PLC programming control, servo motor drives a stable double-screw transmission mechanism to ensure accurancy and stability when the piston cylinder is pushed. It can achieve fast and slow filling;

Automatic Daily Chemical Filling Bottling Machine

- Payment Type:

- L/C

- Incoterm:

- FOB

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 60 Days

- Transportation:

- Ocean

- Port:

- Shanghai Port

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 4000BPH 500ml |

| Supply Ability: | 20 sets per month |

| Payment Type: | L/C |

| Incoterm: | FOB |

| Certificate: | CE ISO |

| HS Code: | 8422302100 |

| Transportation: | Ocean |

| Port: | Shanghai Port |

Product Description

Product Description

This machine adopts PLC microcomputer programmable control, which integrates light, machine, electricity, sensing and pneumatic execution. The stroke of the injection cylinder is driven by a servo motor, and the stroke is positioned accurately. The machine is highly automated and easy to adjust. When changing the specifications or correcting the measurement, only the adjustment on the display can meet the precise measurement required. It can be used for filling various viscous materials such as food, dailychemical, vegetable oil, jam, honey, syrup and so on.

Technical Parameter

|

Production Capacity

|

4000BPH (500ml)

|

|

Applicable Bottle

|

Length 80-220mm, Height 60-300mm

|

|

Accuracy

|

±0.2%

|

|

Air Pressure

|

0.6-0.8Mpa

|

|

Voltage

|

220V, 380v, customized

|

|

Power

|

1.5kw

|

|

Dimension

|

2400×1300×2300

|

|

Weight

|

1300kg

|

Features

PLC programming control, servo motor drives a stable double-screw transmission mechanism to ensure accurancy and stability when the piston cylinder is pushed. It can achieve fast and slow filling;

Adopt 316 integral casting filling head, with high integrity and long service life;

3.

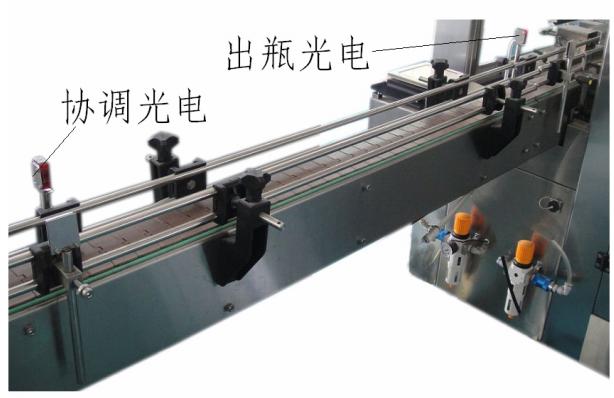

The conveyor belts are equipped with coordinated photoelectric to intelligentlydetect the bottle-in and bottle-out. In case of bad conditions, they can automatically stop, reduce manual intervention and intelligent;

4.

Piston seals with PTFE carburizing technology, which improve wear resistance, longer service life, and reduce maintenance costs;

5.

Hoppers, valves, piston cylinders, filling heads all adopt live connection devices, which is convenient for replacement of sealing rings and disassembly for cleaning and disinfection;

6.

The components that need to be adjusted are all connected by quick connection. It is very convenient to replace the specification and adjust them;

7.

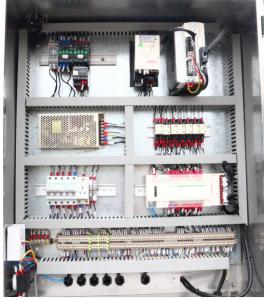

The whole electrical control system adopts well-known electrical brands (Schneider, Siemens), integrated electrical control system, more stable and reliable, safe, green, low energy consumption, environment protection (the electrical configuration can be changed according to customer requirement);

8.

The whole machine can be used for bottles of different specifications, easy to adjust, and can be complete in a short time.

Adopt imported photoelectric detection and induction, accurate positioning, filling with bottles, no filling without bottles, automatic counting function.

|

NO.

|

Item

|

Brand

|

|

1

|

Touch Screen

|

Weinview, Taiwan

|

|

2

|

PLC

|

Mitsubishi, Japan

|

|

3

|

Solenoid Valve

|

AirTAC, Taiwan

|

|

4

|

Frequency Converter

|

Schneider, France

|

|

5

|

Breaker

|

Schneider, France

|

|

6

|

Servo Motor

|

Panasonic, Japan

|

|

7

|

Switch

|

Schneider, France

|

Related Keywords

Related Keywords

You May Also Like

You May Also Like