2021 Good Smooth Hardfacing Wear Plate

-

$1.00100-99 Kilogram

-

$9.90≥100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 50,000㎡ wear plate per year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

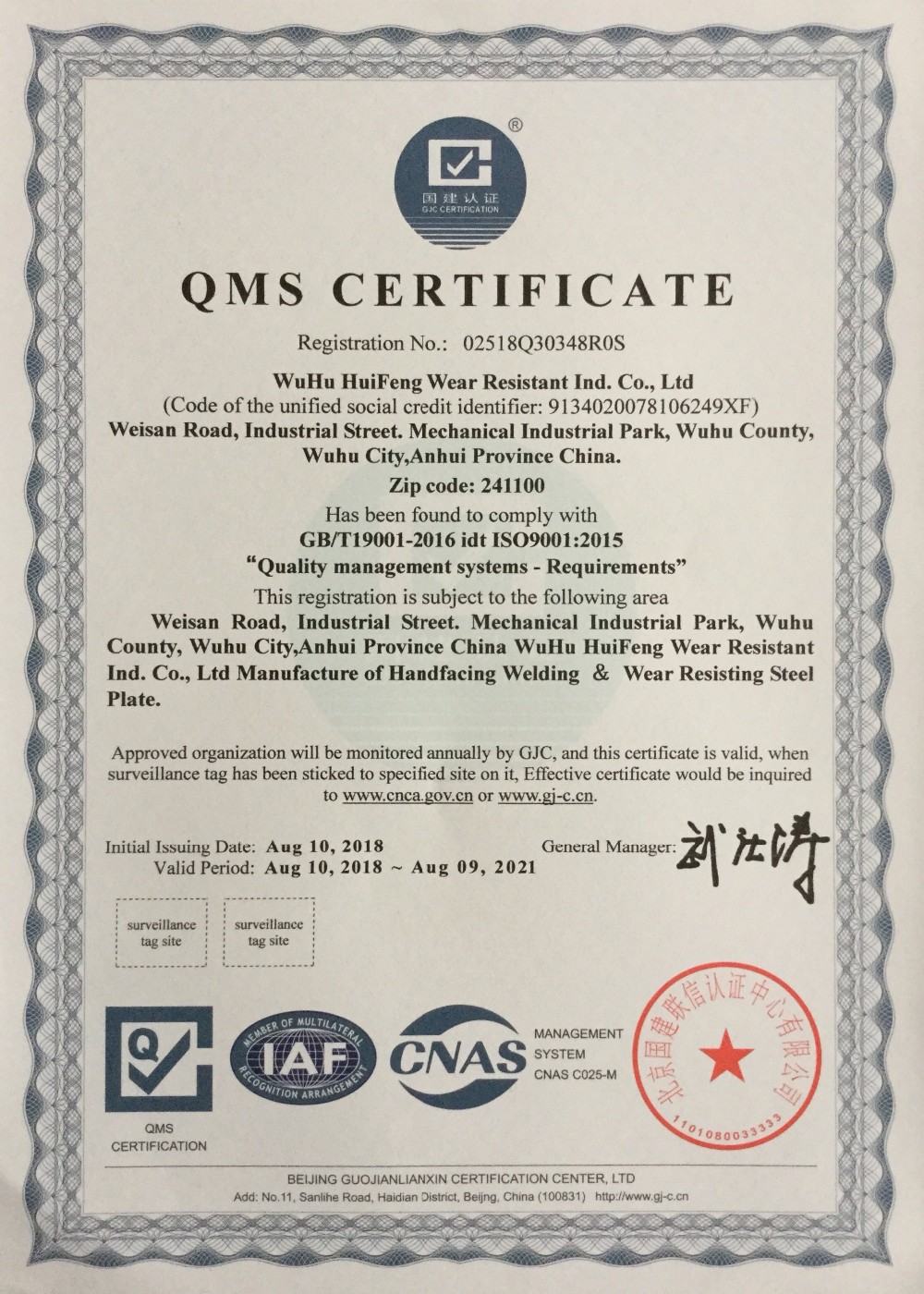

| Certificate: | ISO9001: 2015 |

| HS Code: | 72109000000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Qingdao,Shenzhen |

