Hot sale Innershield Welding Wire

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10 tons daily |

| Supply Ability: | 10 tons per day |

| Payment Type: | L/C,T/T,D/P,Paypal,D/A |

| Incoterm: | FOB,CIF,FCA,CFR,EXW,CPT,FAS,CIP,DEQ,DDP,DDU |

| Certificate: | ISO9001: 2015 |

| HS Code: | 8311200000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Qingdao,Shenzhen |

Hot sale Innershield Welding Wire

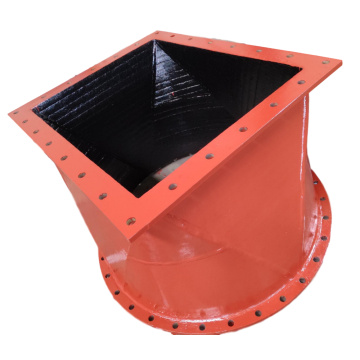

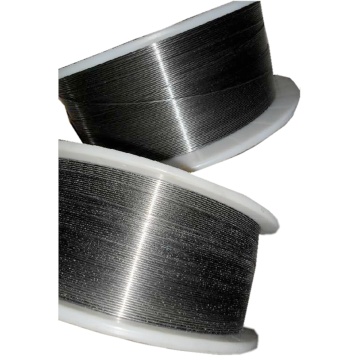

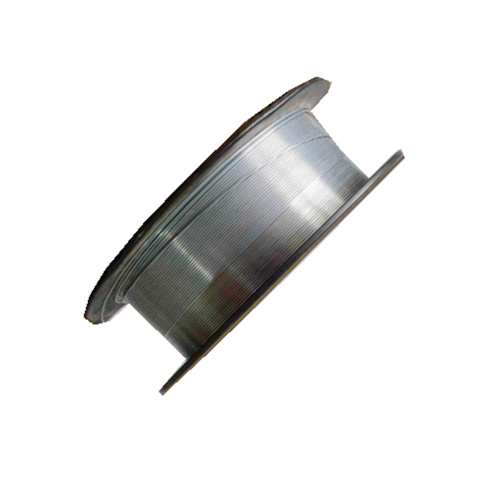

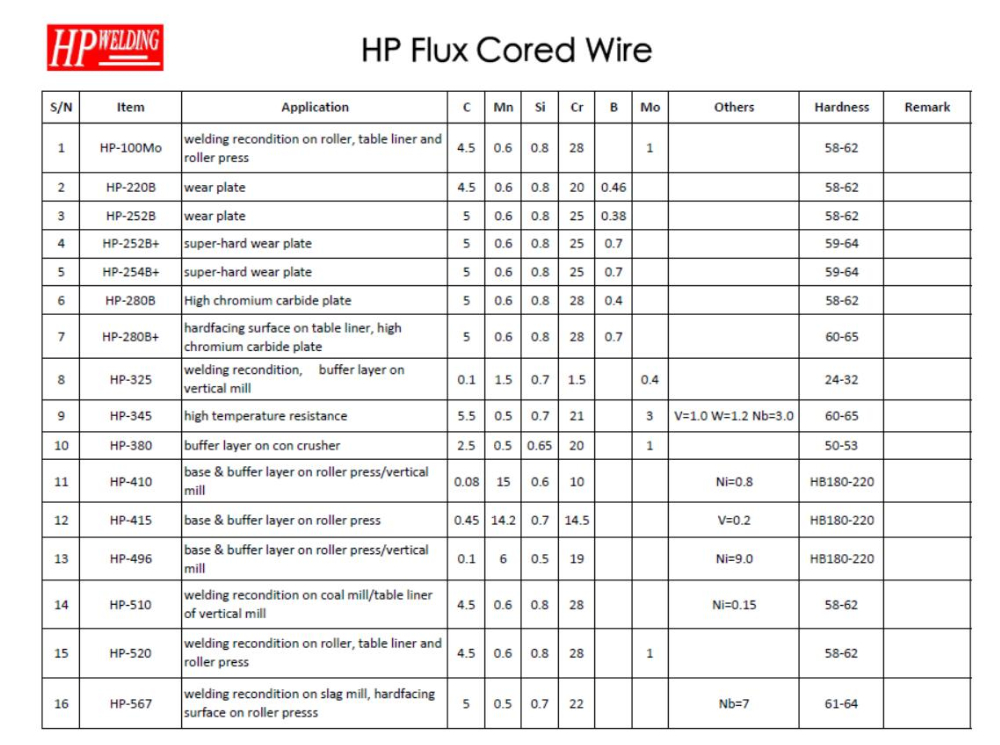

HP Welding manufactures Flux Cored Welding Wire and metal cored hardfacing consumables. We offer welding wires for low, medium and high alloy hardfacing, which provide good protection as wear solution material including abrasion, impact. Our range of hardfacing welding wires dedicated to increasing abrasion resistance including Molybdenum Carbide Welding Wire, Stainless Steel Flux Core Welding Wire, Stoody, Premium Hardfacing Welding Wire. Flux cored wires and metal cored wires suitable for increasing wear resistance of parts such as screw conveyors, fans, equipment used in agriculture & mining, grinding mills, vertical mills, screws, blades, ventilators and more.

