Vertical Mill Parts Welding Recondition

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 500 tons per year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9001: 2015 |

| HS Code: | 8474900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Qingdao,Shenzhen |

Vertical Mill Parts Welding Recondition

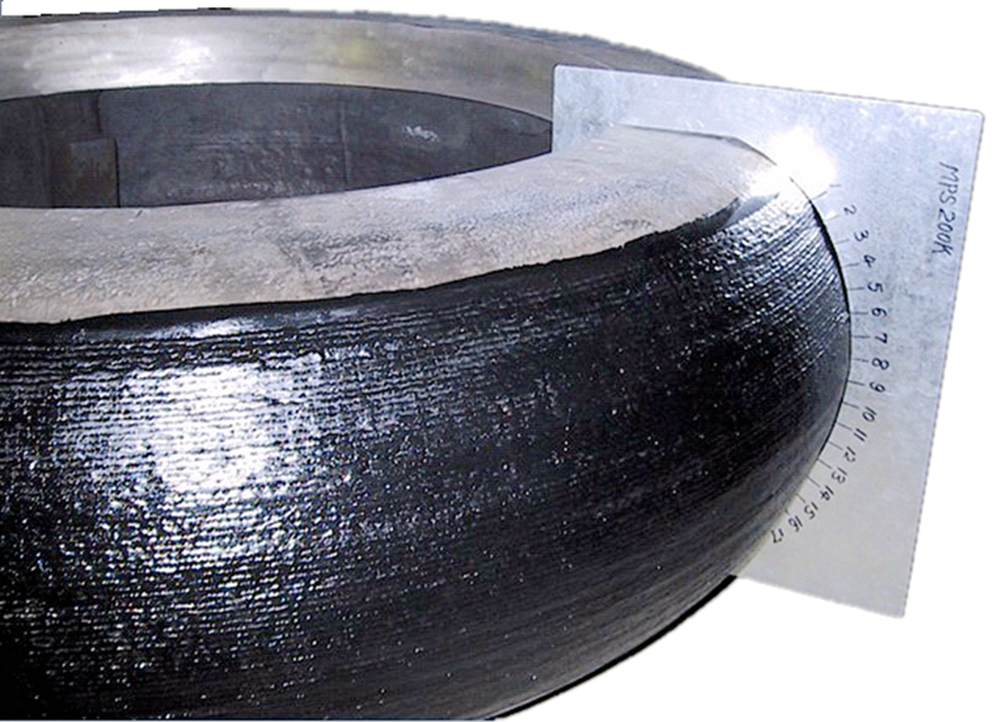

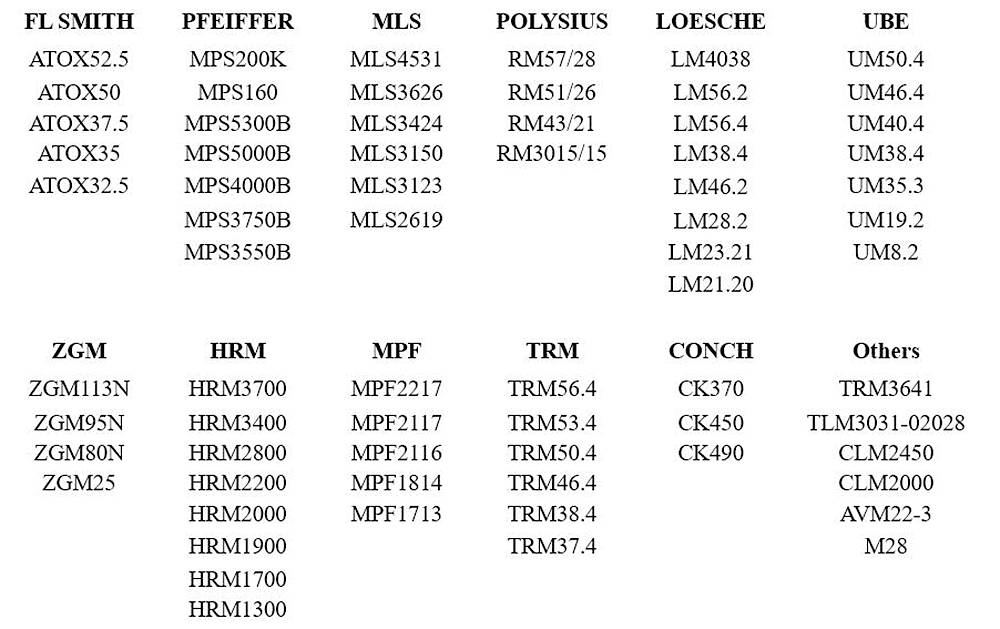

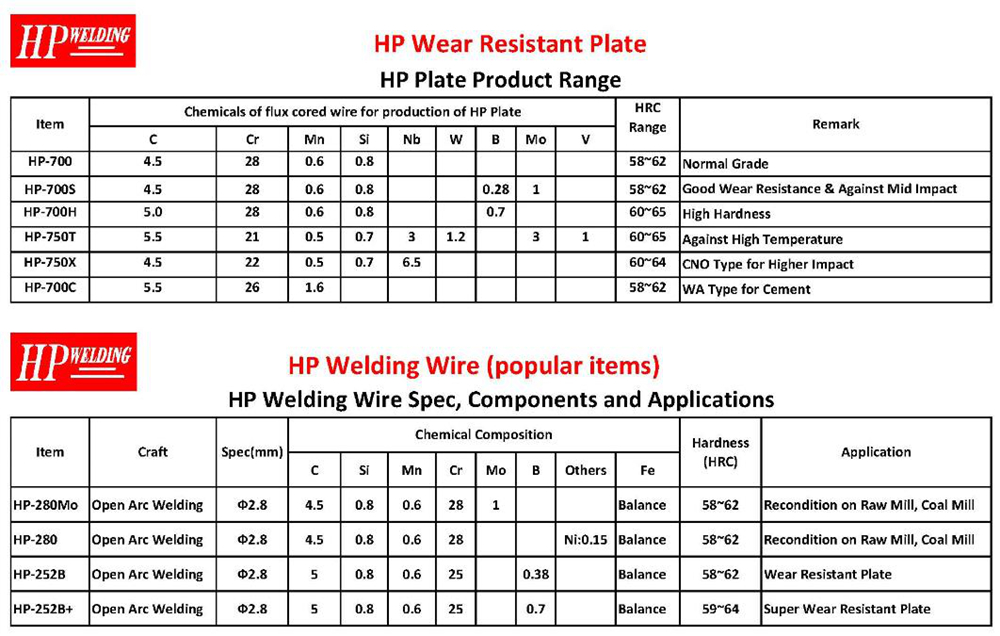

Welding Recondition is a highly technical operation that should be performed by professionals. With the experience gained from global welding service, we have developed our own unique program for wear protection on the various spare parts including Grinding Table Liner Welding Recondition, Wear Resistant Casting Spare Parts Welding Rebuild, Cement Mill Grinding Table Welding Rebuild, highly skilled technicians who respect our specific welding process with mature HP Flux Cored Welding Wire.

