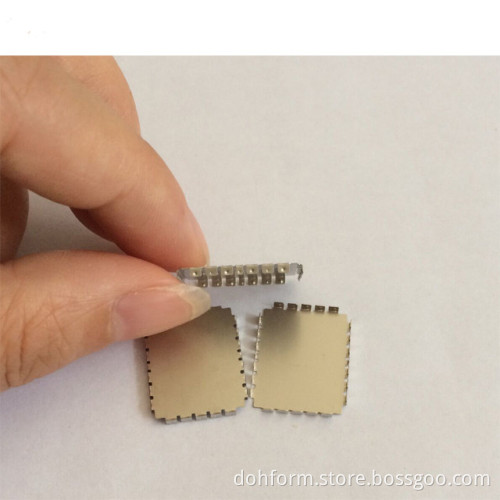

Sheet metal fabrication/mechanical parts/stamping service

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25-30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Kunshan,China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,China |

Sheet metal fabrication/mechanical parts/stamping service

Stamping (also known as pressing) is the processof placing flat sheet metal in either blank or coilform into a stamping press where a tool and diesurface forms the metal into a net shape. Stamping includes a variety of sheet-metalforming manufacturing processes, such aspunching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a singlestage operation where every stroke of the press produces the desiredform on the sheet metal part, or could occur through a series ofstages. The process is usually carried out on sheet metal, but canalso be used on other materials, such as polystyrene. Progressivedies are commonly fed from a coil of steel, coil reel for unwinding ofcoil to a straightener to level the coil and then into a feeder whichadvances the material into the press and die at a predetermined feedlength. Depending on part complexity, the

number of stations in the die can be determined.

| Name | OEM customized precision sheet metal fabrication/mechanical parts/stamping service from China factory |

| Mould material | SKD11/51/61,SKH-9,S136,H13, ASP60, ASP23, S45C, CD650, NAK80,XW-42,2738,8407,718etc. |

| Product material | Steel,copper,brass,bronze,etc.Or as customer's requests. |

| Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,Ultrasonec cleaning machine,injection machine,punching machine,etc. |

|

Detection equipment |

Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc. |

|

Design software |

UG, PROE ,CATIA, SOLIDWORK, CAD,etc. |

|

Mould life |

1-50million shots |

|

Specification |

17 years machining parts processing experience;Precision tolerance less than 0.001mm;Depends on customer’s requirements. |

|

Delivery |

Shipping test sample in 30 days after receive the payment,or according to customer's requests. |

|

Payment terms |

T/T, L/C,D/A,D/P,Paypal, Western Union,etc. |

|

Package |

PE bags add export carton for products,wooden case for mold,or as customer's requirments. |

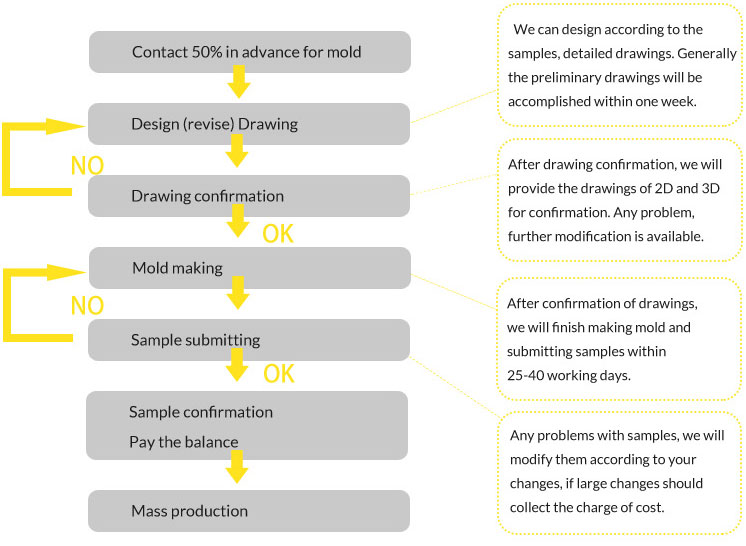

A) Before sales Service

- 24hour online consult

- Sample support

- Detailed technical 2d and 3d drawing design

- Free pick up at hotel/aitport to visit Feiya factory

- Qick and profession response on quotation and technial

B) Production period service

- Technical 2d and 3d drawing submit to double check details and discussion

- Quality inspection report submit,guarantee the accuracy

- Installation solution and maintenance instruction

C) After sales service

- Provide the usage advice and Guide, remote assistance

- 17 Years quality Guarantee

- Any quality problems replace freely

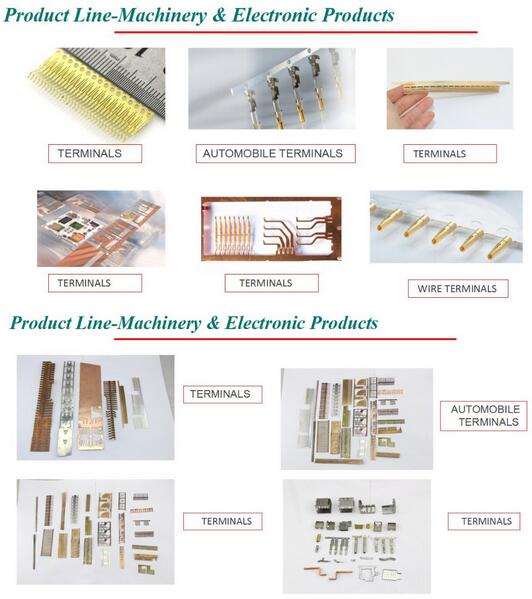

Related Products-Progressive stamping die

Related Keywords