Precision medical equipment plastic syringe injection mold

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25-30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Kunshan,China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,China |

Precision medical equipment plastic syringe injection mold

Plastic Mould adopts software such as PRO/E, UG and MASTERCAM for product structure design and mold structure design. In the process of mold making, we pay close attention to design review and strict on-site management. The supervisors who have more than ten years of experience in actual mold making are supervised on site, strictly in accordance with the mold drawing, so that the mold making is more formalized and productized; the mold materials are mainly from the best suppliers. The company provides to ensure the quality of the mold; the currently manufactured molds are directly exported to the United States and European in addition to their own production needs.

Mold 2D + 3D drawing Design:

|

Product name |

Custom precision medical equipment plastic syringe injection mold |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: SCHMOLZ: P20HH, 2738, 2083H,2343, 2344, etc. DIN: 1.2738,1.2083, 1.2343, 1.2344, 1.3343, etc. AISI: P20, H13, D2, D6, M2, etc. ASSAB: 718HH, Nimax, 8402, 8407, XW-10, XW-5, EM2, etc. Japanese: HPM2, NAK80, SKD61, SKS3, SKD11, DC53, SKH51, etc. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. 2.Cold Runner. |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 1. 300,000-500,000 shots for 1 year under normal use prodcedure for pre-hardness steel material. 2. 5.00,000 shots for 1 year under normal use prodcedure for heat treatment steel material. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

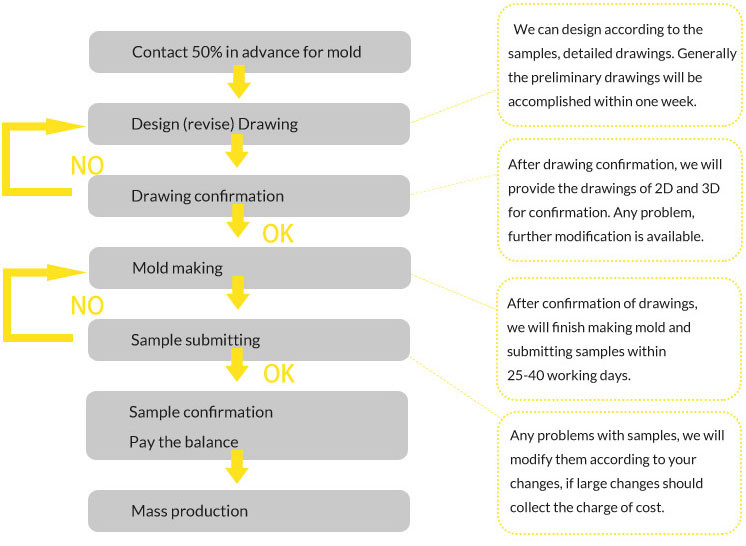

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

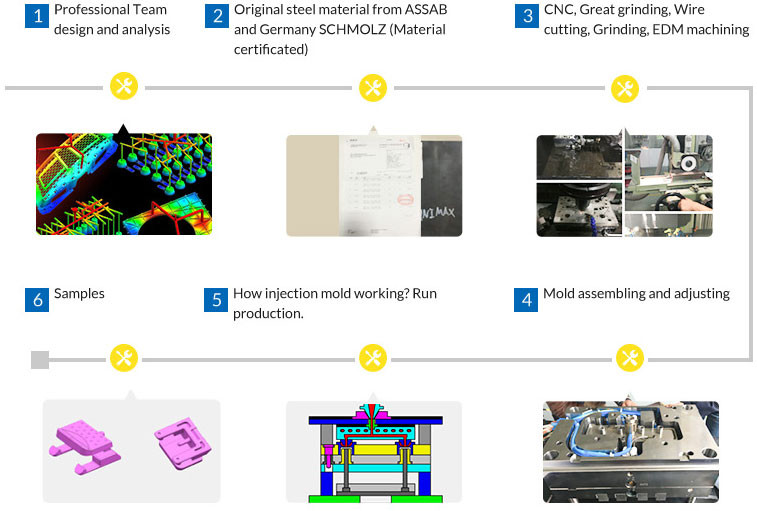

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

Product Flow

How to Customized a Mold?

A) Before sales Service

- 24hour online consult

- Sample support

- Detailed technical 2d and 3d drawing design

- Free pick up at hotle/aitport to visit Feiya factory

- Qick and profession response on quotation and technial

B) Production period service

- Technical 2d and 3d drawing submit to double check details and discussion

- Quality inspection report submit

- Installation solution and maintenance instruction

C) After sales service

- Provide the usage advice and Guide, remote assistance

- 15 Years quality Guarantee

- Any quality problems replace freely

Our Partner

Mold Comparision

Related Keywords