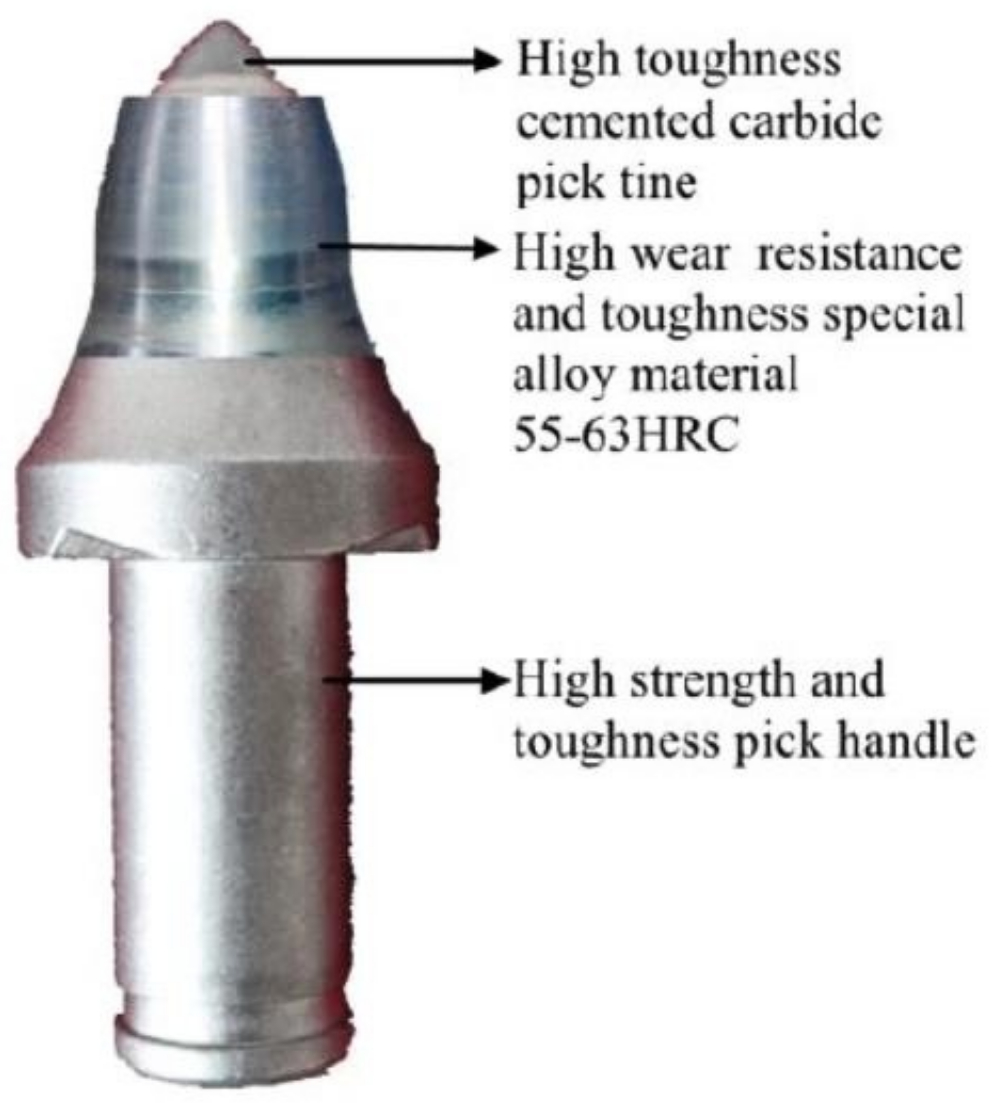

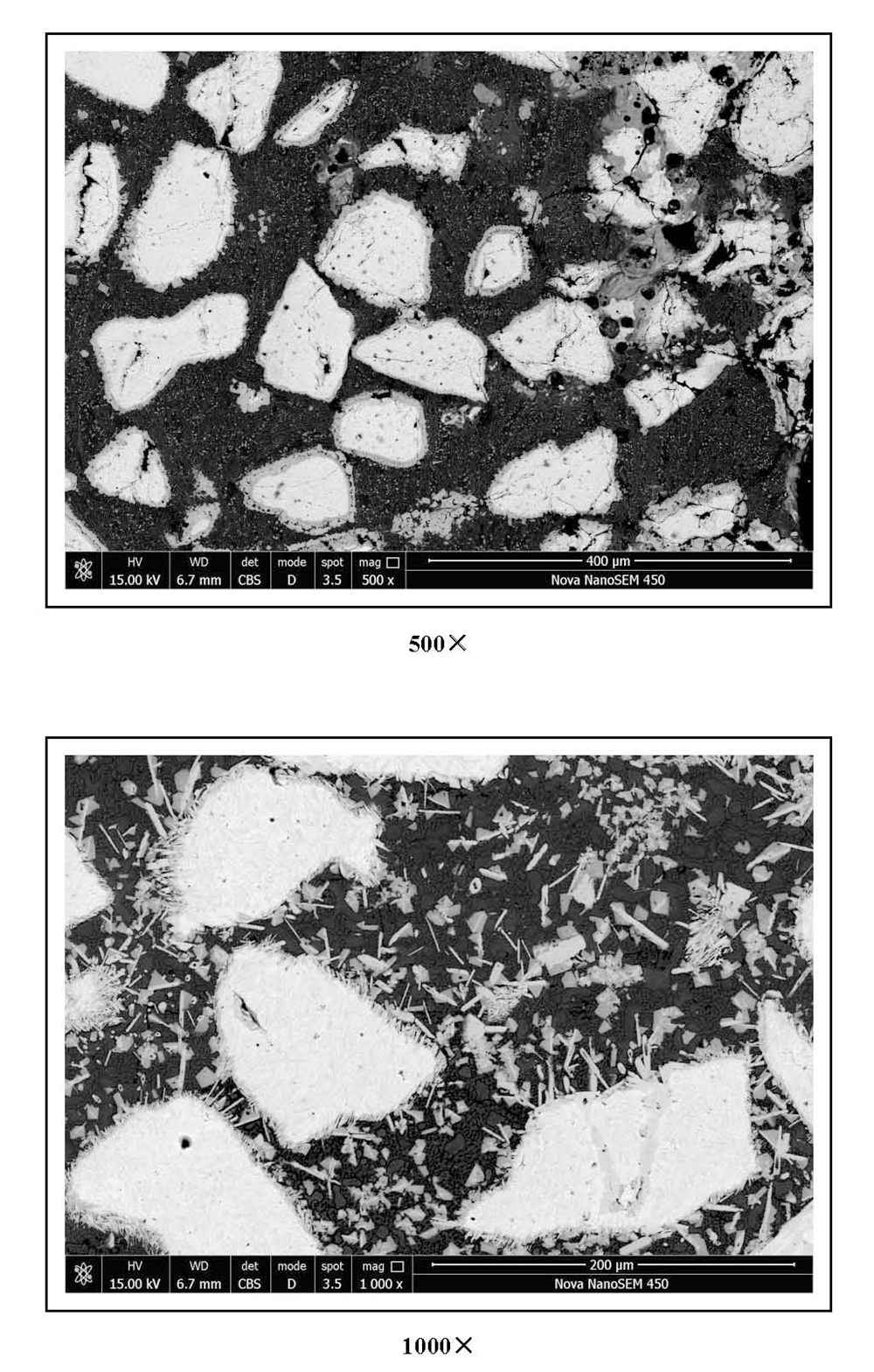

Metallographic Pictures of Tungsten Carbide Overlay By Plasma Transfer Welding

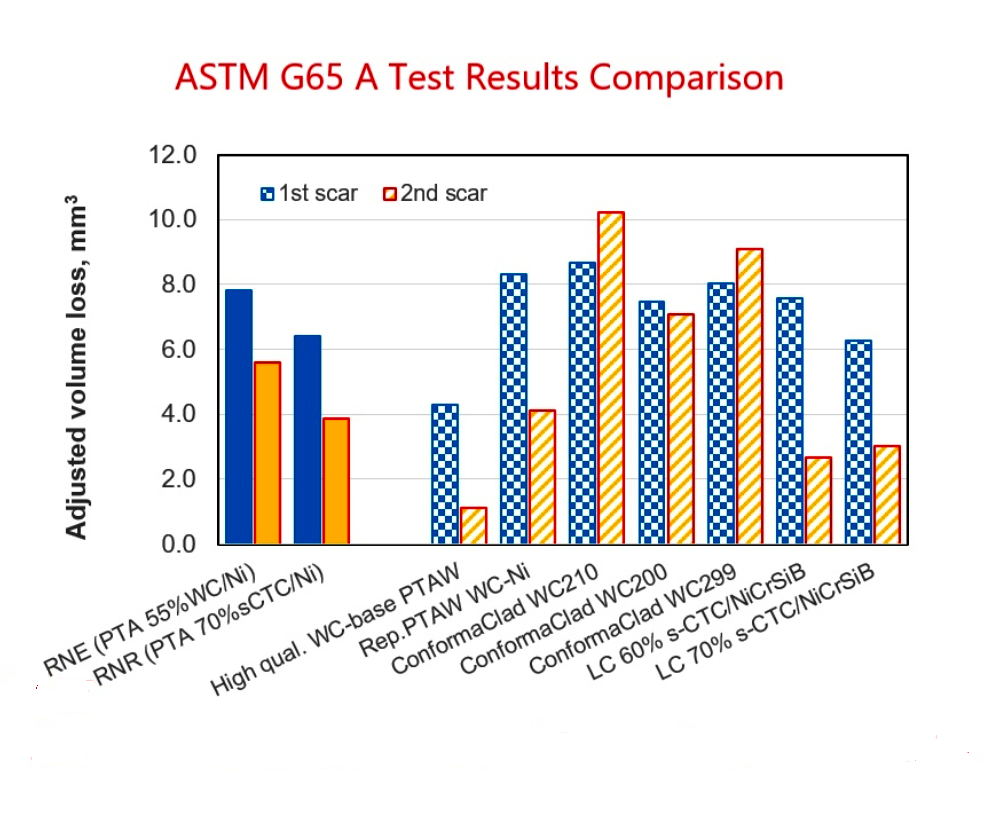

HP 750W products are developed for extremely abrasive applications and both the prime carbide and the matrix are very hard to be against abrasion. This grade is made from