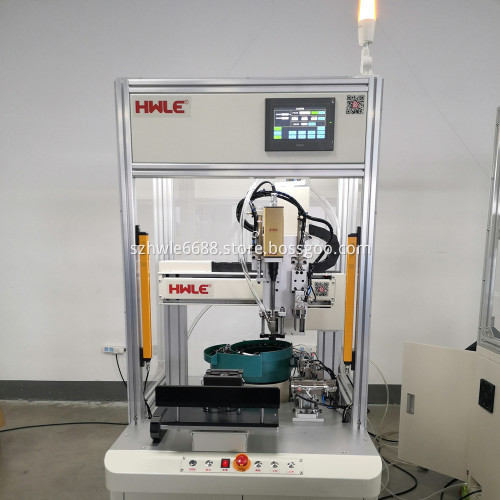

Three Axis Coordinate Automatic Locking Screw Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Shanghai, Qingdao, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou, China |

|---|---|

| Productivity: | 1000SETS |

| Supply Ability: | 1000 Sets |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU,Express Delivery,DAF,DES |

| Certificate: | ISO9001, ISO14001, CE |

| HS Code: | 84798999 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Shanghai,Qingdao,Shenzhen |

How much do you know about buying a servo automatic locking screw machine or an electric screwdriver machine?

Among the different types of automatic screw locking machines, there is a servo automatic screw locking machine. The function and efficiency of the servo locking screw machine and the ordinary electric screwdriver automatic locking screw machine are basically the same in production, the only difference is its locking system.

The power source of the servo lock screw machine adopts a servo motor, and the servo motor is used as the power source after deceleration for tightening and loading; the horizontal movement and vertical lifting device are used to drive the module to move up and down or left and right through pneumatic; the tightening torque is detected and fed back by the sensor, In addition, it realizes the real-time control of the tightening process by combining the control of the switching value of the cylinder and buttons.

The main advantages of robotic screw fastener machine are as follows:

1. High locking standard, precise torque control

The servo automatic locking screw machine has the function of precisely controlling the torque and angle. The torque control accuracy can reach ≤±1%F.S, the angle control accuracy can reach ≤±1°, and the calibration cycle can reach 2 million times. Assembly requirements. Preset tightening parameters.

2. Long service life, lower investment cost

The service life of the servo screwdriver is 3-5 times that of the ordinary screwdriver, and the failure rate is small.

3. Powerful monitoring function to meet high-quality production requirements

It can perform the locking task according to the given specific torque value. It has the functions of anti-wrong teeth, anti-leakage screwing, false torque, and alarm output.

4. Statistical analysis of data provides scientific basis for quality tracking

The servo screwdriver can display the tightening graph, torque value, angle value, time value and other parameters after each tightening, and analyze whether the tightening product is qualified. Provide data basis for quality control.

Related Keywords