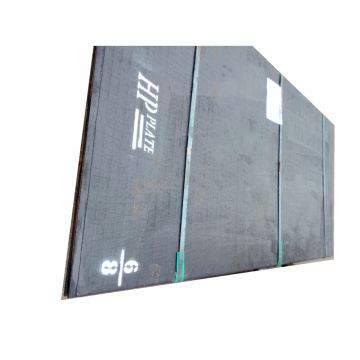

2021 Good Smooth Hardfacing Wear Plate

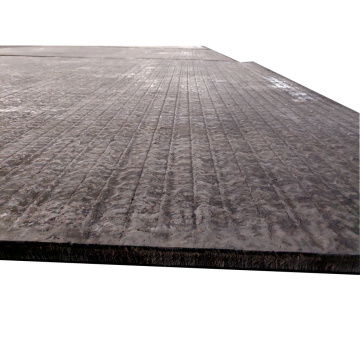

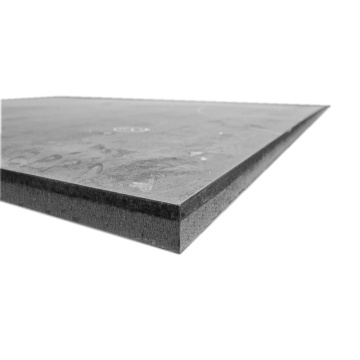

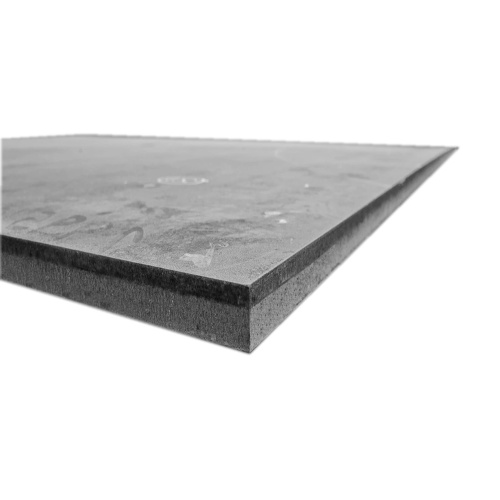

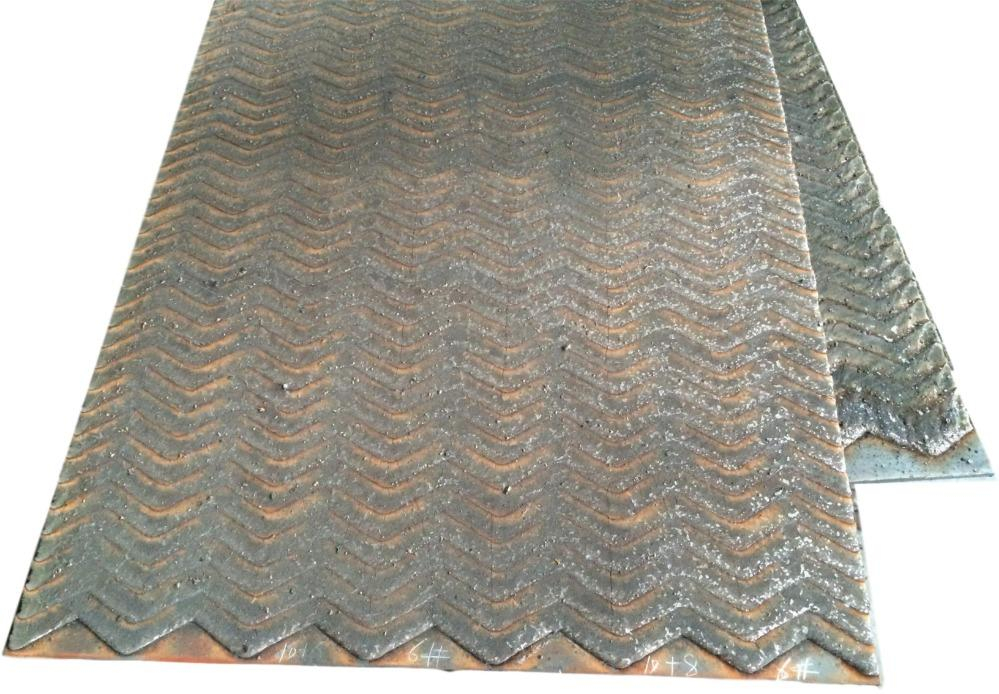

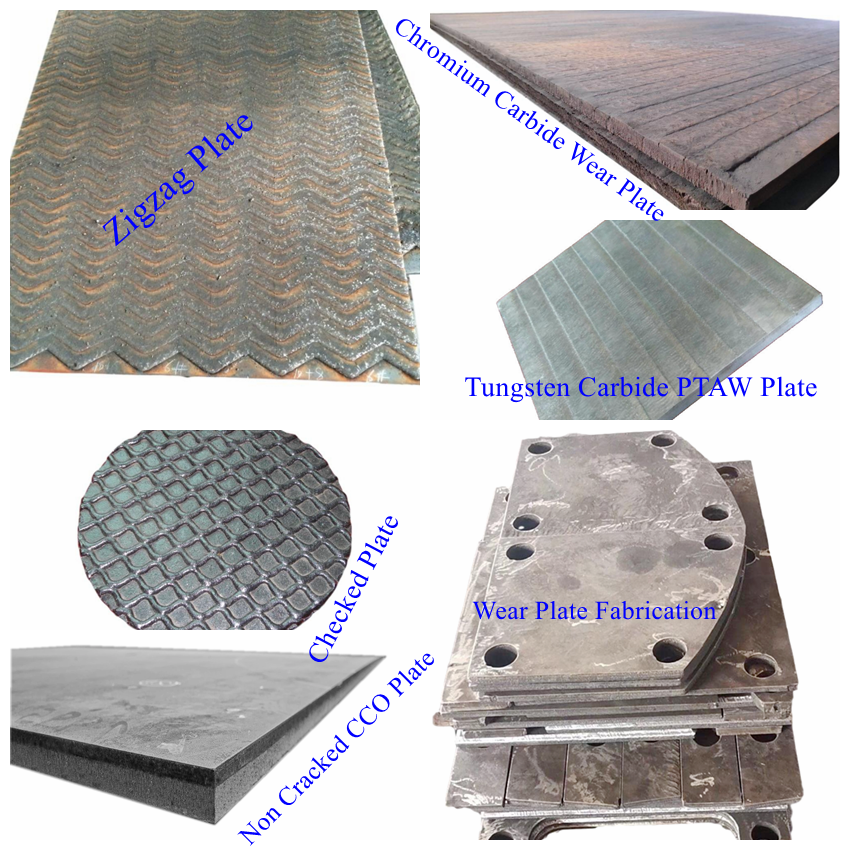

There are a wide variety of Composite Wear Plate available and each performs well in specific working condition. HP Non Cracked Overlay Plate is Smooth Hardfacing Wear Plate, the non-stick surface minimizes or eliminates material adhering to the surface of equipment.

The low coefficient of friction reduces sticking or carryback in a variety of application such as chutes, hoppers, and mobile equipment and truck box liners, Cement Vertial Mill Wear Plate.

