Full Automatic Barrel Production Line

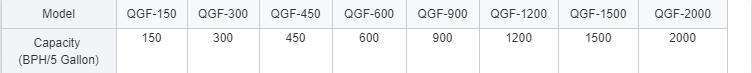

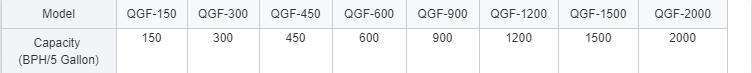

The filling line special for 3-5 gallons barreled drinking water,with type of QGF-150,QGF-300,QGF-450,QGF-600,QGF-600,QGF-900,QGF-1200,QGF-1500,QGF-2000.It integrates bottle washing,filling and capping into one unit.In order to chineve the purpose of washing and sterilizing.The washing machine uses multi-washing liquid spray.This thimerosal can be used circularly.The capping machine can automatic.This line equips with water spraying device in order to ensure those caps sterile and clean.It also can automatic carry out barrel.Washing,sterilizing,filling capping,counting and products discharging.With complete fuction,modern design and high degree of automation.It is new kind of barreled water auto-producing line,which integrates mechanism,electricity and pneumatic technologies together.

Washing-filling-capping machine is the core equipment especially for 5 gallon filling line, which is the ideal equipment for producing mineral water, pure water and still water. It is made of quality stainless steel, anti-corrosion and easy to clean.

Barreled Pure Water Filling Machine Bottling Production Line

The machine is used for 3 gallon & 5 gallon water filling, which is composed of washer, filling and capper.

1. 304 stainless steel insert type filling nozzle, two time high precision filling, filling volume adjustable.

2. Water pump: 304 stainless steel pump. three washing pumps and one filling pumps.

3. Mitsubishi PLC controlling system, all full-automatic working, Schneider & Omron brand other electric parts

4. With AIRTAC brand air cylinder, F.R.L. Combination and Electromagnetism valve for air cylinder.

5. Machine frame and body: all 304 Stainless Steel, combine with clear fiber glass windows

Bottled Water Purifying Machine

Water Bottling Filtering Machine

Details

Cap Decapper

This model automatic decapper is special equipment for 5-gallon retrieving barrel. It does not damage caps.

This machine adopts computer control and its capacity can be adjusted. Cap pulling organism from AIRTAC adopt

pneumatic adjustment, which solves the problems of tolerance of barrel height and tolerance of barrel's mouth, and

increases cap pulling success greatly. 304 stainless machine frame and machine body.

Bottle Filling Machine

Outer Brusher

Function: clean the external of 5 gallon bottles with brush and water

1. Rotary style to wash the bottle body.

2. Material of machine frame and body: all 304 Stainless Steel.

3. All 304 stainless steel pipeline , valve and connector, fine polish, no death corner

4. Linear washing style with ø350brush 1pc ø200 brush 3pcs 300*3 brush 20pcs

5. Water pump: with 304 stainless steel pump

6. Washing tank: size 500*300*600*1.2, 304 stainless steel

7. No bottles, no washing

Liquid Filling Machine,Bottle Filling Machine Manufacturer

Washing-filling-capping 3-in-1 Monoblock

1. 3-rows 12-washing stops. Everything stop is about 23 seconds

2. 304 stainless steel insert type filling nozzle, two time high precision filling, filling volume adjustable.

3. Water pump: 304 stainless steel pump. three washing pumps and one filling pumps.

4. Mitsubishi PLC controlling system, all full-automatic working, Schneider & Omron brand other electric parts

5. With AIRTAC brand air cylinder, F.R.L. Combination and Electromagnetism valve for air cylinder.

6. Machine frame and body: all 304 Stainless Steel, combine with clear fiber glass windows

Liquid Filling Machine

Conveyor

Function: convey the empty and the filled bottles

1. The total length is subject to layout

2. Motor drive

3. SUS304 stainless steel frame and chain plate