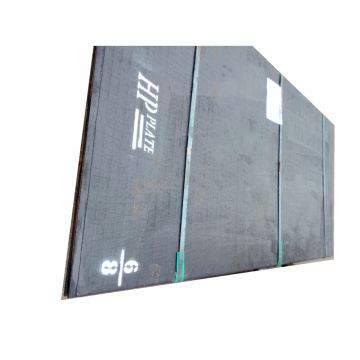

Standard Specifications of HP Wear Plate by HP flux cored wire:

Packing & Delivery Of Flux Cored Wires

Packing & Delivery Of Flux Cored Wires

Packing Way: Opt.1_5kg By Reel, Opt.2_ 250kg By Drum

Delivery Time: 20 days after order confirmation

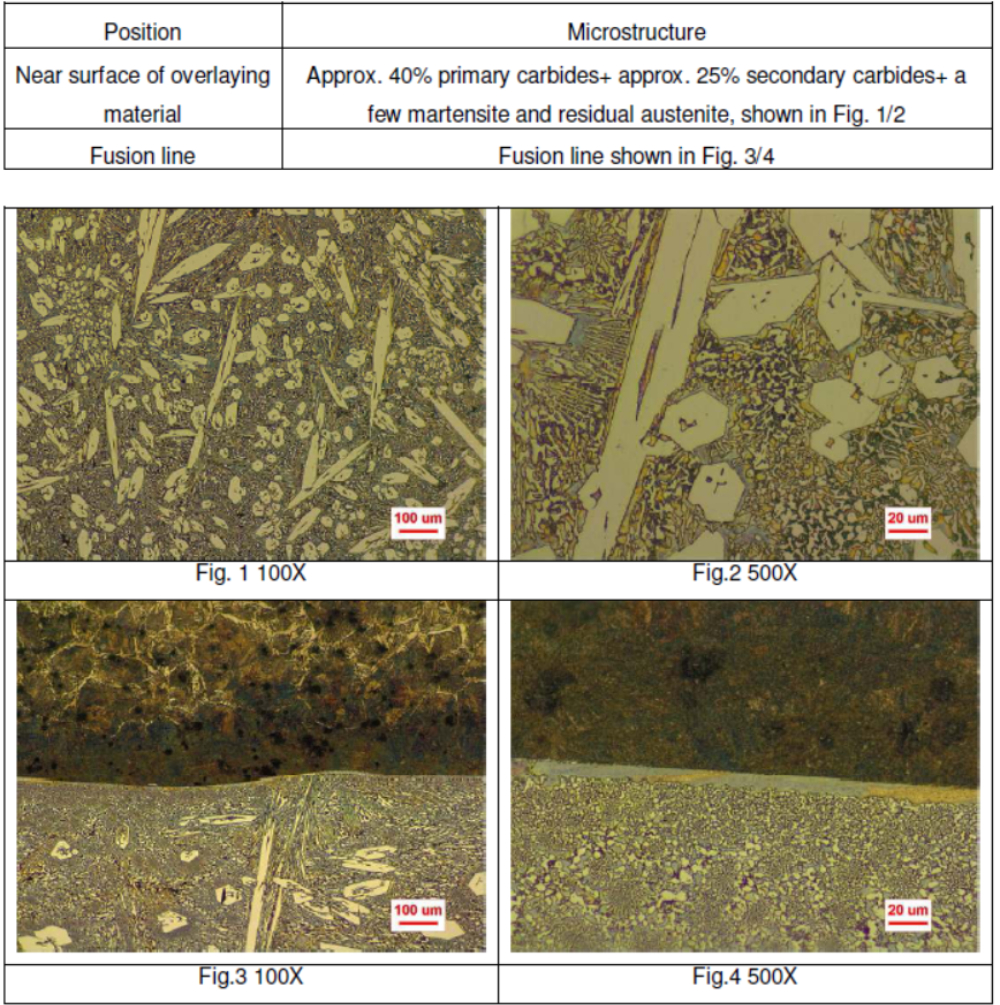

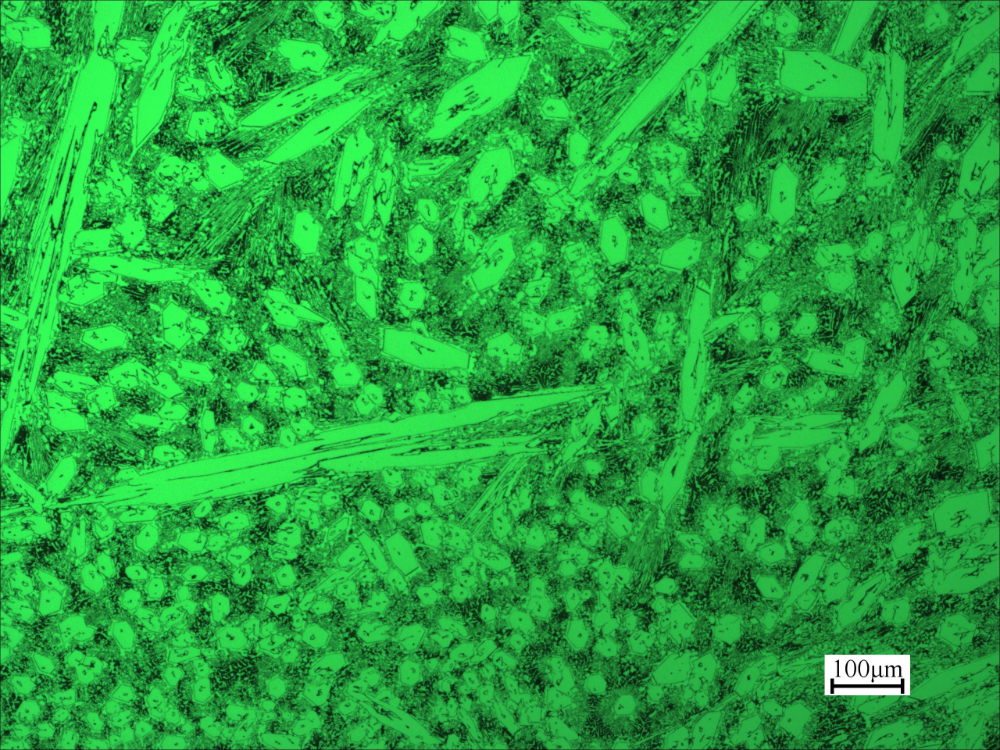

