Tungsten Carbide Clad Plate

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- S, h, a

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 500 tons per year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9001: 2015 |

| HS Code: | 72109000000 |

| Transportation: | Ocean,Land,Air |

| Port: | S,h,a |

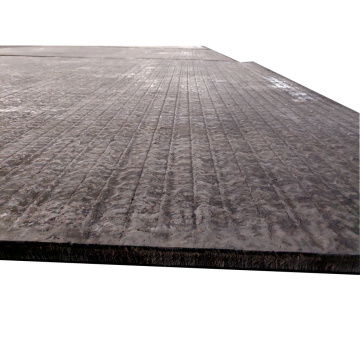

Tungsten Carbide Clad Plate

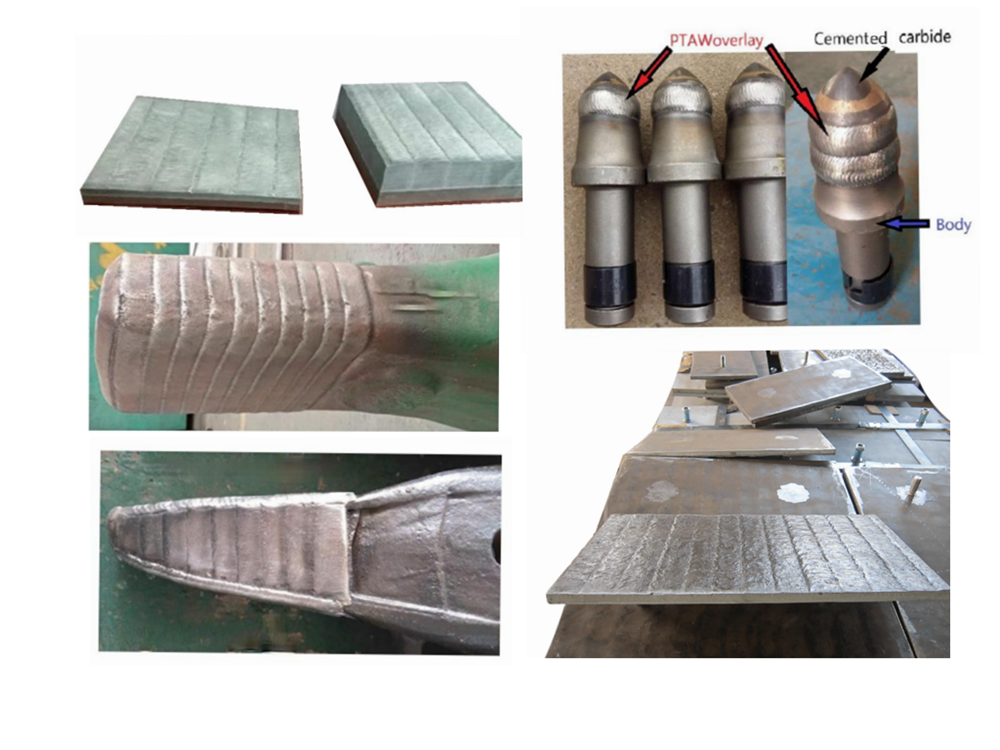

PTA is a true welding process, with deposits forming a metallurgical bond with the base metal.

The dilution level of wear plate by Plasma Transfer Welding is very close to those obtained by using the oxy-acetylene process.

A further advantage of using the PTA process is the capability of producing thin edge surfaces.

HP supply such grade steel sheet including Tungsten Carbide Steel Plate,Wear Resistant Steel Plates, PTA W Alloy Steel Plate, Clad Abrasion Steel Plate

