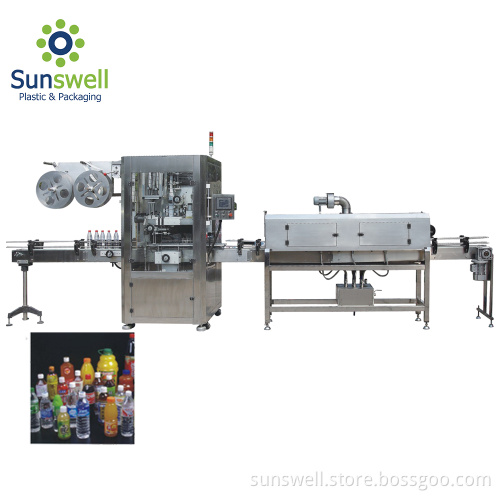

Automated Bottling Labeling Machine

-

$4000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000-9000 bottles per hour |

| Supply Ability: | 20 sets per month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo |

Description

This bottle labelling machine is equipped with SS304 cover and aluminumalloy structure. It is suitable for the round bottle, square bottle, oval bottle, flat bottle, curve bottle, bottle mouth and bottle body. Blade replacement is easy and cost is low. Servo motor controls cutting operation to last the blade service time and make label more accurate. It owns automatic computer control, automatic detection, automatic positioning, fast label replacement, accurate label cutting, colour HMI with English and other characteristic. This labelling machine is easy to operate and no worker needed. It equipped with alarm device.

Bottling Labeling Machine

Wet Glue Labeling Machine From China Manufacturer

Application

Suitable for various kinds of bottle type of fruit juice, tea beverage, dairy products, pure water, condiment, beer, sports drinks such as food and beverage.

Bottle Type

round bottle, square bottle, flat bottle, curve bottle, cup and so on.

Features

1).The standard position precision is high, and shrinkage can highlight the perfect shape of bottle.

2).High and stable mechanical structure of the whole machine adopts stainless steel protection box cover and aluminum alloy rigid frame, solid doesn't rust.

3).High quality positioning accuracy: all mechanical transmission design, using force set timescale, and various membrane materials 0.03-0.13mm film thickness, membrane material applies 5-10 range inner diameter can be adjusted.

4).Low maintenance cost: the spare parts of the machine is easy to change, low cost burden.

5).Reliable after-sale service: this machine various spare parts warehouse all have spare, can offer, and experienced engineers provides technical support.

6).Exclusive design :reciprocating cutting knives, adopt high technic, rigid body movements smooth, the tool life extend one times.

7).The structure of the machine is simple and easy, can ensure low failure rate, maintenance and simple.

8).Simple type center word column positioning, specifications, the operator is convenient to use easy replacement of manipulating plain, easiness, completely avoid the user's problems.

Square Bottle Labeling Machine

Bottling Labeling Machine

Labeling Machine Data

|

Type

|

TB-150A

|

|

Main engine size (length*width*height)

|

1700L*800W*2000H(mm)

|

|

Machine Weight

|

1800Kg

|

|

Main engine production speed

|

Max. 12000 bottle per hour

|

|

Main engine power supply

|

3,380v/220v

|

|

Main engine power

|

5KW

|

|

Label length

|

25mm-180mm

|

|

Label thickness

|

0.035mm-0.13mm

|

|

Label material

|

PVC.PET.OPS

|

|

Bottle/can height

|

15mm-320mm

|

|

Bottle/can diameter

|

28mm- 125 (special design for extra-big bottle)

|

|

Bottle/can shape

|

round, square, elliptic, rectangular

|

Shrink Tunnel

|

Input Power Supply of Blower

|

AC220/380V 50Hz 1.1KW

|

|

Transporting Speed

|

0-35M/min

|

|

Working Pressure

|

≤0.1Mpa

|

|

Steam Consumption

|

10-20Kg/H

|

|

Weight

|

230kg

|

|

Overall size

|

1800x400x400mm(LxWxH)

|

Steam generator

|

Input Power Supply of Blower

|

AC220V/380 18KW

|

|

Steam Pressure

|

0.25-0.4Mpa

|

|

Vapor Generation Value

|

48Kg/h

|

|

Weight

|

96kg

|

|

Overall size

|

600x550x1200mm(LxWxH)

|

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Related Keywords