ASTM A179 Heat Exchanger Tube

-

USD1000≥1 Ton

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Ton

- Min. Order:

- 1 Ton

- Delivery Time:

- 45 Days

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 2000ton/month |

| Supply Ability: | 2000ton/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO,BV,TUV,SGS |

| HS Code: | 73043190 |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Heat exchanger tubes are used for cooling, heating or re-heating of gases or fluids in a wide range of industries like ( petro-)chemical, power generation, pharmaceutical and nuclear industry.

Unidus is leading manufacturer, supplier and expoerter of seamless heat exchanger tubes / condenser tubes in highest quality.

Thanks to our in-house bending facility, we can supply our heat exchanger / condenser tubes as U tube with quick delivery and cost-effective rates. Here you get more information on U-tubes

We can offer a wide range of grades and sizes.

Dimensions of heat exchanger tubes:

Outer Diameter(OD) : 0.5″~3″(12.7mm~76.2mm)

Wall Thickness(WT) :0.035″~0.3″(0.89mm~7.62mm)

Lengths and fixed lengths on request

Carbon & Alloy Steel

Standards

ASTM A 179

ASTM A 192

ASTM A 199

ASTM A 209

ASTM A 210

ASTM A 213

ASTM A 334

Carbon & Alloy Steel Grades

|

Carbon & Alloy Steel Grades |

||||||

|

ASTM-Grade |

|

UNS No. |

|

EN / DIN |

|

Material Code |

|

T1 |

|

|

|

|

|

X11CrMo5+NT1 |

|

T5 |

|

|

X11CrMo9-1+1 |

|||

|

T9 |

|

|

10CrMo5-5 |

|||

|

T11 |

|

|

13CrMo4-5 |

|||

|

T12 |

|

|

10CrMo9-10 |

|||

|

T22 |

|

|

|

|||

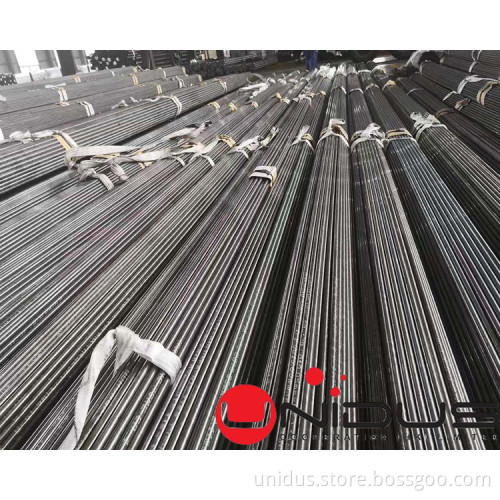

Packaging of heat exchanger tubes

(a) tubes bound with a steel band that has a paper underneath

(b) tubes wrapped in plastic sheets, burlap,

(c) tubes in wooden crates.

The tubes are supplied in packages with a circular or hexagonal outline with having weight of 300 – 2500 kg.

Testing of heat exchanger tubes

– prescribed mechanical tests,

– leak tightness test by eddy current,

– hydrostatic testing,

– ultrasound testing.

Certified test reports for heat exchanger tubes

ASTM / ASME A450

EN 10204: for EN 10297 non specified testing (only the mandatory tests), 2.2

specified testing – 3.1.B

after agreement – 3.1.A, 3.1.C, 3.2

DIN 50049, – 2.2, 3.1. B

Straightness of heat exchanger tubes

Straightness deviation for the whole length of a tube L can not exceed value of 0.0015 x L. In conversion to the 1 meter length it can not exceed 3 mm.

Condition of delivery and surface of tubes

Tubes are supplied according to agreed standards. The cold drawn tubes after the final forming go through thermal processing in shielding gas – normalizing.

Surface protection of heat exchanger tubes

The inner and outer surface is protected by a light oil application. Upon request it may be protected with and easy removable oil application on the outer side. The tube ends may be enclosed by a plug

Related Keywords