Quick View On Product

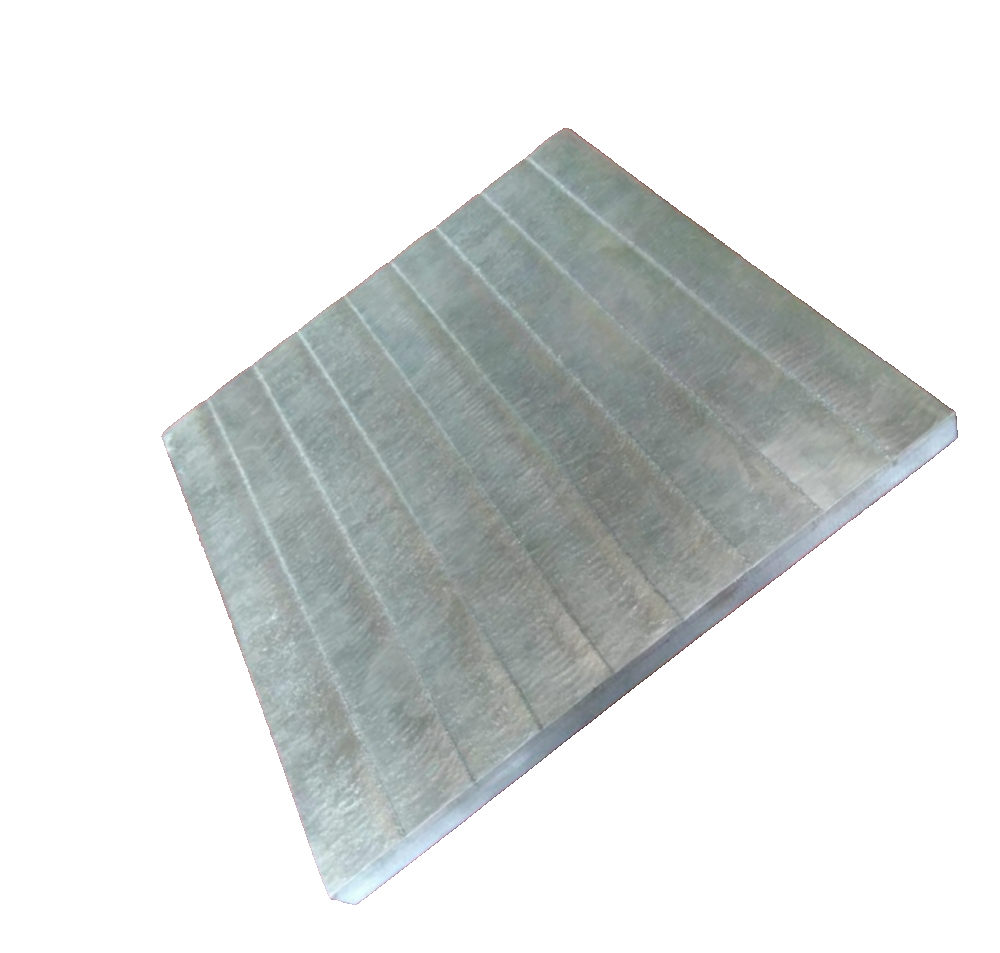

1. Product Name: Tungsten Carbide Steel Plate

2. Body Material: A36 Mild Steel + Tungsten Carbide Overlay (Hardfacing)

3. Grade: HP750W

4. Standard Size: 1000*2000mm; 1000*3000mm or Customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

6. Applications: Mining, Metallurgy, Cement, Railway, Road, Power Generation, Military & Others

7. Certification: ISO9001, SGS, CTI, ROHS

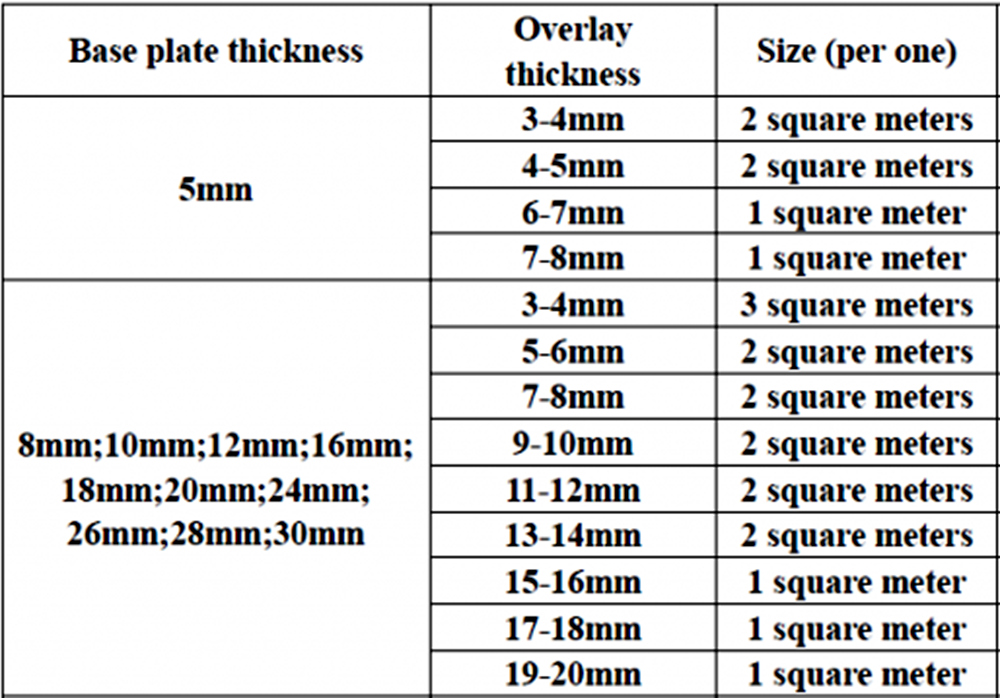

Standard Specifications of HP-750W WCO Plates:

