High Precision Plastic Injection Mould Making for Medcial With Moldflow

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Kunshan,China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,China |

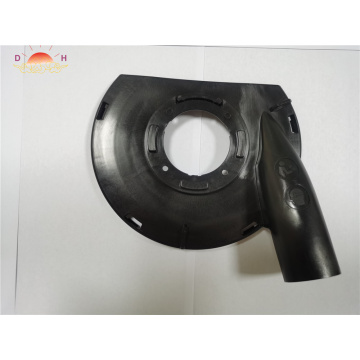

Precision pa66 plastic injection mould belt buckle mold

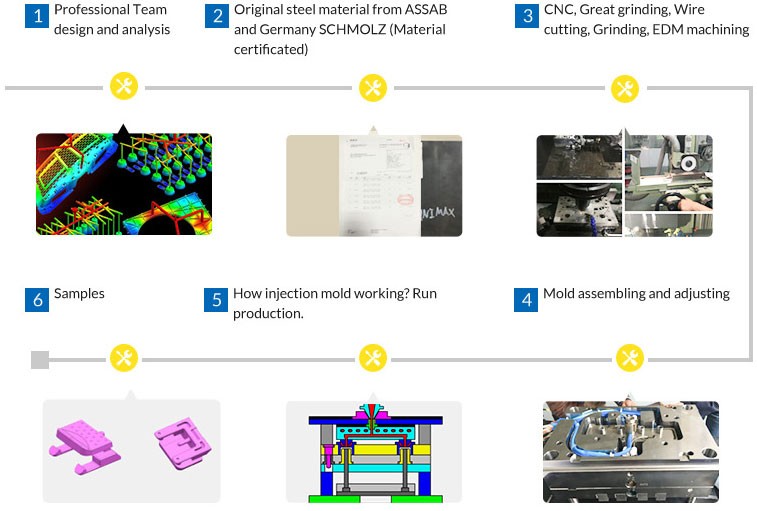

It is an injection molding method. The injection molding method has the advantage of production speed, high efficiency. It can realize automation operation, breed of design and the color is much, can shape by Jane to numerous. It can from big to small size, and precise in dimension and product upgrading. Can into complex shape parts. Injection molding is suitable for mass production with complex shape products and processing fields.

After a product is designed, usually by an industrial designer or an engineer. Molds are made by a mold maker (or toolmaker) from metal. Usually, either steel or aluminum and precision-machined to form the features of the desired part. Cost savings are highest when components have a minimum wall thickness. As long as that thickness is consistent with the part’s function and meets all mold filling considerations. As would be expected, parts cool faster with thin wall thicknesses. This means that cycle times are shorter, resulting in more parts per hour. Further, thin parts weigh less, using less plastic per part.

On average. The wall thickness of an injection molded part ranges from 2mm to 4mm (.080 inch to .160 inch). Thin wall injection molding can produce walls as thin as .05mm (.020 inch). Injection mold tooling is a very specialized profession requiring highly skilled engineers to create the injection mold tool.

|

Name |

high precision pa66 plastic injection mould belt buckle mold |

|

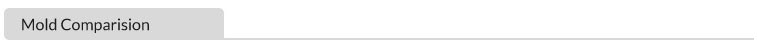

Mould material |

SKD11, ASP-23,SKH9, SKD61,P20,NAK80,8402,8407 |

|

Mould base |

LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

|

Material main core and cavity insert |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61 |

|

Cavity |

Single / Multi per request |

|

Runner |

Hot / Cold |

|

Mould life |

300,000-500,0000shots |

|

Maximum mould size |

1500*1500 mm |

|

surface request |

EDM & High Polish |

|

Design software |

UG,PROE,CAD etc. |

|

File Formats |

2D--dxf & dwg & pdf; 3D--UG files: like STP, IGS, X_T., Prt. |

|

Plastic material |

PP,PC,PE,ABS,PVC etc. |

|

Plastic products |

Electronic: Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards,USB housing. Automotive interior parts: connector, navigation frame, car key. All kinds of connectors, digital parts. |

|

Lead time |

plastic belt buckle mold 20-60days |

|

Specification |

Depends on customer’s requirements |

|

Payment terms |

T/T, L/C,Paypal, Western Union |

|

Trade terms |

FOB Shanghai,CIF |

|

MOQ |

plastic belt buckle mold can be 1 set |

|

Injection machine type |

High speed machine,80T,120T,150T,200T,250T,350T,500T,800T |

|

Package |

plastic belt buckle mold Wooden/Plywood case for tool ,PE bags add export carton for parts |

|

Value-added service |

Polish,texture,painting,screen printing,turnkey project |

Related Keywords