Automatic Aluminum Foil Sealed Beverage Filling Machine

-

$20000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | jiangsu,china |

|---|---|

| Productivity: | According to customer requirem |

| Supply Ability: | 100 sets per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

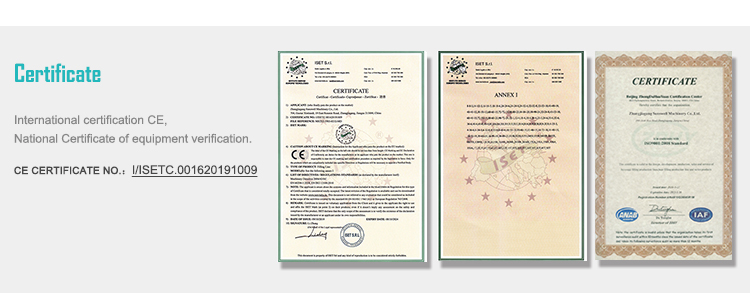

| Certificate: | CE ISO |

| Transportation: | Ocean,Land |

| Port: | Shanghai |

Product Description

The monoblock washing,filling and capping machine offer the industry's most proven washer,filler and capper technology in one simple, integrated system. In addition they deliver the high performance today's high speed packaging lines demand. By precisely matching the pitch between washer, filler and capper, monoblock models enhance the transfer process, reducing atmospheric exposure of filled product, eliminating deadplates, and significantly reducing feedscrew spills.

This is Beverage Filling Machine

|

Product name

|

Drinking/Mineral/Pure Water Rinsing-Filling-Capping Machine

|

|

Bottle Type

|

Plastic Bottle

|

|

Capacity

|

5000BPH-20000BPH

|

|

Filling Volume

|

180ml-2000ml

|

|

Filling Principle

|

Gravity Filling

|

|

Filling Accuracy

|

±5%

|

|

Material

|

SUS 304/316L

|

|

Structure

|

Washing Filling Capping

|

|

Filling Valve Head

|

Multi-head

|

|

Dosing Device

|

Surface Type

|

Features

1) The machine has compact structure, complete control system, easy operation and high degree of automation

2) To change bottle shape, the operator only needs to replace the star-wheel, inlet bottle screw and arc guide plate

3) The parts contacting media are made from 304and have no process blind angles to enable easy cleaning

4) High speed filling valve, guarantees liquid has precise level and no waste is incurred

5) The capping head applies a constant magnetic torque device to secure capping quality and prevent damage to the bottle cap

6) The control system has the function of control producing speed, cap shortage detection, bottle block auto stop and production counting

7) The machine applies a highly effective cap arranging system that has complete self control and protective device

8) The machine is equipped with a complete overload protection device that can secure equipment and the operator effectively

9) Main electric components and pneumatic components apply world famous brand products

10) The machine's operation is controlled by an advanced touch-scree

Liquid Filling Machine

Why Choose Us

About Sunswell:

Automatic Bottled Water Production Line

Any more questions, please feel free to contact us!

FAQ:

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units tosave international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Related Keywords