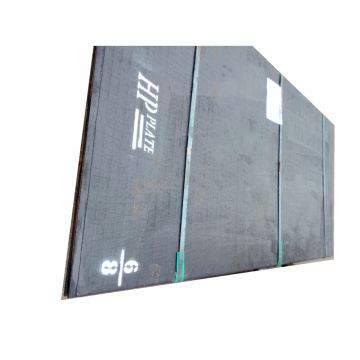

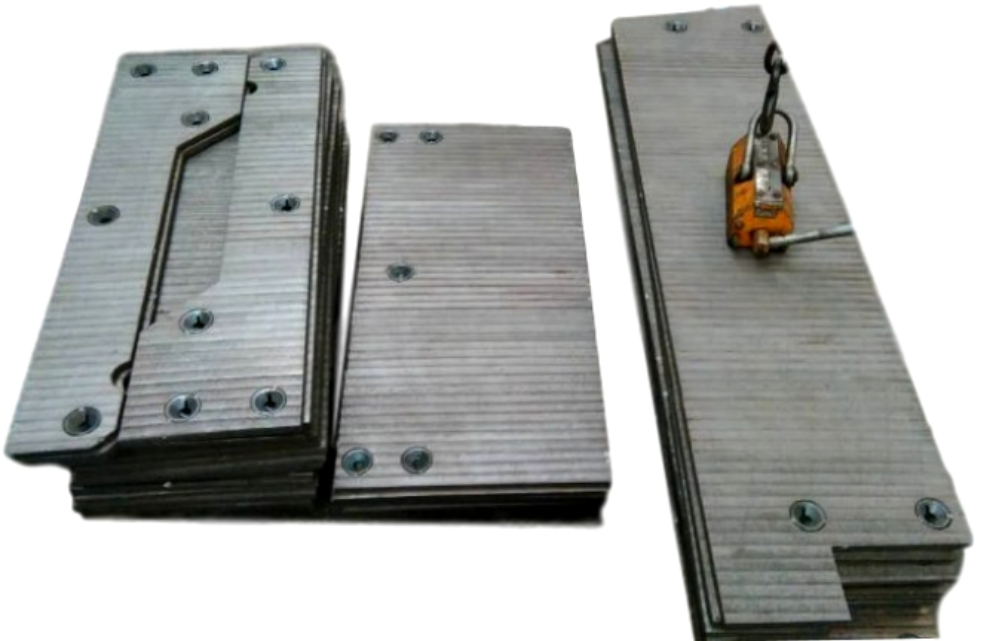

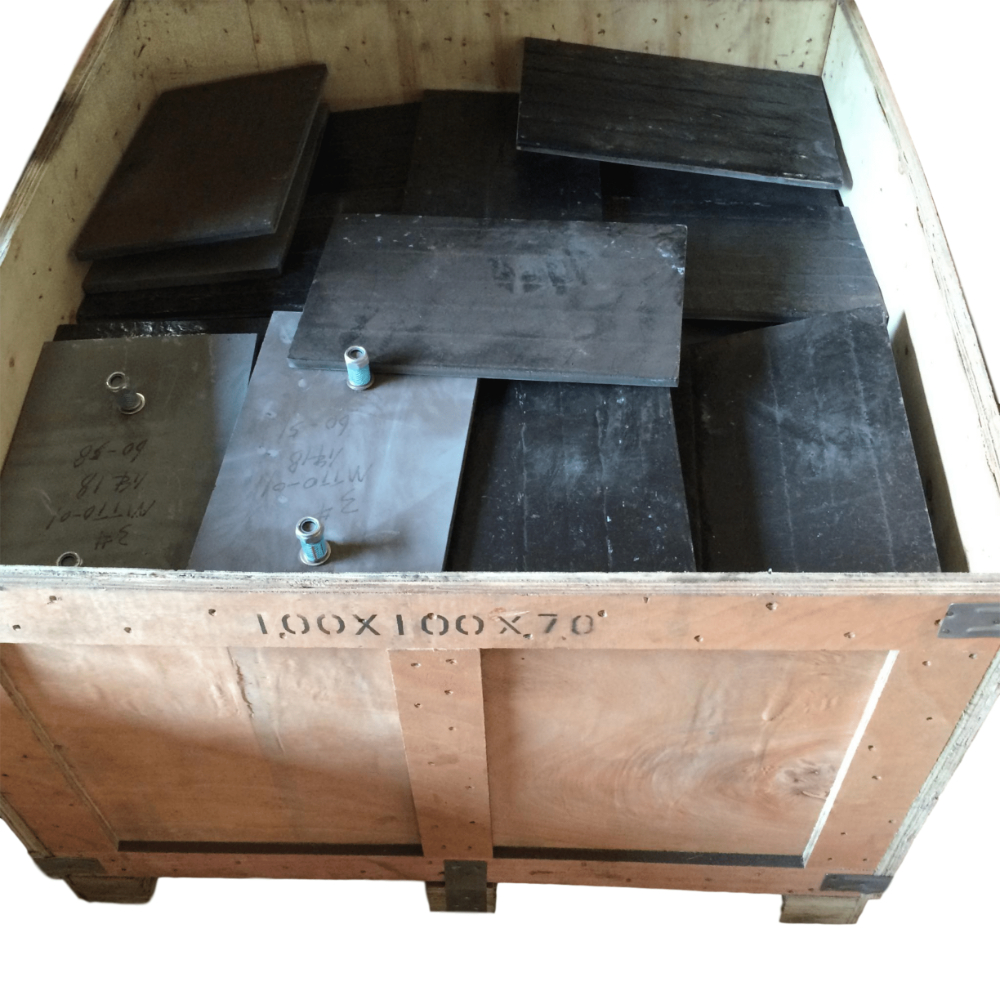

Packing & Delivery of Wear Plate

Packing Way: By Wood Case

