Good quality Shell Lining Plate

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- S, h, a

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 500 tons per year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

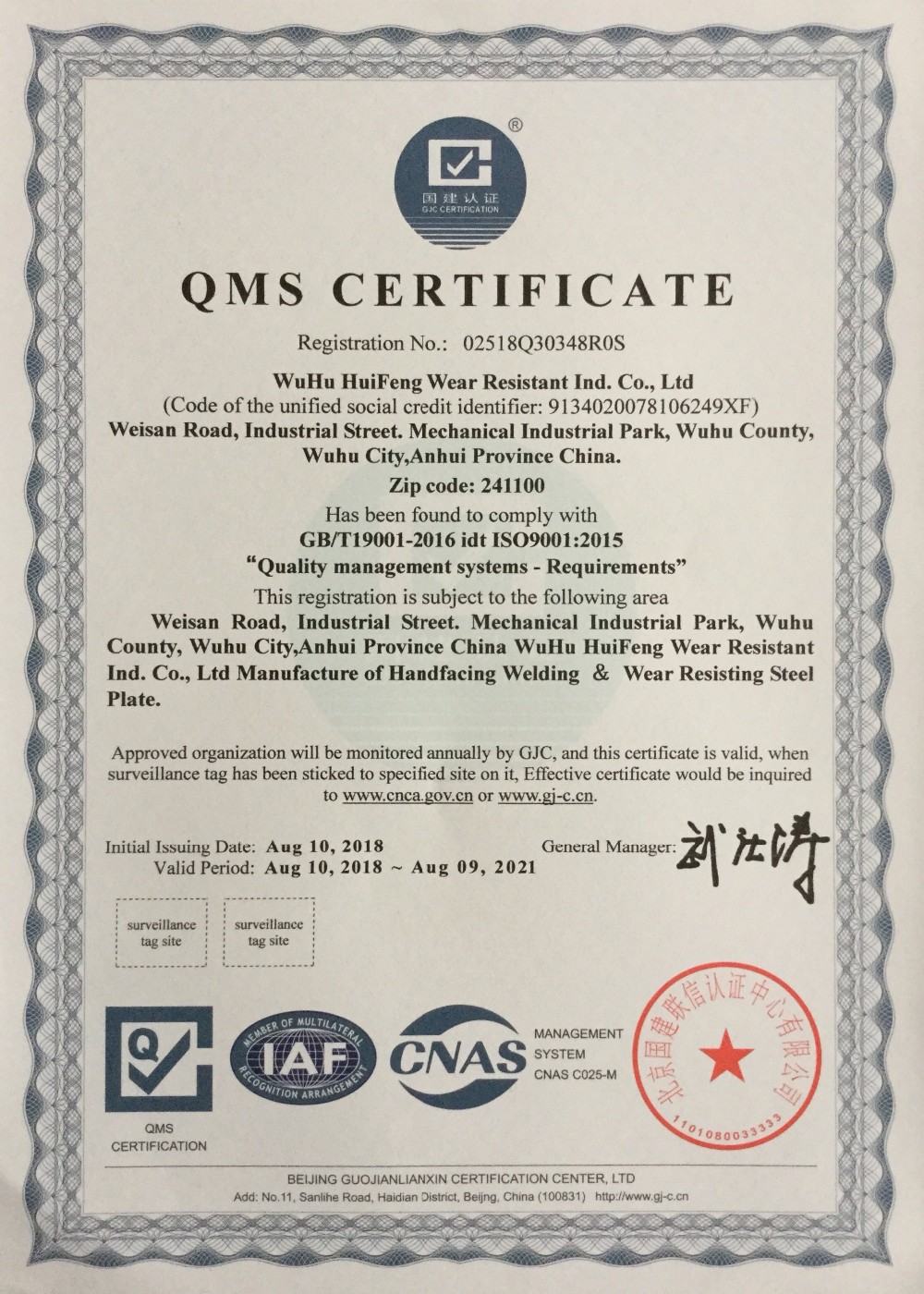

| Certificate: | ISO9001: 2015 |

| HS Code: | 84749000 |

| Transportation: | Ocean,Land,Air |

| Port: | S,h,a |

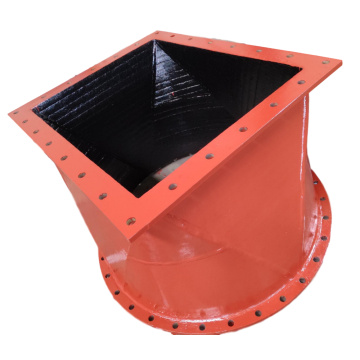

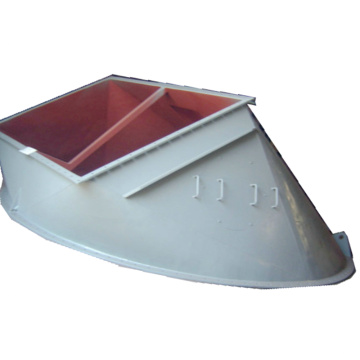

We are specialized in designing and manufacturing wear resistant parts, like Ceramic Liners, Buckets, Hopper Liners, etc…Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

- with excellent anti-abrasion and high elasticity, main to reduce pressure from outside parts.

