2.5Ton Counterbalance Forklift 3~6m lift height

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Ningbo, Lianyungang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000PCS |

| Supply Ability: | 1000PCS |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DE |

| Certificate: | CE/ISO 9001 |

| HS Code: | 842710 |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Lianyungang |

1.5 Ton Electric Counterbalance Forklift to 3.5 Ton Electric Counterbalance Forklift are available. Electric Counter Balance Forklift is one of the most widely used stacking equipment like Electric Pallet Truck. With great gradeability and half-closed cabin, the forklift can be used both indoor and outdoor. Compared with ordinary diesel engine forklift, electric forklift is more environment friendly and saves more daily cost.

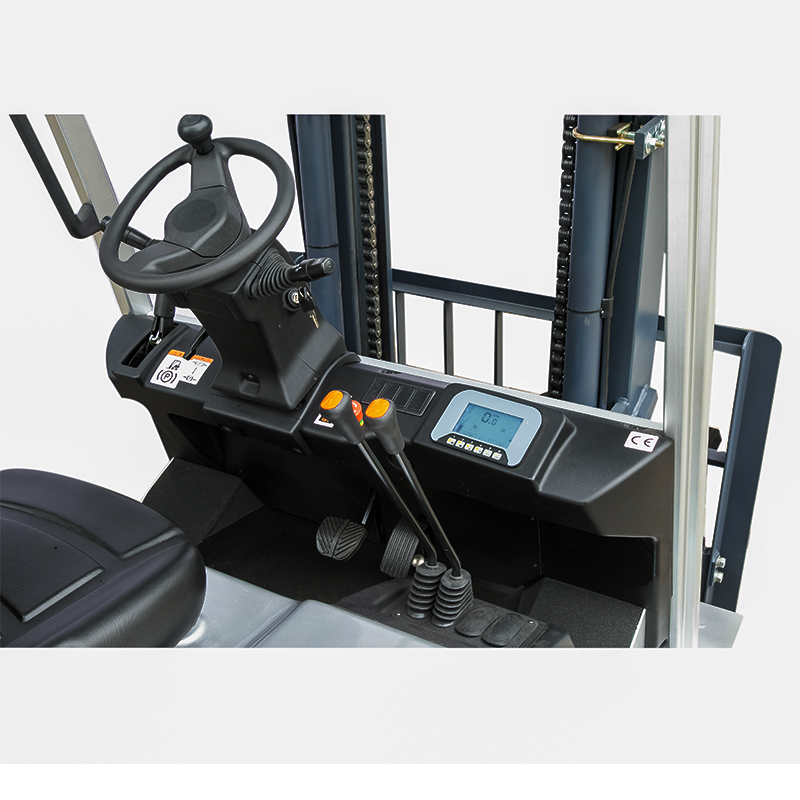

1. Pedal distributing of best angle

2. Larger gradeability

3. Cruising ability

4. Faster moving speed

5. High intensity overhead guard

6. High position steering node

7. Superior noise reduction technology

8. Fully AC system

9. The battery can be loaded and unloaded at the side so that the time of changing battery can be effectively reduced and the working efficiency can be improved, especially for the working condition with higher working intensity. There are optional batteries such as FAAM and GS.

10. 70% of the truck adopts molded components which can ensure the reliability of the whole truck.

The electric 4 wheel counterbalance forklift truck is equipped with a surrounding type seat which is an ergonomic design. It allows for waist adjustment and helps the operator maintain proper driving posture.

The gradeability can be up to 15%. The climbing speed can be up to 4km/h even when fully loaded.

The durable battery and improved performance and efficiency allocation can greatly increase the cruising ability of the forklift truck which means that the working period can be increased by 10%.

Fully loaded speed can be up to 14km/h.

The overhead guard is made of an irregular polygonal extruded material which delivers good compressive resistance and impact resistance in order to ensure the intensity of the overhead guard. Meanwhile, it can protect the driver from being hurt by falling materials.

The lateral moving is highly stable to reduce rollover.

The reasonable distribution and design of the noise reduction technology effectively quiets the forklift.

This truck has superior performance control. The motor is always maintenance free.

| Technical data | ||||||||||

| Manufacrurer | Zowell | |||||||||

| S.N | Description | Model | ||||||||

| FE20 | FE25 | FE30 | FE35 | |||||||

| Specification | 1.1 | Power Supply | Electric | Electric | Electric | Electric | ||||

| 1.2 | Operation type | Sitting on | Sitting on | Sitting on | Sitting on | |||||

| 1.3 | Rated load capacity | G | kg | 2000 | 2500 | 3000 | 3500 | |||

| 1.4 | Load center | C | mm | 500 | 500 | 500 | 500 | |||

| 1.5 | Front overhang | X | mm | 460 | 460 | 474 | 479 | |||

| 1.6 | Wheel Base | L1 | mm | 1520 | 1520 | 1620 | 1620 | |||

| 2.1 | Total weight | kg | 3700 | 4180 | 5100 | 5350 | ||||

| 2.2 | Axle | Load(Front/Rear) | kg | 5016/684 | 5920/760 | 7290/810 | 7965/885 | |||

| 2.3 | Unload(Front/Rear) | kg | 1628/2072 | 1780/2400 | 2450/2650 | 2420/2930 | ||||

| Tyres/Chassis | 3.1 | Tyres | Pneumatic | Pneumatic | Pneumatic | Pneumatic | ||||

| 3.2 | Tyres | Front Tyres | 23×9-10-16PR | 23×9-10-16PR | 23×9-10-16PR | 23×10-12 | ||||