Delivery Time: 30 days after order confirmation

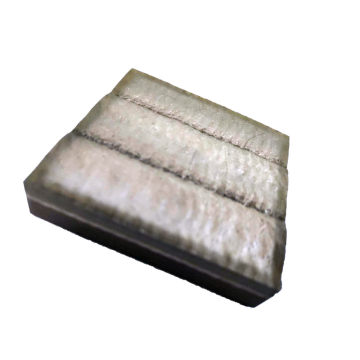

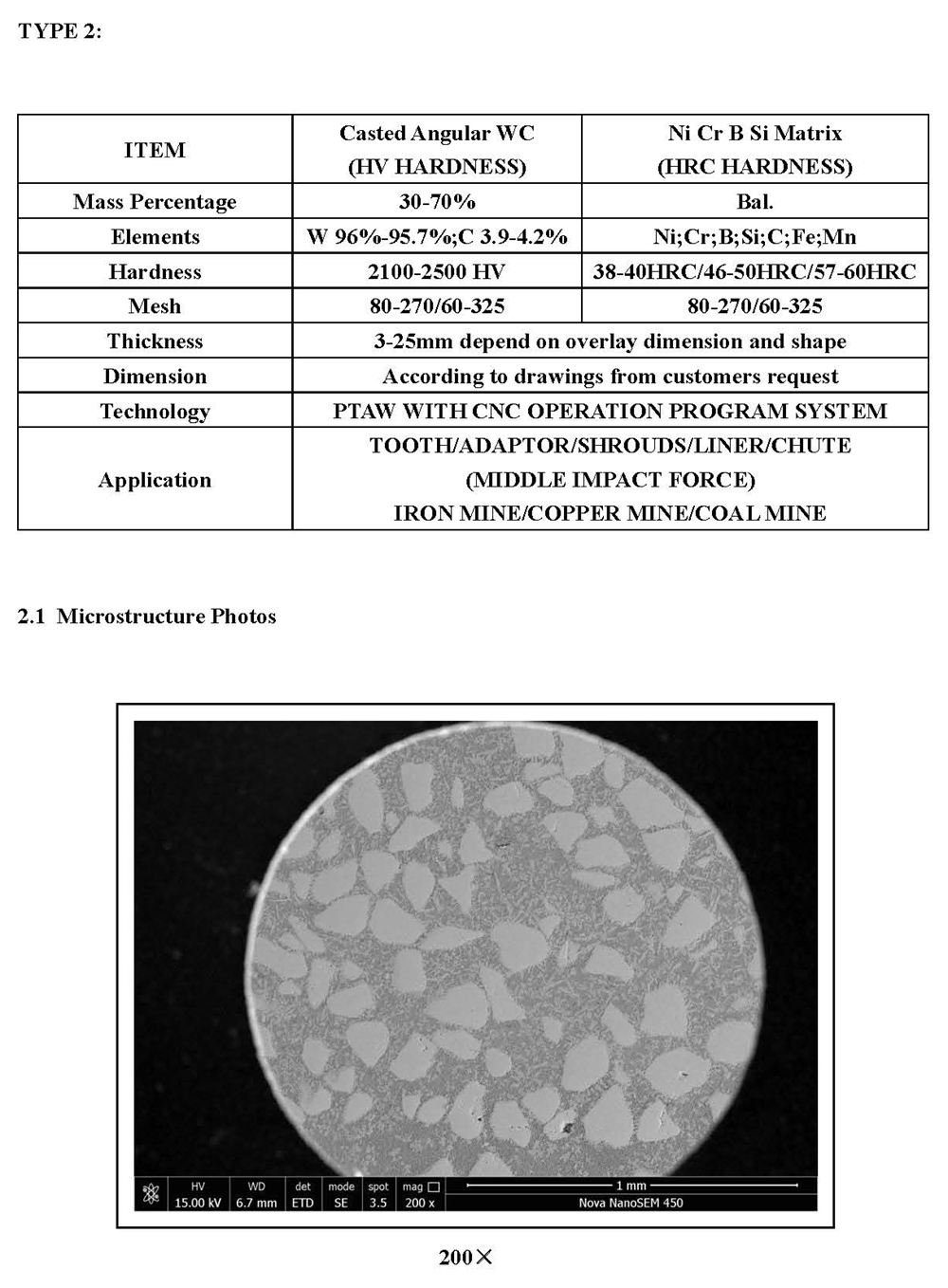

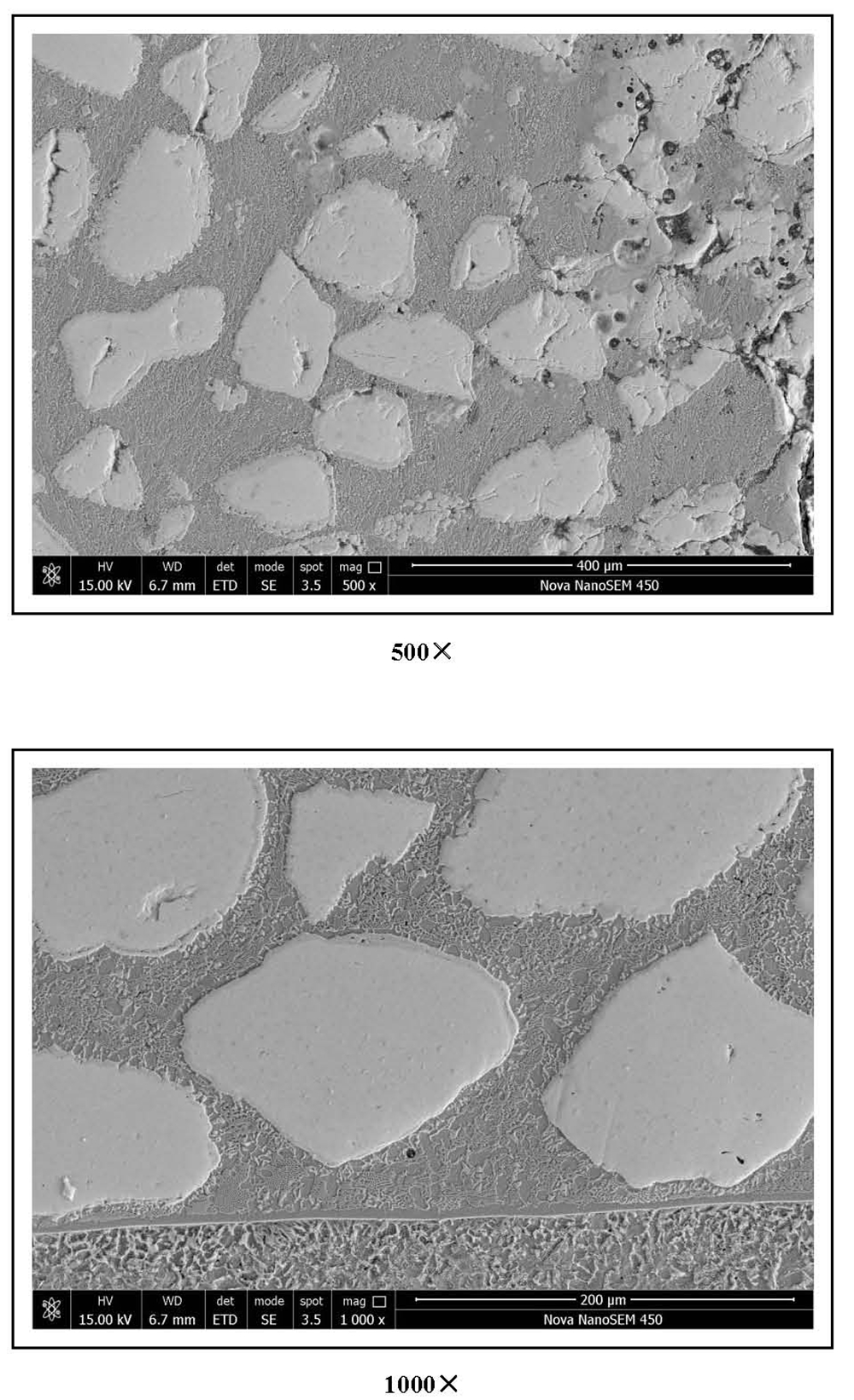

