EV Drive Motor Stator Impregnation Line

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- SHANGHAI

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | SUZHOU,CHINA |

|---|---|

| Productivity: | 20 SETS PER YEAR |

| Supply Ability: | 20 SETS PER YEAR |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Certificate: | ISO quality system certificate;CE certificate |

| HS Code: | 8419899090 |

| Transportation: | Ocean,Land,Air |

| Port: | SHANGHAI |

Product Introduction

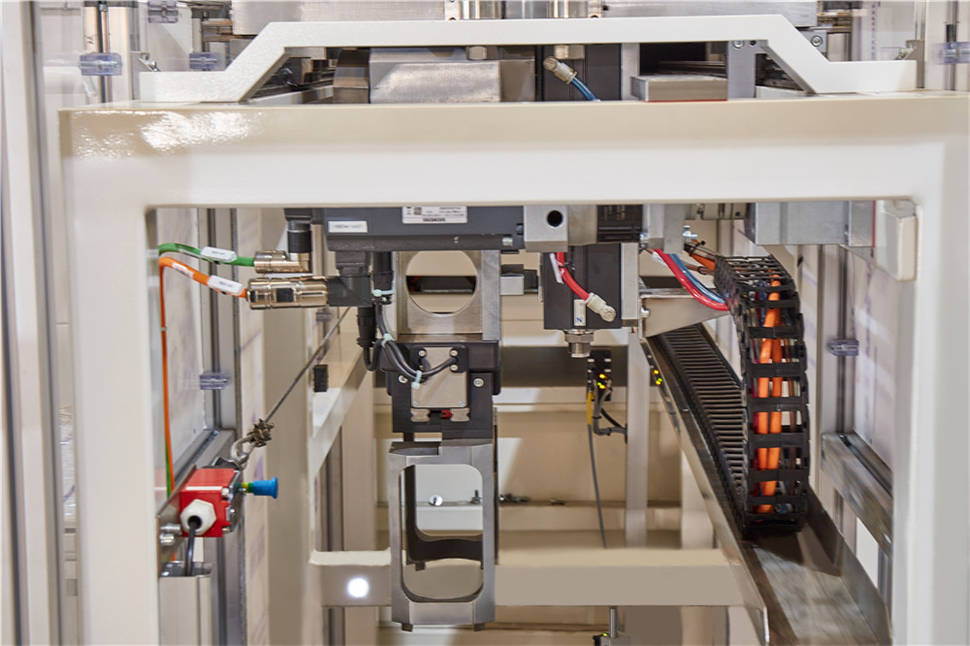

The stator will be varnished on copper coils before solidified, to achieve insulation effect as desired. The servo trickling module, high-accuracy scale and data traceability system help avoid resin stains on the stack. It boasts of being compatible for multiple product models and fast model transfer. You can customize the cycle time according to your request.

Product Pictures

JINLAN serves the industry with three main technologies, automatic assembly, professional test and trickling insulation. The main products we serve includes stator varnishing machine, stator lacing machine,stator leadwire finishing machine,stator test machine;rotor dipping line,rotor assembly line and brushholder assembly line for automotive generator industry; drive shaft assembly line, ORC assembly line,electromagnetic switch assembly line and the general assembly line for starter industry; car seat general assembly line,automatic steel wire cutting machine for automotive seat industry; EPS power head test line for electric power steering system industry; charge cable assembly line, stator impregnation line, stator epoxy coating machine and EV drive motor general assembly line for EV motor industry.

Related Keywords