Wear Plates/Abrasion Wear Resistant Steel Plates

-

$1.00100-99 Kilogram

-

$9.90≥100 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- S, h, a

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 tons per year |

| Supply Ability: | 50,000㎡ wear plate per year |

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

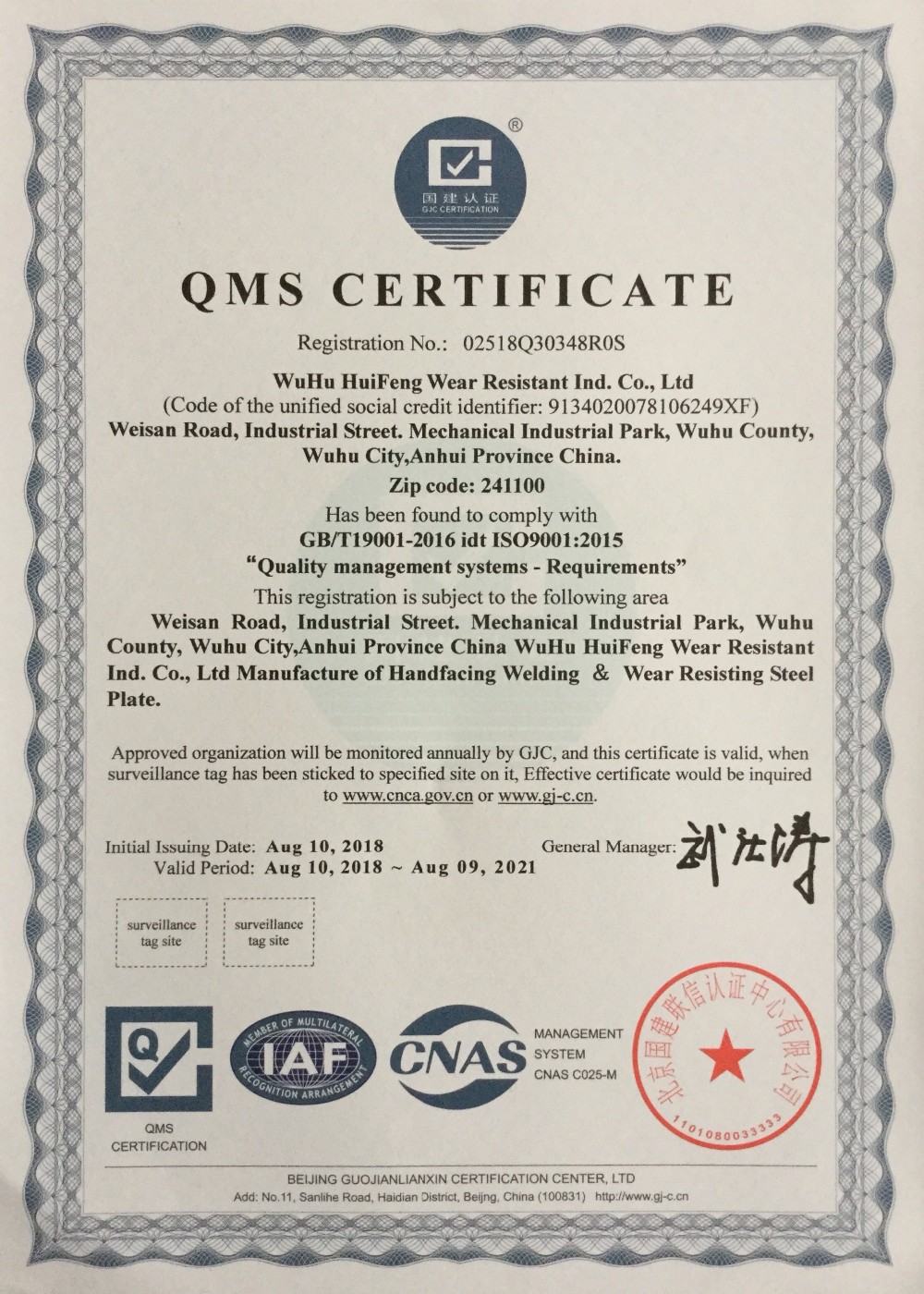

| Certificate: | ISO9001: 2015 |

| HS Code: | 72109000000 |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | S,h,a |

Wear Plates/Abrasion Wear Resistant Steel Plates

HP Group offers the High End Abrasion Resistant Steel Plates to market.