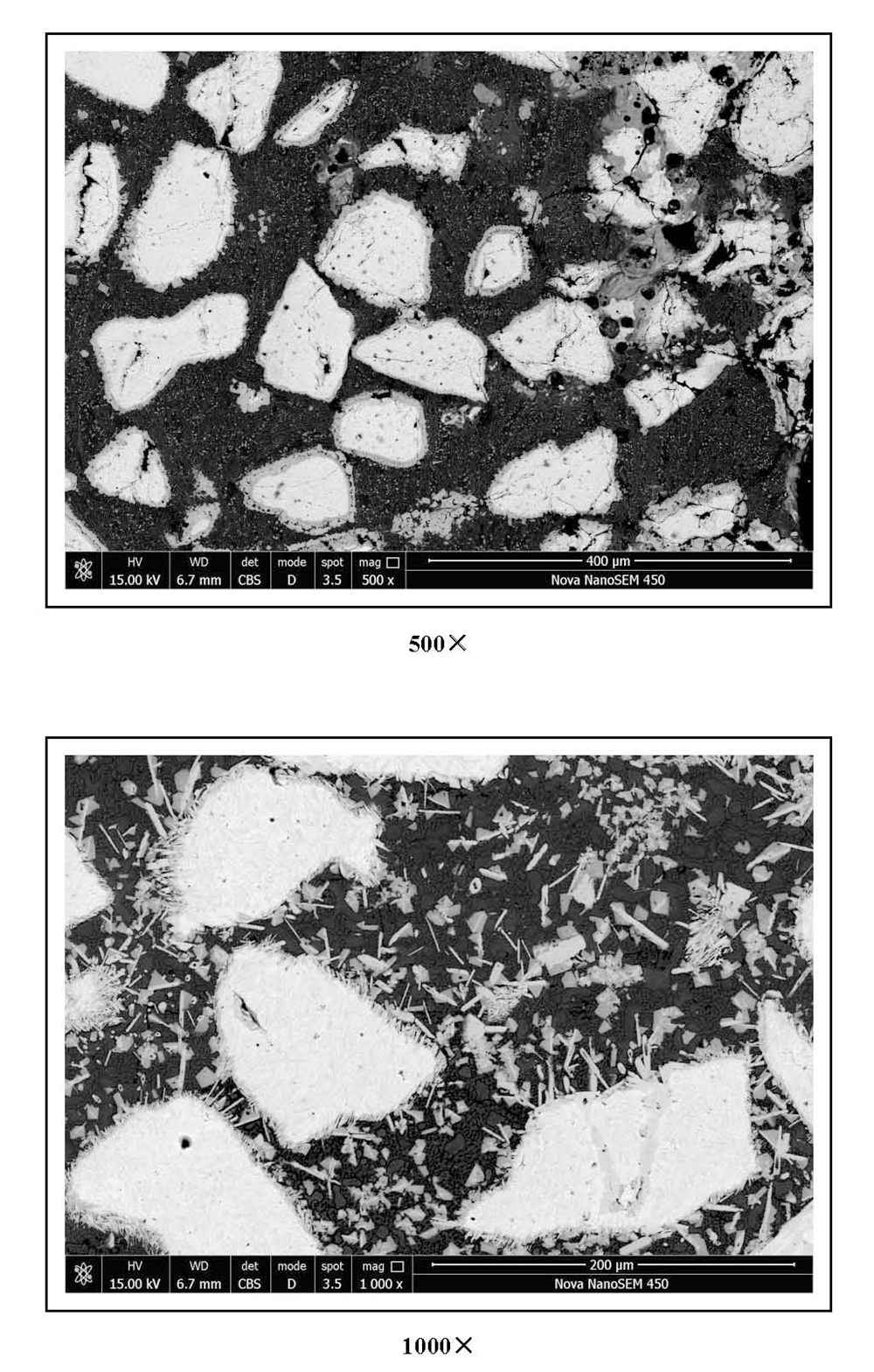

Metallographic Pictures of Tungsten Carbide Overlay Plate

Intrduction On Plasma Transferred Arc Weld (PTAW) Products

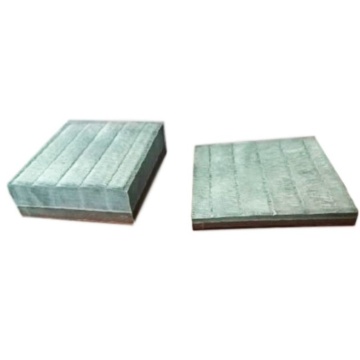