spherical tungsten carbide dispersed in NiCrBSi matrix by Plasma Transferred Arc Weld (PTAW) process. The tungsten carbide is 70-75 wt % and the particle size is in the range of 60-325 mesh (44-250 micron) with hardness HV 2700- 2900. The bulk hardness of NiCrBSi matrix is HRC 60-70.

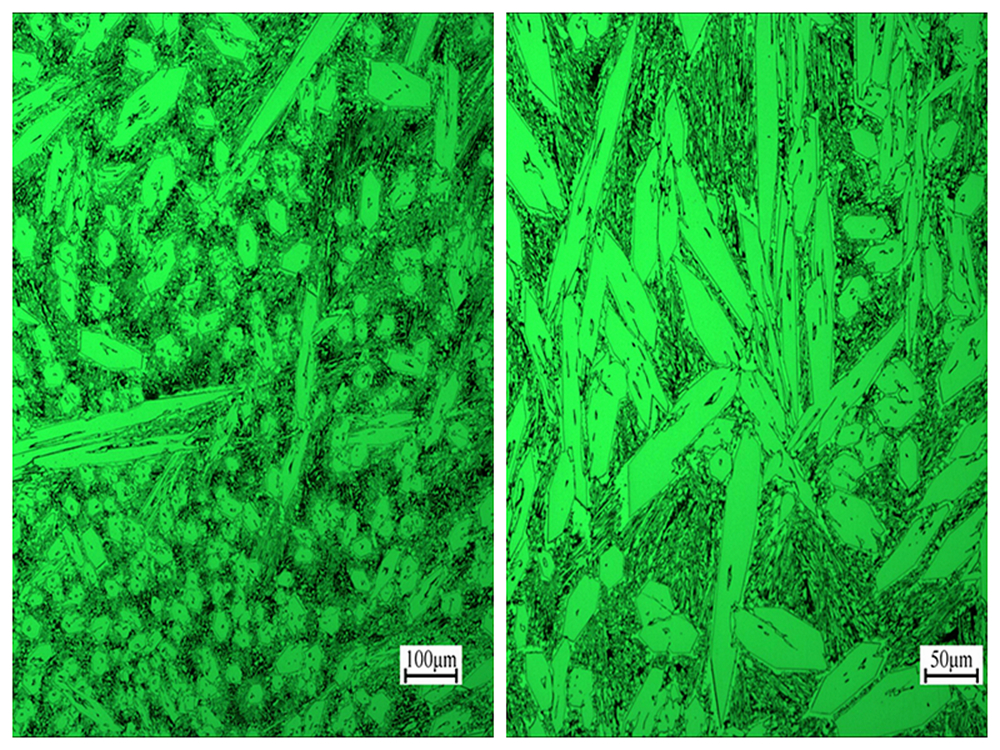

Metallographic Pictures of Chromium Carbide Overlay By Open Arc Welding

The vertical Mill spare parts_Rollers and Grinding Table Liners which are welding rebuilt by us have unique quenching properties through HP's independently designed wear resistant treatment process. The product not only has good wear resistance and high impact load, but also improves the grinding efficiency and increases the hourly capacity of the machine.

