Medical Devices/Medical Precision Tooling/Medical Mold Maker

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25-30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Kunshan,China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,China |

Medical Devices/Medical Precision Tooling/Medical Mold Maker

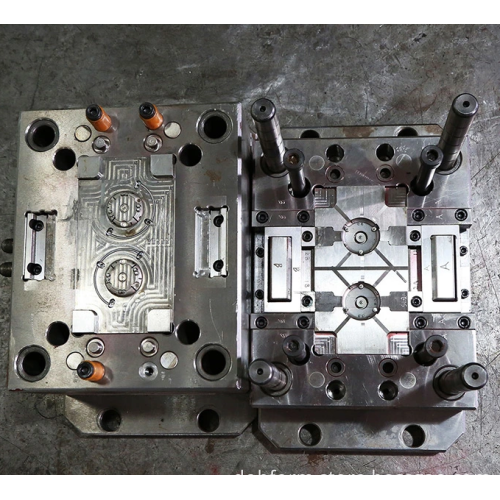

Specifications Plastic injection mold for Medical Precision Tooling,we specializing in precision mold design, manufacturing and high-end plastic injection molding processing. Focusing on precision tooling of Medical Devices moulds, with rich experience in medical products.Products Range:Medical moulds from regular medical disposables to high precise minimally invasive devices, Communication Parts, Household Appliances Parts, Electronics Parts, Cosmetics Parts etc.

Mold 2D + 3D drawing Design:

|

Product name |

Medical Devices/Medical Precision Tooling/Medical Mold Maker |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

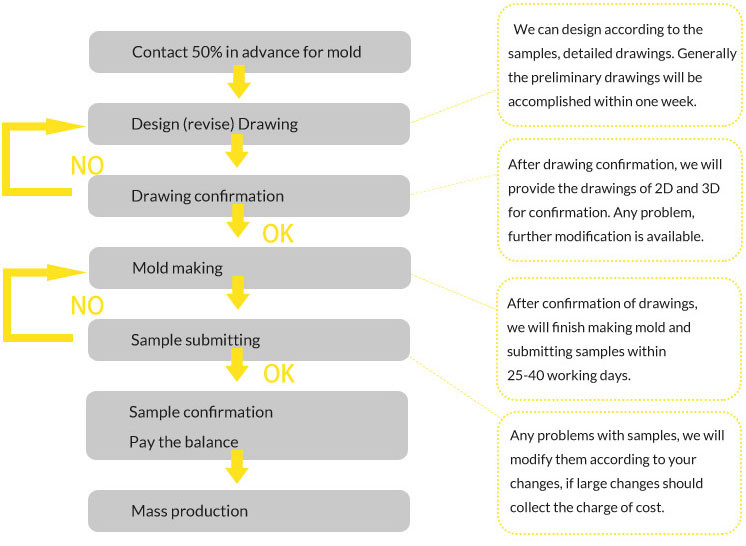

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

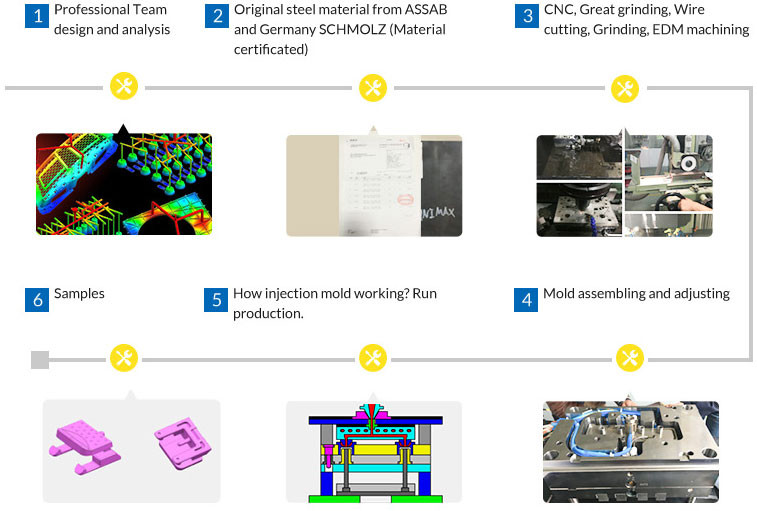

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

Product Flow

How to Customized a Mold?

A) Before sales Service

- 24hour online consult

- Sample support

- Detailed technical 2d and 3d drawing design

- Free pick up at hotle/aitport to visit Feiya factory

- Qick and profession response on quotation and technial

B) Production period service

- Technical 2d and 3d drawing submit to double check details and discussion

- Quality inspection report submit

- Installation solution and maintenance instruction

C) After sales service

- Provide the usage advice and Guide, remote assistance

- 15 Years quality Guarantee

- Any quality problems replace freely

Our Partner

Mold Comparision

Related Keywords