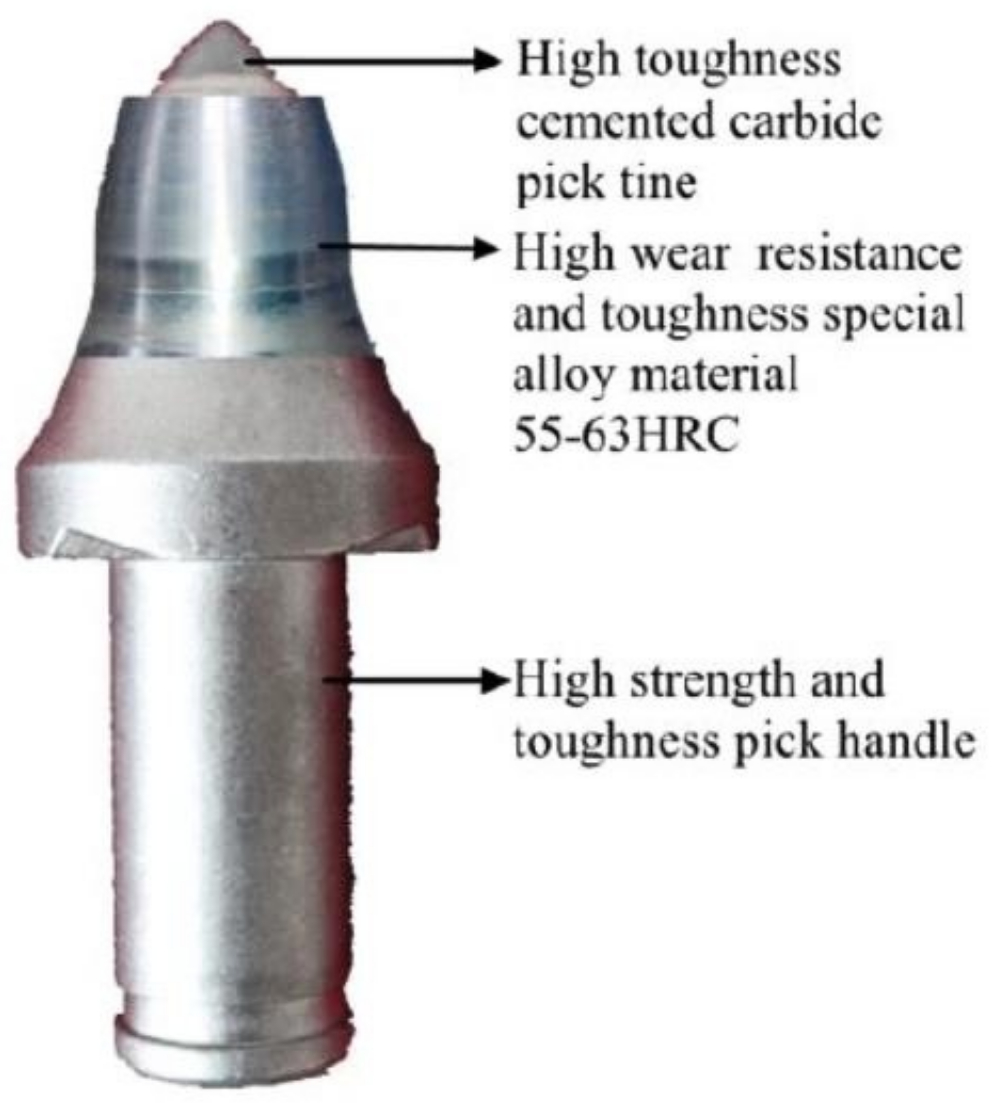

HP 750W products are developed for extremely abrasive applications and both the prime carbide and the matrix are very hard to be against abrasion.