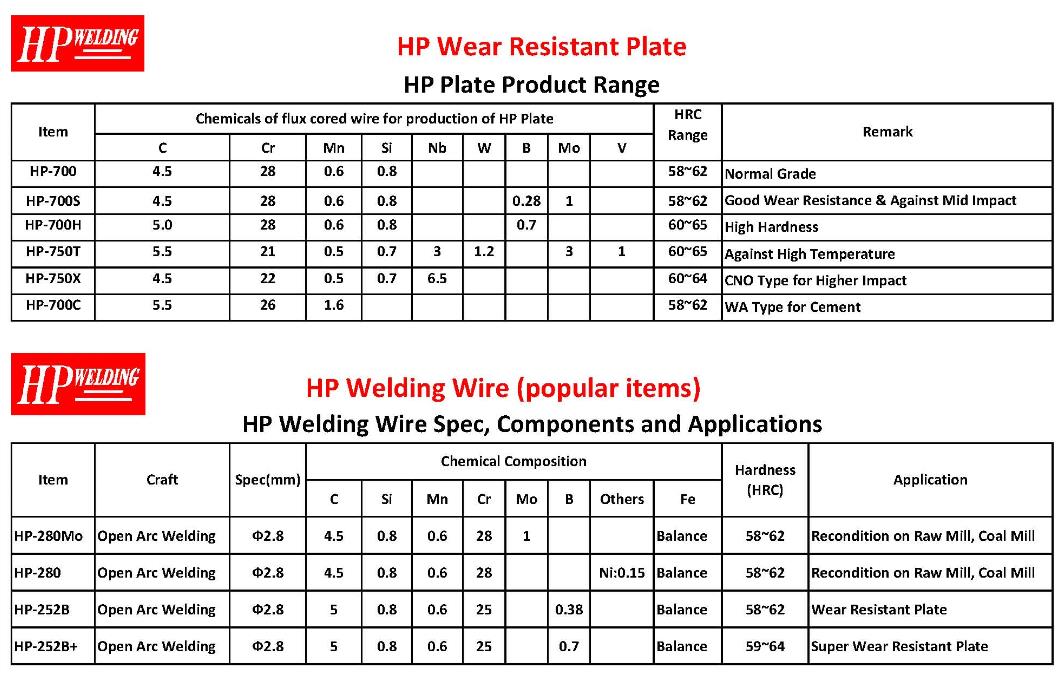

Standard Specifications of HP Wear Plate :

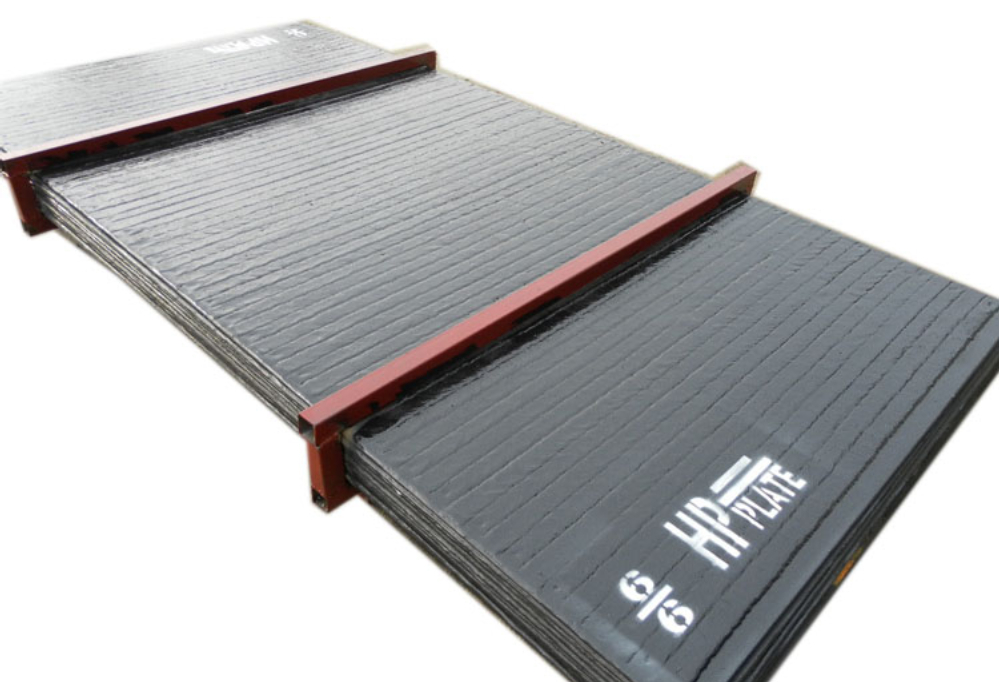

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Related Keywords