| 3.3 | Rear tyres | 18×7-8-14PR | 18×7-8-14PR | 18×7-8-14PR | 18×7-8-14 | |||||

| 3.4 | Tyres quantity | Front tyres(x=Drive tyres) | 2x | 2x | 2x | 2x | ||||

| 3.5 | Rear tyres | 2 | 2 | 2 | 2 | |||||

| 3.6 | Front Wheel distance-Front | W1 | mm | 1039 | 1039 | 1039 | 1057 | |||

| 3.7 | Wheel distance-Rear | W2 | mm | 989 | 989 | 989 | 989 | |||

| Height | 4.1 | Tilting(Front/Rear) | α/β | Grad | 5/10 | 5/10 | 5/10 | 5/10 | ||

| 4.2 | Lifting height | H | mm | 3000 | 3000 | 3000 | 3000 | |||

| 4.3 | Free lift height | H1 | mm | 150 | 150 | 155 | 160 | |||

| 4.4 | Mast height | Mast closed | H2 | mm | 2055 | 2055 | 2055 | 2175 | ||

| 4.5 | Mast extended | H3 | mm | 3973 | 3973 | 4067 | 4072 | |||

| 4.6 | Overhead guard height | H4 | mm | 2140 | 2140 | 2140 | 2140 | |||

| 4.7 | Seat height | H5 | mm | 1100 | 1100 | 1100 | 1100 | |||

| 4.8 | Hitch pin height | H6 | mm | 290 | 290 | 290 | 290 | |||

| 4.9 | Overall length | With fork | L | mm | 3414 | 3414 | 3540 | 3545 | ||

| 4.10 | Without fork | L' | mm | 2344 | 2344 | 2470 | 2475 | |||

| 4.11 | Overall width | with Dashboard width | W | mm | 1265 | 1265 | 1265 | 1300 | ||

| 4.12 | Chassis width | W' | mm | 1190 | 1190 | 1190 | 1190 | |||

| 4.13 | Fork size(Length×width×thickness) | l×w×t | mm | 1070×120×40 | 1070×120×40 | 1070×125×45 | 1070×125×50 | |||

| 4.14 | Fork carriage standard | ISO2328 2A | ISO2328 2A | ISO2328 3A | ISO2328 3A | |||||

| 4.15 | Fork carriage width | W3 | mm | 1040 | 1040 | 1100 | 1100 | |||

| 4.16 | Fork width | Min | W4 | mm | 240 | 240 | 250 | 250 | ||

| 4.17 | Max | W5 | mm | 1040 | 1040 | 1100 | 1100 | |||

| 4.18 | Ground clearance | Mast | Unload/Load | H7 | mm | 125/110 | 125/110 | 125/110 | 125/110 | |

| 4.19 | Chassis width | Middle of Chassis | H8 | mm | 120 | 120 | 120 | 120 | ||

| 4.20 | Aisle width | 1000×1200 pallet horizontal ways | AST | mm | 3745 | 3745 | 3975 | 3980 | ||

| 4.21 | 800×1200 pallet horizontal ways | AST | mm | 3945 | 3945 | 4160 | 4165 | |||

| 4.22 | Turning Radidus | Min inside | Wa | mm | 2090 | 2090 | 2210 | 2210 | ||

| 4.23 | Min outside | r | mm | 110 | 110 | 110 | 110 | |||

| Performance | 5.1 | Max Drive speed(Unload) | km/h | 15 | 15 | 15 | 15 | |||

| 5.2 | Max Lift speed(Loaded) | mm/s | 250 | 250 | 250 | 250 | ||||

| 5.3 | Lowering speed(Load/Unload) | mm/s | ≤600 | ≤600 | ≤600 | ≤600 | ||||

| 5.4 | Gradeability(Load/unload) | % | 15 | 15 | 15 | 15 | ||||

| 5.5 | Max pulling force for hook(load) | N | 14000 | 18000 | 23000 | 23000 | ||||

| 5.6 | Braking type | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |||||

| 5.7 | Parking type | Mechanical | Mechanical | Mechanical | Mechanical | |||||

| Electric Parts | 6.1 | Driving motor | kW | 12AC | 12AC | 15AC | 15AC | |||

| 6.2 | Lifting motor | kW | 12AC | 12AC | 12AC | 12AC | ||||

| 6.3 | Battery voltage/capacity | V/Ah | 48/500 | 48/500 | 80/500 | 80/500 | ||||

| 6.4 | Battery weight | kg | 930 | 930 | 1510 | 1510 | ||||

| 6.5 | Battery box size(Length×width×height) | l×b×h | mm | 970×570×730 | 970×570×730 | 970×670×730 | 970×670×730 | |||

| 6.6 | Energy consumption | 5.0 | 5.8 | 6.5 | ||||||

| 6.7 | Min battery weight | kg | 740 | 740 | 1200 | 1200 | ||||

| 6.8 | Max battery weight | kg | 1075 | 1075 | 1550 | 1550 | ||||

| Others | 6.1 | Controller type | MOSFET/AC | MOSFET/AC | MOSFET/AC | MOSFET/AC | ||||

| 6.2 | Controller brand | ZAPI | ZAPI | ZAPI | ZAPI | |||||

| 6.3 | Controller model | ACE2 | ACE2 | ACE3+ACE2 | ACE3+ACE2 | |||||

| 6.4 | Hydraulic pressure | Mpa | 17.5 | 17.5 | 20 | 20 | ||||

| 6.6 | Noise | dB | 72 | 72 | 72 | 72 | ||||

| 6.8 | Hydraulic oil amount | liter | 28 | 28 | 38 |

38 |

||||

Related Keywords