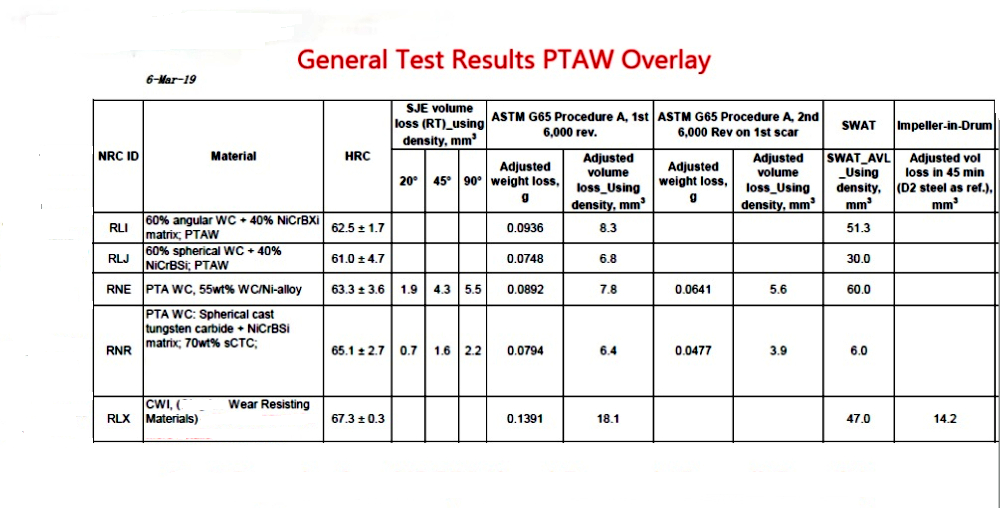

This grade is made from spherical tungsten carbide dispersed in NiCrBSi matrix by Plasma Transferred Arc Weld (PTAW) process. The tungsten carbide is 70-75 wt % and the particle size is in the range of 60-325 mesh (44-250 micron) with hardness HV 2700- 2900. The bulk hardness of NiCrBSi matrix is HRC 60-70.

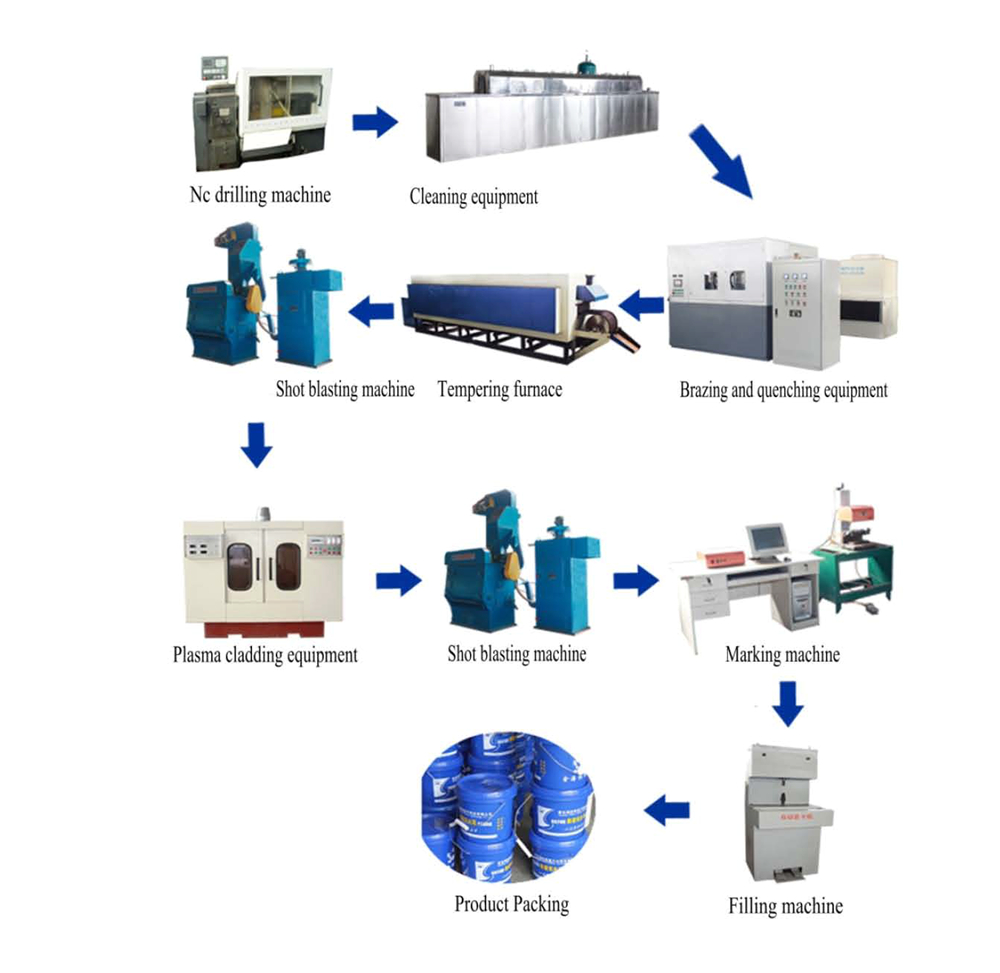

PTAW Production Procedure

Forging body---CNC drilling---Brazing and quenching---Tempering---Shot blasting---PTAW overlay welding---Shot blasting---Marking---Install clamp spring---Package

PTAW Production Equipment

Plasma Transfer Arc Welding (PTAW) Product Range:

