High Speed Servo Blow Molder

-

$4000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 4000BPH |

| Supply Ability: | 50 sets per year |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB |

| Certificate: | CE |

| HS Code: | 842230 |

| Transportation: | Ocean |

| Port: | Shanghai |

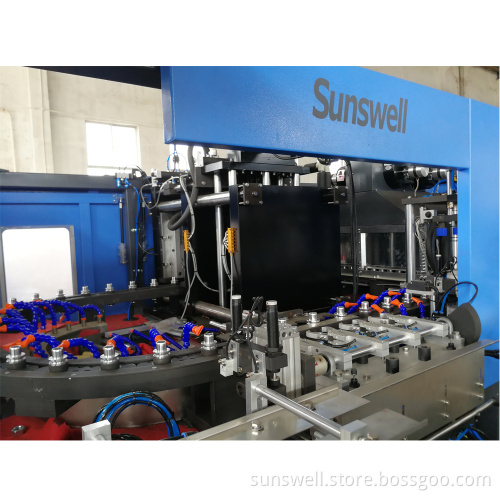

Sunswell developed the special servo blow molder for PET can and bottles.

Sunswell machinery has rich experience to design various reheat stretch blow moulding equipments. After years of R&D, now we introduce the latest economical stretch blow moulding machine to the market. The SSW-A is an economic two stage automatic stretch blow moulding machine, which is mainly designed for the PET and PP stretch blow bottles. The SSW-A consumes less power due to optimized machine layouts and patented perform heating system, so the end of user can achieve maximum profit in today's competitive bottle moulding market.

Pet Stretch Molding Machine Manufacturer

Extrusion Blow Moulding Machine

Machine futures:

Stable performance with advanced PLC.

Conveying preforms automatically with conveyor.

Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

Blow Molder,Pet Stretch Molding Machine

Bottle Blowing Machine

Strong clamping force with high pressure and double crank links to lock the mold.

Two ways of operating: automatic and manual.

Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

Contamination is avoided for the bottle body.

Ideal effect of the chilling with the chilling system.

Easy installation and starting.

Low rejection rate: less than 0.3percent.

Technical parameter

|

Container |

Max. Container Volume |

ltr |

2 |

|

Max. Neck Diameter |

mm |

50 |

|

|

Max. Container Diameter |

mm |

110 |

|

|

Max. Container Height |

mm |

320 |

|

|

Molding |

Clamping Force |

kg |

26000 |

|

Clamping Stroke |

mm |

125 |

|

|

Stretching Stroke |

mm |

450 |

|

|

Bottom Stroke |

mm |

40/70 |

|

|

Cavity Spacing |

mm |

120 |

|

|

Number of Cavity |

cavities |

6 |

|

|

Carriage Unit |

pcs |

162 |

|

|

|

Theoretical Output |

bph |

5000-6000 |

|

Electrical System |

Total Power |

kw |

78 |

|

Heating Power |

kw |

48×1.5KW=72 |

|

|

Number of Lamp Layers |

Layers |

8 |

|

|

Air System |

Operating Pressure |

kg/cm2 |

7~9 |

|

Low Pressure Air Consumption |

ltr/min |

3000 |

|

|

吹瓶压力 Blowing Pressure |

kg/cm2 |

20~30 |

|

|

高压耗气量 High Pressure Air Consumption |

ltr/min |

4800 |

|

|

Chiller |

操作压力 Operating Pressure |

kg/cm2 |

2~4 |

|

温度范围 Temperature Range |

℃ |

10~12 |

|

|

消耗量 Consumption |

kcal/hr |

2000 |

|

|

流量 Flow Rate |

ltr/min |

350 |

|

|

Machine (Blower and Heater) |

主机尺寸 Main Machine Dimensions |

mm(L*W*H) |

3700×2150×2150 / 5500Kg |

|

上胚机尺寸 Preform Loader Dimensions |

mm(L*W*H) |

2350×1350×2650 / 550Kg |

Related Keywords