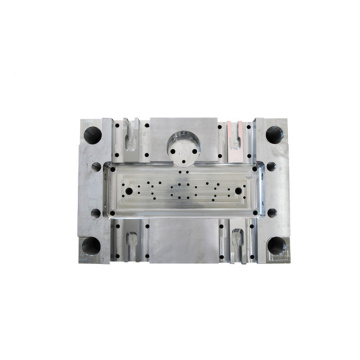

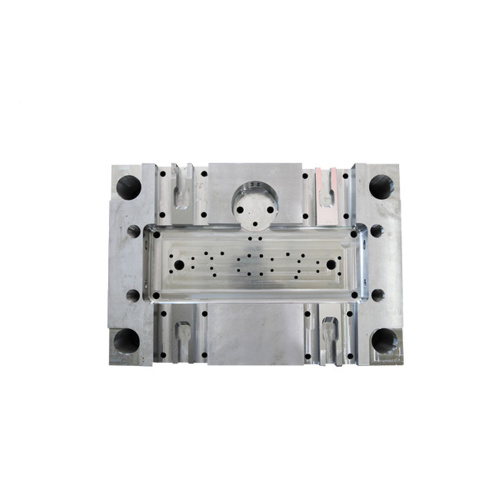

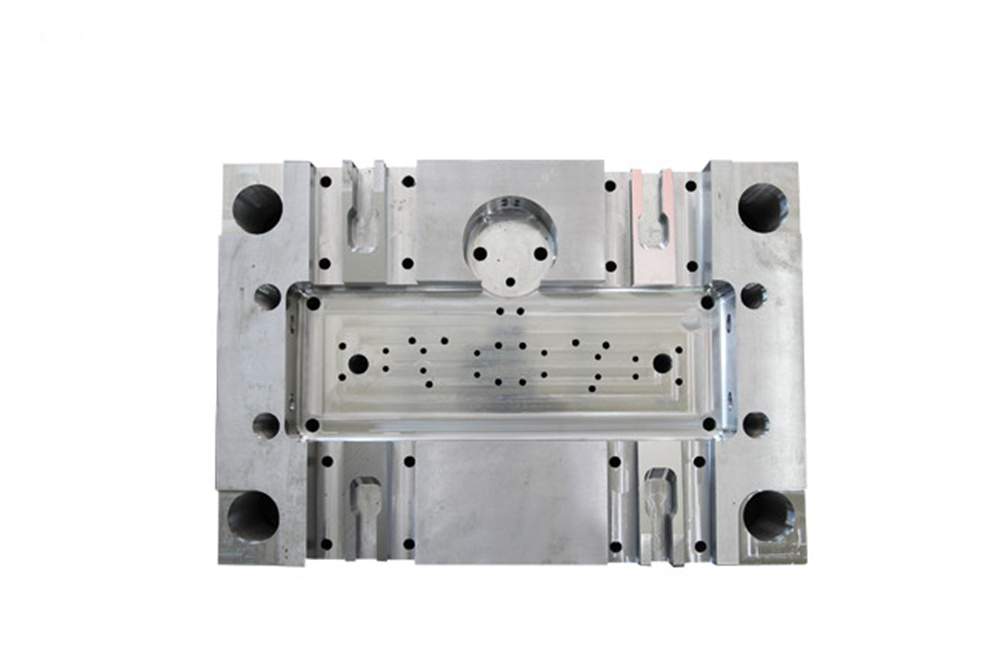

Professional Die-casting die mold base

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25-30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Ningbo, China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Kunshan,China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Ningbo,China |

Professional Die-casting die mold base

Die casting, a method of mold filling for molten alloy in a high tension and high speed condition, meanwhile, make molten alloy cooling and consolidation forming.

Die casting process is able to manifest the technology of a die casting factory in a certain degree, and can combine essential productive factors that are the characteristics of die-casting machine, mould, casting, and die-casting alloy, etc. In addition, die casting process provides customers with die casting products that can satiate clients’ requirements with the minimum cost.

Formulate the right procedures of die casting process. That die carter’s dexterity and high quality in mold maintenance is quite essential for improving process efficiency, ensuring the quality of die pressed casting, lowering rejection rate, reducing mould failure, and prolong the life span of molding.

| Name | Custom high accuracy mould components of cnc machining made in china |

| Product material | SKD11/61,SKH-9,SKH51,CD650,KD20,1.2379,1.2083,Tungsten steel, etc.Or as customer's requests. |

| Processing methods | CNC milling and turning,Grinding,Wire-cutting process,EDM process,etc. |

| Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Stamping lathes,Wire-cutting machine,Milling/Grinding machine,Punching/Drilling machine,Ultrasonec cleaning machine,etc. |

|

Detection equipment |

Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc. |

|

surface treatment |

Plating,Painting,Powder coating,Anodization,Ball blasting |

|

Design software |

UG,PROE,CAD etc. |

|

Specification |

11 years machining parts processing experience;Precision tolerance less than 0.001mm;Depends on customer’s requirements. |

|

Delivery |

Normally shipping in 5-10 days after payment,or according to customer's requests. |

|

Payment terms |

T/T, L/C,Paypal, Western Union |

|

Package |

Inner packing with recycle plastic box and anticorrosive oil, outer with sponge and PE bags, or as customer's requirements. |

High precision progressive stamping die and plastic injection mould

A) Before sales Service

- 24hours online consult

- Sample support

- Detailed technical 2d and 3d drawing design

- Free pick up at hotel/aitport to visit Feiya factory

- Quickly and professional response on quotation and technology

B) Production period service

- Technical 2d and 3d drawing submit to double check details and discussion

- Quality inspection report submit,guarantee the accuracy

- Installation solution and maintenance instruction

C) After sales service

- Provide the usage advice and Guide, remote assistance

- 16 Years quality Guarantee

- Any quality problems replace freely

Related Products-Precision mold part

Related Keywords