Steel surfaces exposed to high temperatures for long periods of time can steadily deteriorate. Heat affects the metal's microstructure and generally reduces its durability. The wear resistance of most alloys diminishes when exposed to high heat in service due to softening of inadvertent tempering.

A major cause of metal failure from high temperature service is thermal fatigue or fire cracking. This results from repetitive intense heating followed by quick cooling. The repeated expansion and contraction caused by this thermal cycling eventually exceeds the ability of the metal to recover and causes deep cracking.

A martensitic steel containing 5-12 % chromium is used extensively to combat thermal fatigue. Many chromium-carbide Abrasion Resistant Steel Plates retain their wear resistance up to temperatures of 1200 °F (630 °C). Service conditions over that temperature generally require a non-ferrous alloy like AR Steel Plate. Typical components subject to high temperature wear include continuous caster rolls, steel mill work rolls, hot forging dies, CDP Steel Liner Plate, Wear Plate for Chute Liners.

Quick View On Product

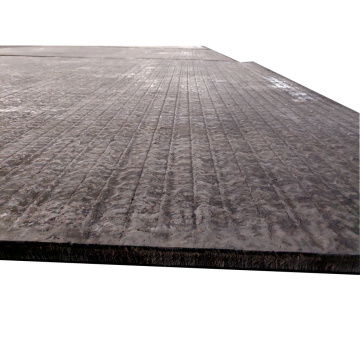

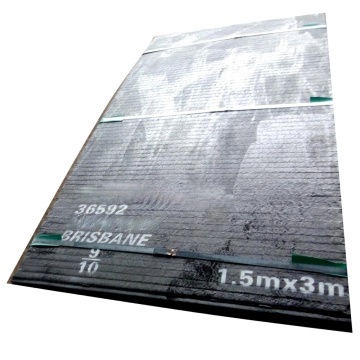

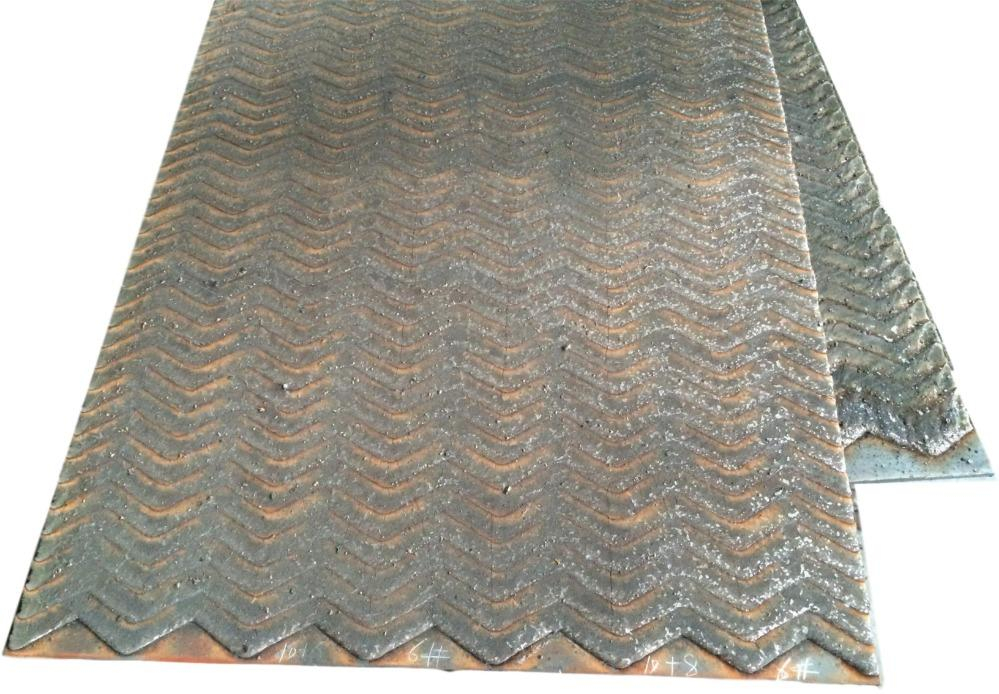

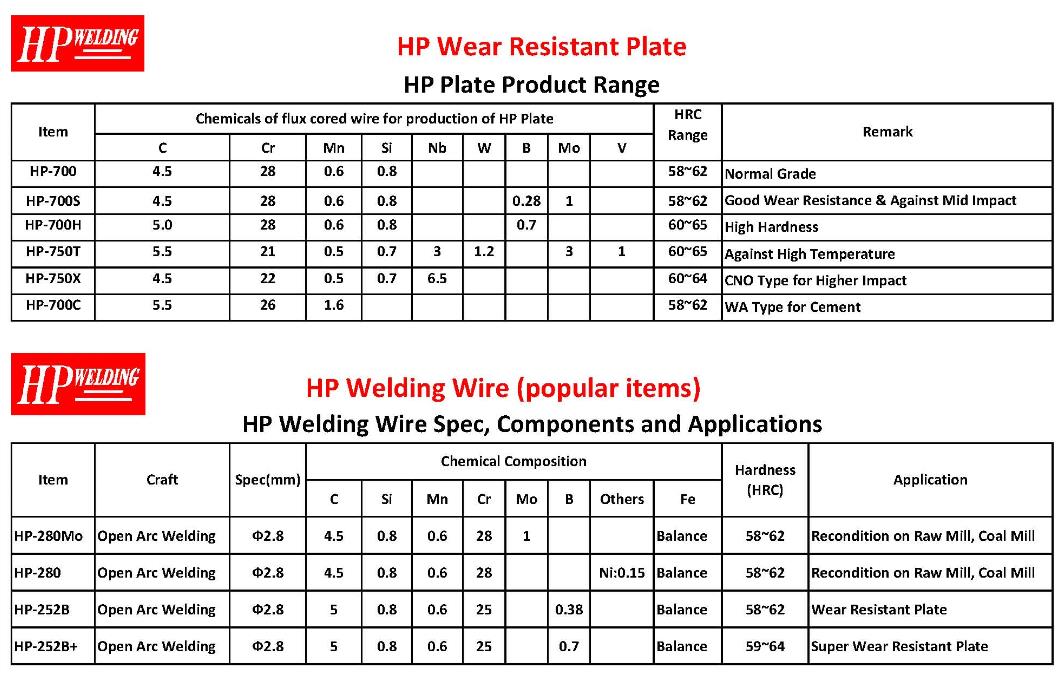

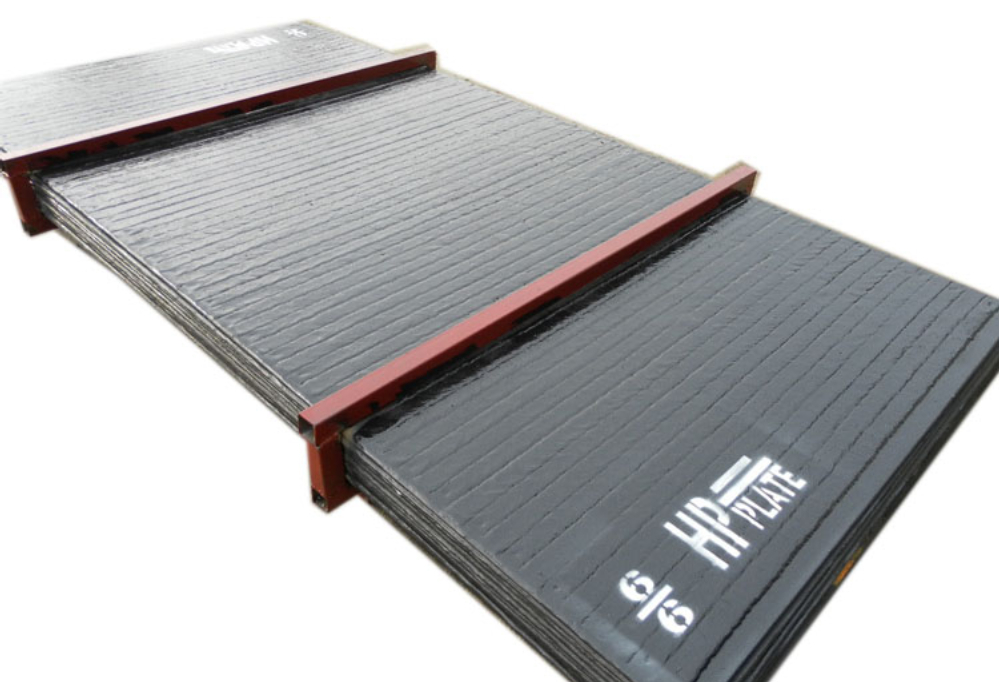

1. Product Name: HP Chromium Carbide Overlay Wear Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

3. Grade: HP700, HP700S, HP750X, HP750P

Standard Specifications of HP Wear Plate :

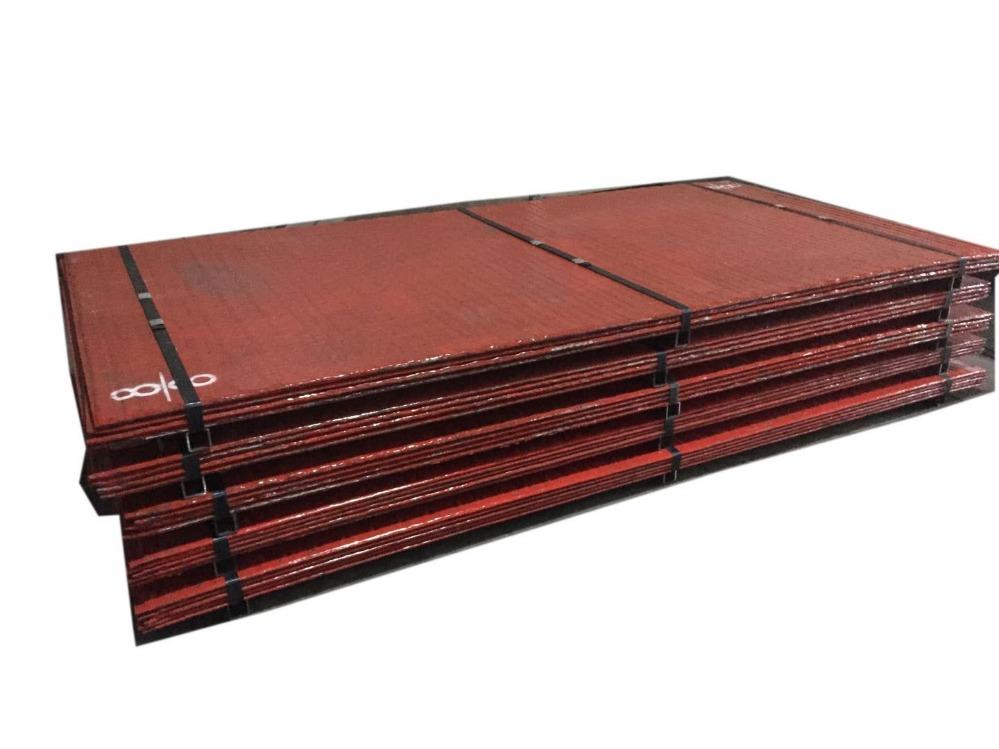

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Related Keywords