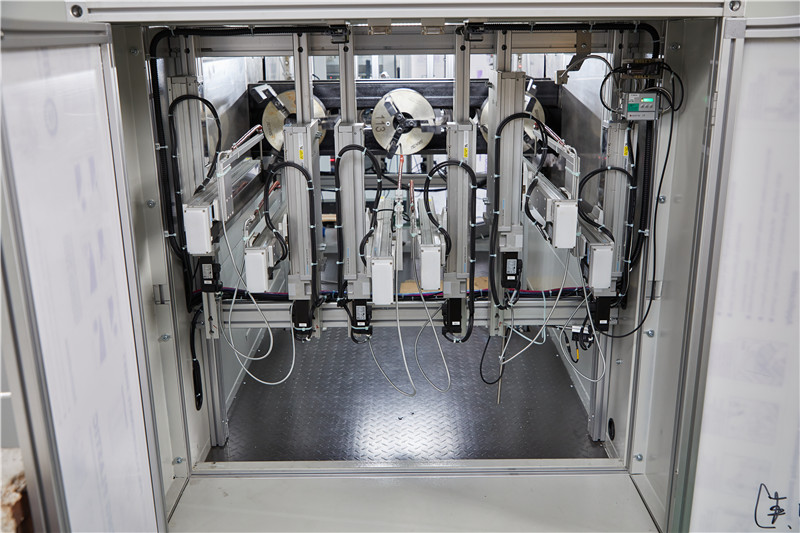

Trickle impregnation of armature stators can be accomplished on the Ev Drive Motor Stator Varnishing Machine with grippers and tooling of variable designs,to properly hold the parts. Possible for Stator Insulating Line Loading System to position the trickle applicators well, depending upon the size and configuration of the range of stators. JINLAN can also provide customized Stator Resin Dispensing Solution to accommodate larger stators. The Stator Insulating Line Servo Pumps offer quantitative resin control to meet special production needs. Various levels of automation available for Electrical Motor Stator Impregnation process,such as robot load and unload, programmed positioning of trickle applicators.

Product Features

flexible model changeover, temperature zone control, data traceability, and varnish quantitative control

Process Parameters

Applicable product model

Flat copper wire/round copper wire

/

load/unload system

manual/robot

Can be connected with the production lines both in front and at the back

Product clamping

Inner supporting/external clamping

To be designed according to the product model

Output accuracy

1%-10%

Multiple configurations, to be designed based on customer specification

Single machine cycle time

≥45s

Depending on product model

Varnish type

Single component/two- component

Varnish temp control

10-50℃

Varnish temp will be protected in heating and cooling working system

Flow rate monitor

pressure/flow rate monitor

Anti-clogging/fail-safe monitor

Related Keywords