- good combination performances, wear resistance, chemical resistance,

- perfect mechanical strength and long elongations.

Chutes, Dragline Bucket Liner, Crusher Wall Liner, Ceramic Wear Liners, Liner Ceramic all are available at your need.

The feature on HP Wear Parts

- Longer wear life

- Reduce downtime

- Improve liquidity

- Easy to install

- Reduce welding

- Flexibility

- Adaptability

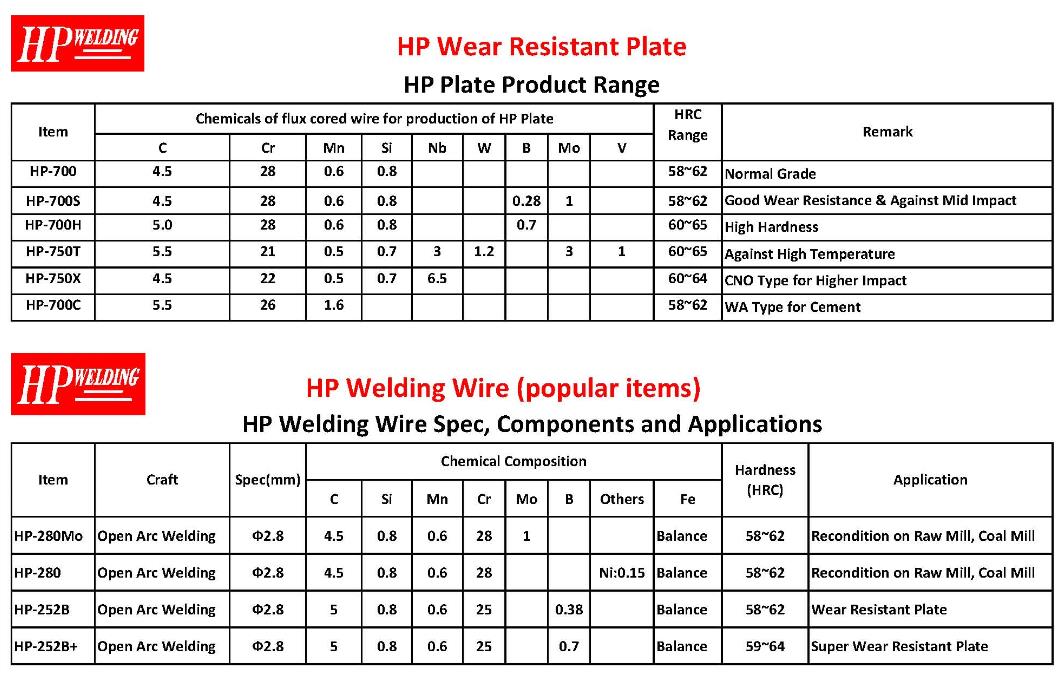

Standard Specifications of HP Wear Plate :