Laboratory Equipments On PTAW Product

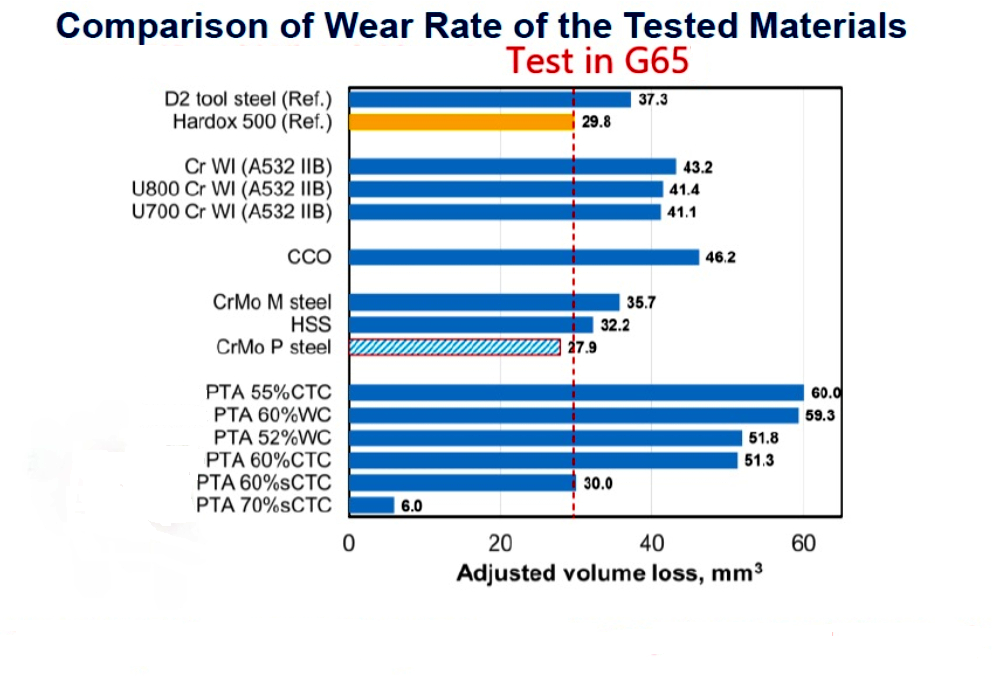

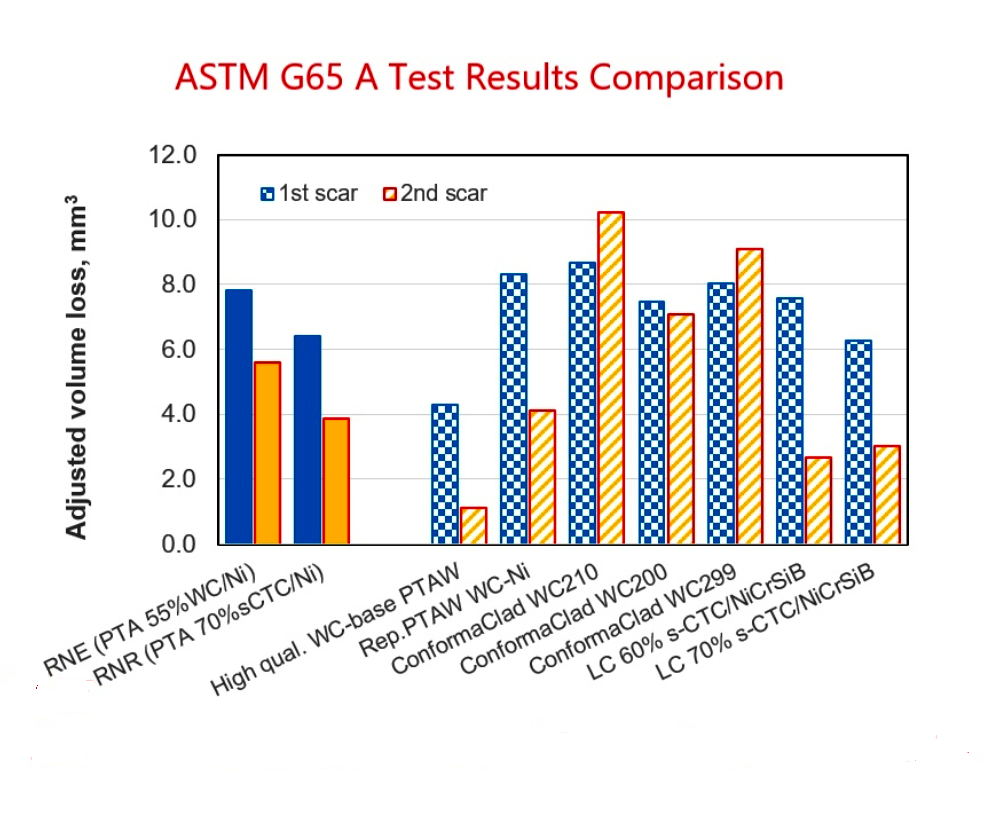

Test Reports On PTAW Products:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Answer: It depends on the hardfacing alloy. Many chromium carbide alloys check-crack when cooled to moderate temperatures; this is normal. Other alloys, such as the austenitic and martensitic, do not crack when applied properly. Check cracking can be seen as cracking perpendicular to the bead length. This occurs by the high stress that is experienced when the weld metal cools. The cracking stops at the parent metal underneath, as long as the parent metal is not brittle. If the parent metal is hard or brittle, you should choose a buffer layer of a softer, and tougher, weld metal.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Related Keywords