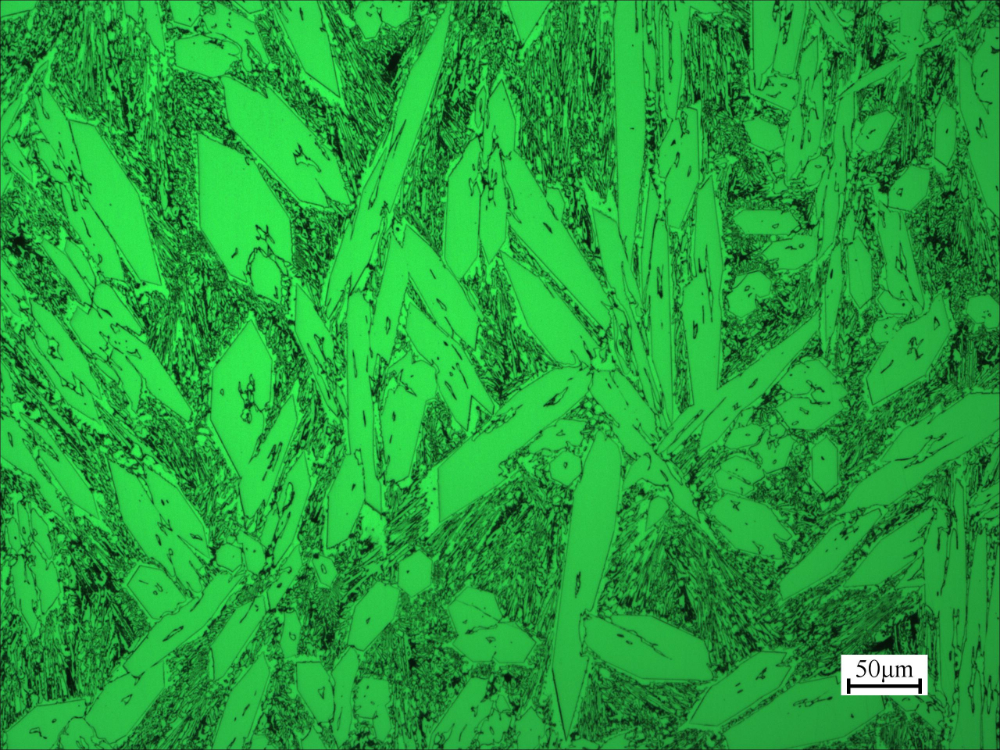

Micro Structure On Welding Deposite

Company Information

HP Wear Resistanat Group was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Group has become the most experienced expert specializing in production and sales of wear resistant products.

Test Facilities On Welding Wires

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Related Keywords