Glossy Cream Aluminum Sheet Plate 1.6mm 5052 H32

- Min. Order:

- 2 Ton

- Min. Order:

- 2 Ton

- Transportation:

- Ocean

- Port:

- Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHN |

|---|---|

| Productivity: | 1000 sheets / sheets per Month |

| Supply Ability: | 500 sheets / sheets per month |

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW |

| HS Code: | 7606125900 |

| Transportation: | Ocean |

| Port: | Shanghai Port |

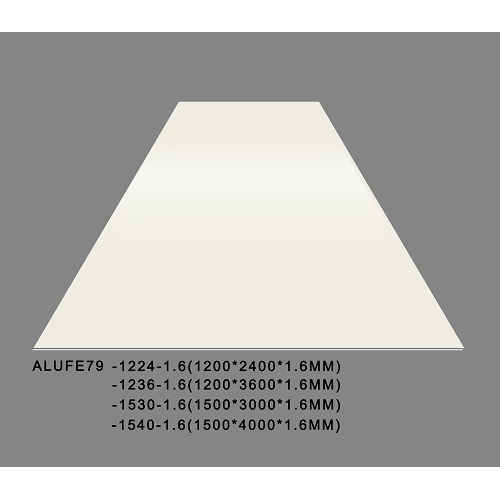

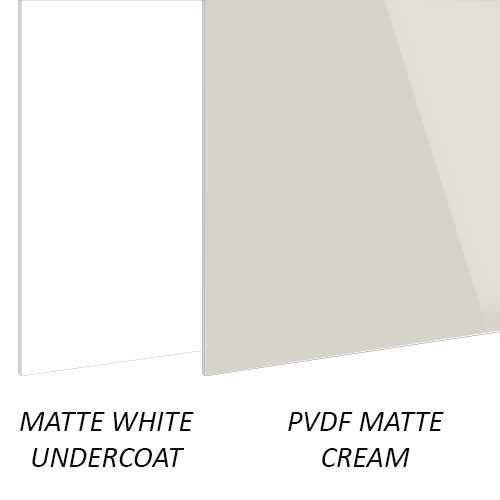

Glossy Cream Aluminum Sheet Plate 1.6mm 5052 H32:

1.1200 x 2400 x 1.6mm, FEVE Glossy Cream with clear masking film, back is Undercoat, with clear masking film, 10 years colour fast, Temper H32. 5052 is Marine grade Aluminum;

| REFERNCE | SIZE | THICKNESS | FOLDABLE |

| ALUFE79-1224-1.6 | 1200*2400*1.6mm | 1.6mm | YES |

Aluminum plates, also known as aluminum sheets, are basic raw form aluminum made into sheet form. Being sturdy, thin and lightweight, aluminum plates are used in a wide variety of industries and applications for its various properties. Coatings on aluminum plates can provide long-lasting materials for exterior use such as cladding, while the lightweight nature of very thin sheet aluminum makes it ideal for use in aluminum cans and other household products.

Applications

Uses of aluminum sheet include marine, construction,manufacturing, transport, industrial, automotive, food processing, heavy machinery and airline industries.

Aluminum sheet Finishes

|

Finish |

Description |

|

Anodising |

Protective aluminum oxide outer layer providing increased resistance to corrosion and wear. |

|

Bright Dipping |

Electro-brightening treatment to produce smooth surface with high lustre and “mirror” finish. |

|

Brushed Finish |

Distinctive appearance with uniform fine lines parallel to the brushing direction. |

|

Mill Finish |

Original nature of aluminum, where no chemical or mechanical finish is done on the surface. |

|

Powder Coating |

Durable film coating that can meet stringent performance criteria, offering a wide variety of colours. |

|

Pretreatment |

Etched or cleaned with an acidic or alkaline material before a pretreatment coating is applied. Applied coating enhances paint or powder adhesion and is corrosion resistant. |

Aluminum sheet - Advantages & Properties

Physically, chemically and mechanically, aluminum is a metal similar to steel, brass, copper, zinc, lead or titanium. It can be melted, cast, formed and machined in a similar way to these metals and conducts electric currents. In fact, often the same equipment and fabrication methods are used as for steel.

Light Weight

Aluminum is a very light metal with a specific weight of 2.7 g/cm3, about a third of that of steel. This cuts the costs of manufacturing with aluminum. Again, its use in vehicles reduces dead-weight and energy consumption while increasing load capacity. This also reduces noise and improves comfort levels.

Its strength can be adapted to the application required by modifying the composition of its alloys. Aluminum-magnesium-manganese alloys are an optimum mix of formability with strength, while aluminum-magnesium-silicon alloys are ideal for automobile body sheets, which show good age-hardening when subjected to the bake-on painting process.

Corrosion Resistance

Aluminum naturally generates a protective thin oxide coating which keeps the metal from making further contact with the environment. It is particularly useful for applications where it is exposed to corroding agents, as in kitchen cabinets and in vehicles. In general, aluminum alloys are less corrosion-resistant than pure aluminum, except for marine magnesium-aluminum alloys. Different types of surface treatment such as anodising, painting or lacquering can further improve this property.

Electrical and Thermal Conductivity

Aluminum is an excellent heat and electricity conductor and in relation to its weight is almost twice as good a conductor as copper. This has made aluminum the first choice for major power transmission lines. It is also a superb heat sink for many applications that require heat to be drained away rapidly, such as in computer motherboards and LED lights.

Reflectivity

Aluminum is a good reflector of visible light as well as heat, and that together with its low weight, makes it an ideal material for reflectors in, for example, light fittings or rescue blankets. Cool roofs made of coated aluminum are invaluable in reducing internal solar heat within a house, by reflecting up to 95% of sunlight.

Strength at Low Temperatures

In contrast to steel, which rapidly becomes brittle at low temperatures, aluminum shows increased tensile strength as temperatures drop.

Moreover, the metal itself is non-toxic and odorless, which makes it ideal for packaging sensitive products such as food or pharmaceuticals. The fact that recycled aluminum can be used reduces the carbon footprint for this stage of food and beverage manufacturers as well.

Non-magnetic

Aluminum is non-magnetic, making it useful for electrical shieldings as in computer disks, dish antennas, busbars or magnet housings.

Sound and Shock Absorption

Aluminum is an excellent sound absorber and is used for constructing ceilings. It is also used in auto bumpers due to its shock-absorbing properties.

Recyclability

Aluminum is 100% recyclable and recycled aluminum is identical to the virgin product. This makes it a much more cost-effective source material for production runs. The re-melting of aluminum requires little energy: only about 5% of the energy required to produce the primary metal initially is needed in the recycling process.

Hot product

Acrylic Plexiglass Sheet

Aluminum Sheets

Aluminum Composite Panel

PVC Foam Board Sheet

Polypropylene Sheets

Aluminum Panel Trims & Joiners

Related Keywords