Electric reach truck mini

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land

- Port:

- Shanghai, Ningbo, Lianyungang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000PCS |

| Supply Ability: | 1000PCS |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CIP |

| Certificate: | CE/ISO |

| HS Code: | 842710 |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo,Lianyungang |

Electric reach truck mini

Efficiency and safety are two values that industrial warehouse equipment manufacturers most cherised. Compared to pallet truck and towing tractor, the reach stacker has featured with reach and lifting function. Meanwhile, as one the advanced equipment of Zowell, FRC seated reach stacker provides excellent performance when working in confined space. Comfortable and smooth control are built from EPS and curtis electric control system in the whole process of material handling, lifting and reaching. With more effort paid in material handling, FRC is ready to save your cost as well as space in modern storage era.

Detail

features

1. Mini steering wheel

2. Multipath valve stem control

3. Suitable cushion

4. Adjustable auxiliary pedal

5. Operating mode

6. Superior gradeability

7. The fork can tilt

forward and backward for easy loading and unloading of goods and materials,

thus improving the transporting stability of the reach truck.

8. The gantry can move

forward and backward so that it can reduce turning radius of the truck as well

as ensuring running stability. The truck can be applied in various

environments.

9. EPS electronic steering

10. The overhead guard

with wide field of view can protect the operators from being hurt by falling

items.

11. USB

Technical Data

The turning of the steering wheel is smooth and comfortable. The operation can

be finished with only one hand by the operator. Drivers can carry out free

turning even in narrow spaces.

Different valve stems have different functions such as fork lifting/descending,

fork tilting forward/backward, gantry moving forward/backward. The distribution

of the valve stem is compact. The operator can carry out operation with only

one finger, realizing precise control without risk of input error.

The soft cushion can effectively relieve fatigue for the operators.

You can adjust the pedal according to your liking, thus improving comfort of

the operators.

You can freely choose either standing or sitting operating mode as soon as it

is suitable.

The powerful motor and 4 wheel truck structure can provide superior stability

and gradeability, so that the truck can deliver sufficient gradeability even

when it is fully loaded.

Compared with the traditional mechanical steering, EPS electronic steering help

the driver with turning by using electronic control device to produce auxiliary

power of relative level and direction according to the torque signal and speed

signal. So the operation of the driver can be more convenient and precise while

movement can be more stable and reliable.

The individual USB ports can be used to charge phones and other electronic

items.

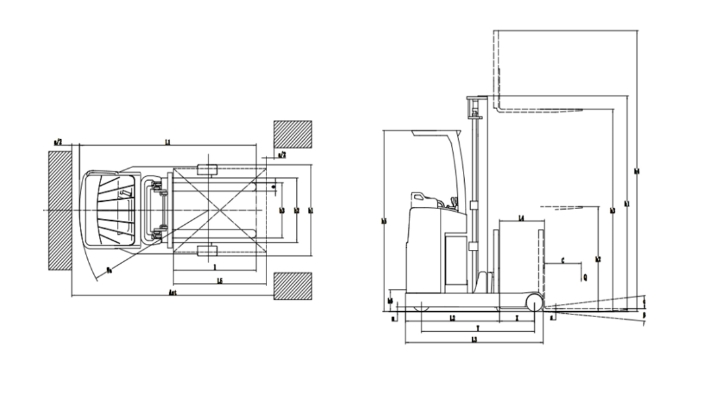

| FRC15 Electric Stacker | ||||

| Identification | 1 | Product Model | FRC15 | |

| 2 | Power supply | Electric | ||

| 3 | Driving type | Standing on/Sitting on | ||

| 4 | Rated Load capacity | Q kg | 1500 | |

| 5 | Load center | C mm | 600 | |

| 6 | Back overhang | X mm | 205 | |

| 7 | Wheelbase | Y mm | 1551 | |

| Weight | 1 | Self weight(Without battery) | kg | 1355 |

| 2 |

Axle loading, loaded drive end/load end |

kg | / | |

| 3 |

Axle loading, unloaded drive end/load end |

kg | 1062/543 | |

| Wheels | 1 | Wheels | mm | Polyurethane |

| 2 | Driving wheel size | mm | Φ230×80 | |

| 3 | Load wheel size | mm | Φ80×70 | |

| 4 | Balancing wheel size | mm | Φ125×50 | |

| 5 |

Wheels number (x=drive wheel) drive end/load end |

1x-2/4 | ||

| 6 | Tread width drive end | mm | 390 | |

| 7 | Tread width load end | mm | 551.5 | |

| Dimensions | 1 | Lowered mast height | h1 mm | See attached table |

| 2 | Free lift | h2 mm | ||

| 3 | Lifting height | h3 mm | ||

| 4 | Extended mast height | h4 mm | ||

| 5 | Fork height(lowerest) | h13 mm | 86 | |

| 6 | Overhead guard height | h6 mm | 2168 | |

| 7 | Over length | L1 mm | 2203 | |

| 8 | Length to face of forks | L2 mm | 1053 | |

| 9 | Over width | b1 mm | 920 | |

| 10 | Fork size | s/e/l mm | 180/66/1150 | |

| 11 | Fork width | b5 mm | 570 | |

| 12 | Min ground clearance | m2 mm | 30 | |

| 14 |

Aisle width for pallets,800X1200(fork along side 1200) a=200 |

Ast mm | 2594 | |

| 15 | Turning Radius | Wa mm | 1756 | |

| Performance | 1 | Travel speed loaded/unloaded | km/h | 6.5/7.5 |

| 2 | Lift speed loaded/unloaded | mm/s | 90/120 | |

| 3 | Lowering speed loaded/unloaded | mm/s | 125/80 | |

| 4 | Max gradeability loaded/unloaded | % | 5/8 | |

| 5 | Service brake | Electromagnetic | ||

| Electric Motor | 1 | Drive motor rating | kw | AC 2 |

| 2 | Lift motor rating | kw | 2.2 | |

| 3 | Battery voltage / nominal capacity | V/Ah | 24/280 | |

| 4 | Battery weight | kg | 250 | |

| Others | 1 | Type of drive control | MOSFET Control | |

| 2 | Noise level at operator's ear | dB(A) | <70 | |

| Model | Mast technical data | ||||

| Lifting height h3 | Total height(Mast lowerest)h1 | Total weight(mast extended) h4 | Free lift height h2 | ||

| CFE15 | Single mast | 1600 | 2010 | 2010 | 1600 |

| 1800 | 2210 | 2210 | 1800 | ||

| Double mast | 1800 | 1400 | 2265 | 0 | |

| 2200 | 1600 | 2665 | 0 | ||

| 2500 | 1750 | 2965 | 0 | ||

| 2700 | 1850 | 3165 | 0 | ||

| 3000 | 2000 | 3465 | 0 | ||

| 3300 | 2150 | 3765 | 0 | ||

| 3500 | 2250 | 3965 | 0 | ||

| 3700 | 2400 | 4215 | 0 | ||

| 3800 | 2450 | 4315 | 0 | ||

| 4000 | 2550 | 4515 | 0 | ||

| Triple Mast | 3500 | 1735 | 4005 | 1236 | |

| 4000 | 1905 | 4515 | 1396 | ||

| 4200 | 1965 | 4695 | 1476 | ||

| 4500 | 2065 | 4995 | 1576 | ||

| 4800 | 2165 | 5295 | 1676 | ||

| 5000 | 2225 | 5475 | 1756 | ||

Related Keywords