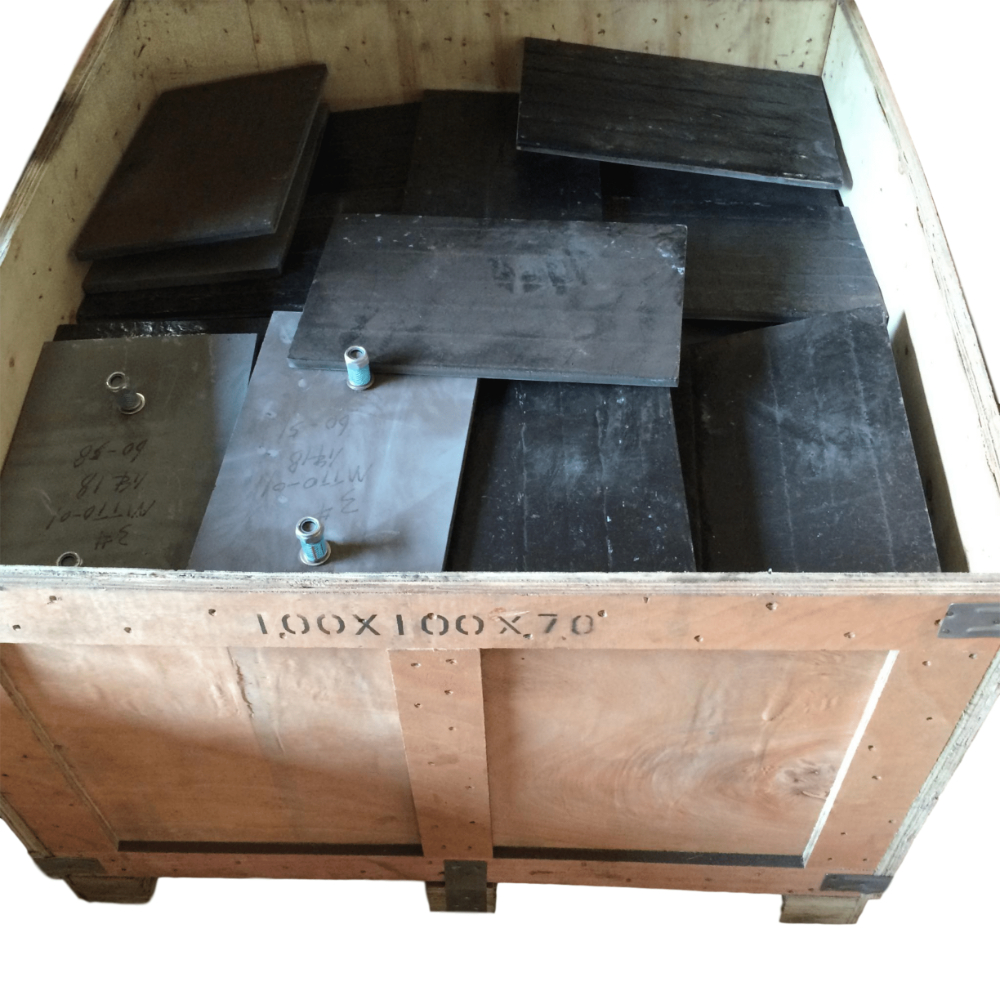

Packing & Delivery of Wear Plate

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 30 days after order confirmation

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

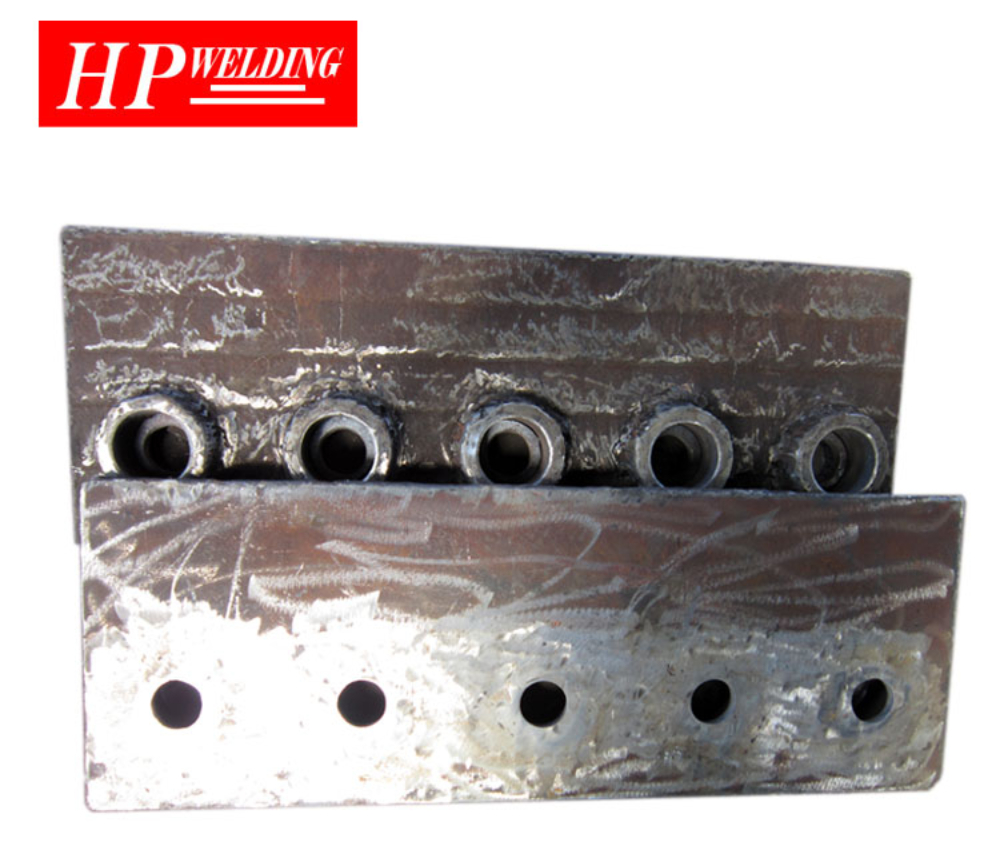

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert providing one-stop wear solution & products.

HP Wear Products Range:

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Related Keywords