Laboratory Equipments Testing On Welding Rebuilt Product

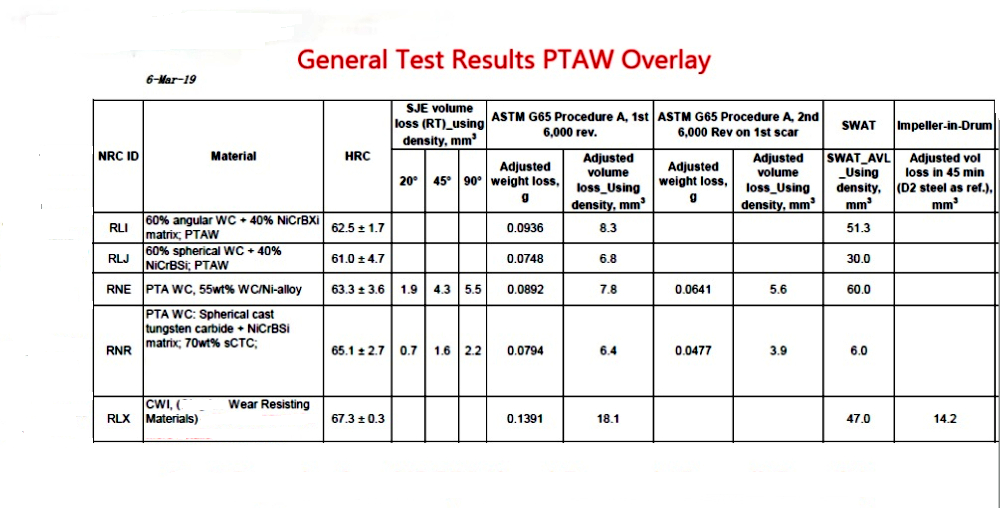

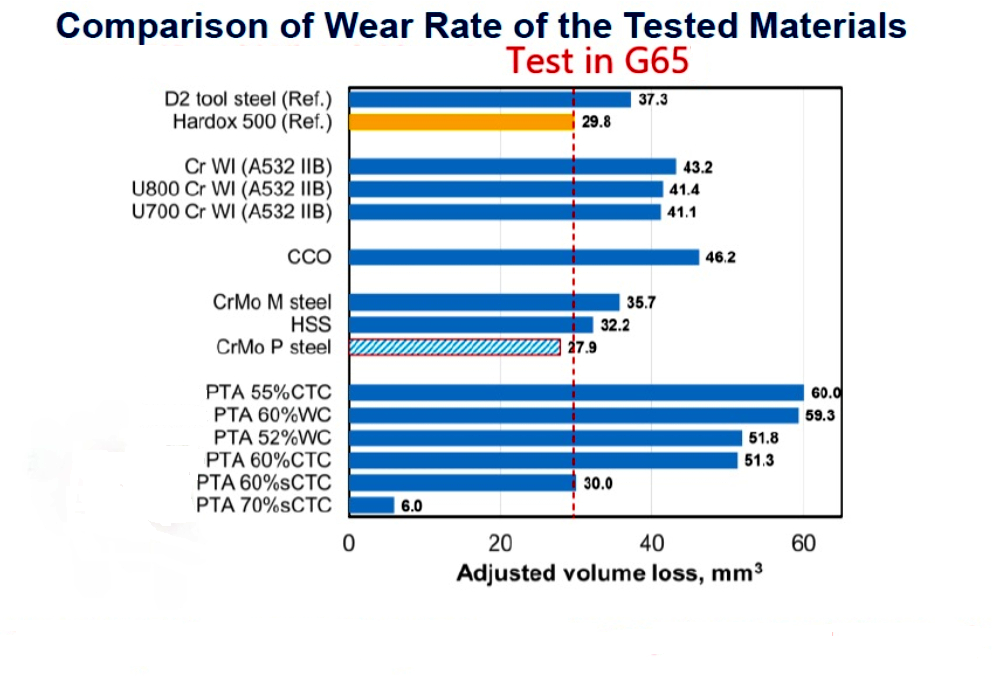

Test Reports On PTAW Products:

Packing & Delivery

Packing Way: By Steel Frame or Wooden Case

Delivery Time: 30 days or to discuss

FAQ On HP Welding Rebuilt Products

Question 1: What should be taken before welding rebuild?

Answer: Dye penetrate test on workpiece. This is the key operation to protect it from being ruptured during welding rebuild

Question 2: How many welding pass to be made with hardfacing overlay on workpiece?

Answer: Normally we get Bottom Build, Buffer Layer, Enhance Milddle & Top Hardfacing Surface, total 4 overlays are recommended.

Question 3: How much hard from the surface of welding rebuilt parts?

Answer: The hardness tested from surface could be HRC60±2.

Question 4: What is the warranty period of the rebuilt roller & grinding table of cement mill?

Answer: 2,000 hours guaranteed for slag and 8,000 hours for limestone in normal work condition.

Question 5: What kind of technology taken on welding rebuilt products?

Answer: Open arc welding and Plasma transfer alloy welding.

Related Keywords