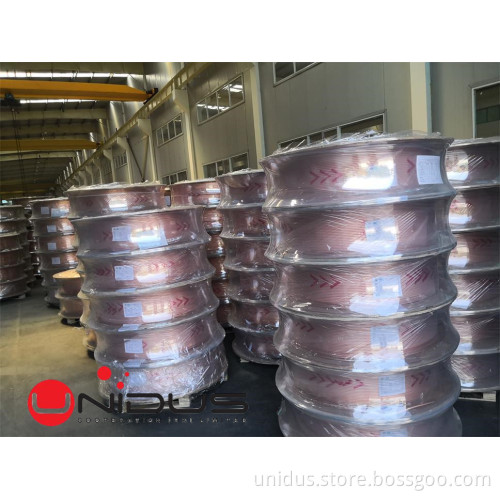

C12200 copper coil tubing

-

USD6000≥1 Ton

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Ton

- Min. Order:

- 1 Ton

- Delivery Time:

- 35 Days

- Transportation:

- Ocean, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000 ton /month |

| Supply Ability: | 1000 ton/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | TUV,BV,SGS |

| HS Code: | 74112200 |

| Transportation: | Ocean,Air |

| Port: | Shanghai |

Phosphorus-Deoxidized Copper Tubes – C12200 – are extensively used in sugar refineries for condensers and evaporators. Deoxidized copper is the standard material for transferring heat from steam to water or air because of their excellent resistance to corrosion by fresh water and their high thermal conductivities.

UNS No.

C12200 – BSI No. C107 – ISO Name Cu-DHP

Chemical Comp. (%)

Cu 99.9 / P 0.015N ~ 0.040

ASTM Spec.

B 75, B 111, B 395

ASME Spec.

SB 111, SB 395

Applications

Condenser, evaporator & heat exchanger tubes; Air conditioning & refrigeration; Plumbing pipes & steam tubes.

Temper

H55 Light Drawn / H80 Hard Drawn / O61 Annealed

Mechanical Properties:

Properties

Metric

Imperial

Density

8.94 g/cm³

0.323 lb/in³

Tensile Strength

221 ~ 379 MPa

32 ~ 55 ksi

Yield Strength

69 ~ 345 MPa

10 ~ 50 ksi

CTE, linear

17.7 10-6/°C @ 20.0 – 300 °C

9.8 10-6/°F @ 70.0 – 570 °F

Specific Heat Capacity

0.0920 cal/g-°C @ 20ºC

0.0920 BTU/lb-°F @ 70ºF

Thermal Conductivity

339 W/m-K @ 20.0 °C

196 BTU/ft2/ft/h/°F @ 70.0 °F

Melting Point

1083 °C

1981 °F

C23000-(Red Brass)

Normally used for pipe and pipe nipples. Excellent cold working properties: common fabrication processes include forming and bending, threading and knurling. Red Brass is the best quality pipe for general plumbing purposes It has high corrosion-resistance to water. Furnished in semi-annealed condition

C26000-(Cartridge Brass)

This alloy offers the best combination of strength and ductility of all copper-base alloys. Soft temper is widely used for severe cold working operations such as deep drawing and spinning, half hard for stamping and fight bending and forming, spring temper combines mild rigidity with good appearance

Typical uses include architectural. automotive, hardware, industrial and munitions. Excellent cold working properties.

C27200-(Yellow Brass)

Available in tube. Excellent cold working properties

C33000-(Low Leaded Brass) Available in tube. The addition of low amounts of lead allow for some degree of machinability, together with moderate cold working properties.

Phosphorus-Deoxidized Copper Tubes – C12200 – are extensively used in sugar refineries for condensers and evaporators. Deoxidized copper is the standard material for transferring heat from steam to water or air because of their excellent resistance to corrosion by fresh water and their high thermal conductivities.

| UNS No. | C12200 – BSI No. C107 – ISO Name Cu-DHP |

| Chemical Comp. (%) | Cu 99.9 / P 0.015N ~ 0.040 |

| ASTM Spec. | B 75, B 111, B 395 |

| ASME Spec. | SB 111, SB 395 |

| Applications | Condenser, evaporator & heat exchanger tubes; Air conditioning & refrigeration; Plumbing pipes & steam tubes. |

| Temper | H55 Light Drawn / H80 Hard Drawn / O61 Annealed |

Mechanical Properties:

| Properties | Metric | Imperial |

| Density | 8.94 g/cm³ | 0.323 lb/in³ |

| Tensile Strength | 221 ~ 379 MPa | 32 ~ 55 ksi |

| Yield Strength | 69 ~ 345 MPa | 10 ~ 50 ksi |

| CTE, linear | 17.7 10-6/°C @ 20.0 – 300 °C | 9.8 10-6/°F @ 70.0 – 570 °F |

| Specific Heat Capacity | 0.0920 cal/g-°C @ 20ºC | 0.0920 BTU/lb-°F @ 70ºF |

| Thermal Conductivity | 339 W/m-K @ 20.0 °C | 196 BTU/ft2/ft/h/°F @ 70.0 °F |

| Melting Point | 1083 °C | 1981 °F |

C23000-(Red Brass)

Normally used for pipe and pipe nipples. Excellent cold working properties: common fabrication processes include forming and bending, threading and knurling. Red Brass is the best quality pipe for general plumbing purposes It has high corrosion-resistance to water. Furnished in semi-annealed condition

C26000-(Cartridge Brass)

This alloy offers the best combination of strength and ductility of all copper-base alloys. Soft temper is widely used for severe cold working operations such as deep drawing and spinning, half hard for stamping and fight bending and forming, spring temper combines mild rigidity with good appearance

Typical uses include architectural. automotive, hardware, industrial and munitions. Excellent cold working properties.

C27200-(Yellow Brass)

Available in tube. Excellent cold working properties

C33000-(Low Leaded Brass) Available in tube. The addition of low amounts of lead allow for some degree of machinability, together with moderate cold working properties.

Related Keywords